Polypropylene and polycarbonate are two of the most commonly used thermoplastic polymers in various industries today.

Each material offers unique advantages, making them suitable for a wide range of applications, from packaging and automotive parts to protective gear and lightweight luggage.

This article aims to provide a comprehensive comparison of polypropylene vs polycarbonate by examining their key properties, typical uses, and environmental impact, helping readers make informed decisions when choosing between these versatile plastics.

What Is Polypropylene?

Polypropylene is a widely used thermoplastic polymer known for its lightweight, chemical resistance, and excellent heat resistance.

It is commonly employed in a variety of applications such as packaging materials, food containers, automotive components, and lightweight luggage.

Polypropylene’s flexibility and durability make it an excellent choice for products that need to withstand rough handling and exposure to various chemicals and solvents.

What Is Polycarbonate?

Polycarbonate is a durable and transparent thermoplastic polymer known for its exceptional strength, high clarity, and excellent impact resistance.

Commonly found in automotive applications, safety gear such as face shields, and outdoor applications, polycarbonate offers superior protection and rigidity compared to many other plastics.

Its unique properties, including resistance to rough handling and UV radiation, make it a great choice for frequent travellers seeking the right suitcase material that combines light weight with sleek style and security.

Polycarbonate can be shaped into a variety of products, from luggage shells to protective equipment, making it a perfect travel companion for those with specific needs and high standards.

Difference Between Polypropylene And Polycarbonate In Properties

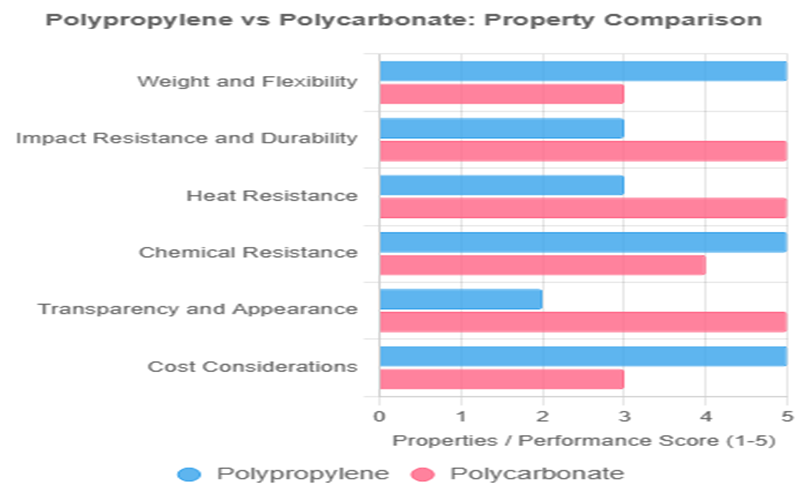

When comparing polypropylene and polycarbonate, several key property differences influence their suitability for various applications, from lightweight luggage to durable protective gear.

Weight

One of the most significant differences between polypropylene and polycarbonate lies in their weight.

Polypropylene is typically lighter than polycarbonate, making it an excellent choice for those seeking low weight luggage or products where minimizing mass is crucial.

On the other hand, polycarbonate, while slightly heavier, offers maximum durability and better protection under extreme pressure, making it a better choice for those who need rigid and robust luggage that can withstand rough handling and extreme temperatures.

Impact Resistance

Impact resistance is a crucial factor when choosing between polypropylene and polycarbonate, especially for applications like luggage and protective gear.

Polycarbonate generally exhibits superior impact resistance due to its molecular structure, allowing it to absorb and withstand high levels of force without cracking or breaking.

In contrast, polypropylene offers good resistance to impact as well but tends to be more flexible and less rigid, which allows it to absorb shocks by bending rather than resisting them outright.

Heat Resistance

Heat resistance is a critical property that differentiates polypropylene and polycarbonate, especially for applications exposed to high temperatures.

Polycarbonate can withstand high temperatures significantly better than polypropylene, with a melting point typically ranging from 225°C to 250°C.

In contrast, polypropylene has a lower melting point, generally between 130°C and 171°C, which limits its use in high-temperature environments.

Transparency

Transparency is a key distinguishing feature between polypropylene and polycarbonate.

Polycarbonate is renowned for its exceptional optical clarity and high transparency, making it ideal for applications requiring clear visibility, such as safety goggles, face shields, and certain types of luggage with glossy finishes.

In contrast, polypropylene is naturally translucent but not fully transparent. It often requires additives or specialized processing to achieve higher levels of clarity, which can increase production complexity and cost.

Suitcase Material

Choosing the right suitcase material is essential for meeting your travel needs and ensuring your belongings are well-protected.

Polypropylene suitcases are known for their lightweight design and flexibility, making them easy to handle and resistant to cracking under rough handling.

On the other hand, polycarbonate suitcases offer exceptional strength and maximum durability, with superior impact resistance that protects your belongings even under extreme pressure.

Various Applications Of Polypropylene

Polypropylene is a versatile thermoplastic polymer widely used across numerous industries due to its unique combination of properties.

Automotive Components

Polypropylene is extensively used in automotive components due to its exceptional combination of lightweight properties, chemical resistance, and impact resistance.

It is commonly found in parts such as bumpers, battery cases, interior trims, and dashboard components.

The material’s ability to withstand rough handling and exposure to oils, solvents, and varying temperatures makes it ideal for demanding automotive applications.

Consumer Goods

Polypropylene is widely used in consumer goods due to its excellent durability, lightweight nature, and resistance to chemicals.

It is commonly found in everyday products such as reusable food containers, household storage bins, toys, and furniture components.

The material’s versatility allows it to be easily shaped through injection molding and extrusion, enabling manufacturers to create a broad range of items with consistent quality and reliability.

Medical Applications

Polypropylene’s excellent chemical resistance and ability to withstand high temperatures make it a preferred material in the medical field.

It is commonly used to manufacture a variety of medical devices, including syringes, specimen containers, and surgical instruments.

Its resistance to sterilization methods such as autoclaving and chemical disinfectants ensures that medical equipment remains safe and durable.

Electrical Components

Polypropylene’s excellent insulating properties and resistance to heat make it a highly suitable material for use in electrical components.

It is commonly utilized in manufacturing electrical housings, connectors, and insulating parts, where durability and safety are paramount.

Additionally, polypropylene’s chemical resistance helps protect electrical parts from corrosion and degradation, extending their lifespan and maintaining consistent functionality.

Various Applications Of Polycarbonate

Polycarbonate is a highly versatile thermoplastic polymer known for its exceptional strength, impact resistance, and optical clarity.

Automotive Industry

In the automotive industry, both polypropylene and polycarbonate play vital roles due to their unique properties.

Polypropylene is extensively used for manufacturing lightweight automotive components such as bumpers, battery cases, interior trims, and dashboards.

Its excellent chemical resistance and ability to withstand rough handling and varying temperatures make it ideal for these applications.

Safety Gear

Polycarbonate is widely used in the manufacturing of safety gear due to its exceptional impact resistance and durability.

It is the preferred material for producing protective equipment such as helmets, face shields, safety goggles, and riot shields.

Thanks to its high clarity and toughness, polycarbonate provides excellent visibility while offering maximum protection against impacts, flying debris, and extreme pressure.

Electrical Components

Polycarbonate play important roles in the electrical industry due to their excellent insulating properties and resistance to heat.

Polycarbonate, on the other hand, is favored for producing durable and heat-resistant casings for laptops, smartphones, and other electronic devices.

Its superior impact resistance and ability to withstand high temperatures make it ideal for protecting sensitive electronics from rough handling and thermal damage, contributing to the reliability and performance of modern electrical equipment.

Outdoor Applications

Polycarbonate is widely recognized for its exceptional suitability in outdoor applications, thanks to its outstanding resistance to weathering, UV radiation, and extreme temperatures.

These properties make it an excellent choice for products such as roofing panels, skylights, and greenhouse coverings, where durability and clarity are essential.

Its ability to withstand high temperatures without deforming or losing strength ensures long-lasting performance in harsh environments.

Luggage Manufacturing

In the luggage industry, the choice between polypropylene and polycarbonate significantly impacts the quality and performance of suitcases.

Polycarbonate is favored for manufacturing hard-shell suitcases due to its exceptional impact resistance, high clarity, and ability to withstand extreme temperatures without losing strength or shape.

This makes polycarbonate suitcases highly durable and ideal for frequent travellers who require maximum protection for their belongings during rough handling and long journeys.

Environmental Impact Of Polycarbonate And Polypropylene

When choosing between polypropylene and polycarbonate, understanding their environmental impact is crucial for making an informed and responsible decision.

Polypropylene is known for being more easily recyclable compared to polycarbonate, which contributes to its growing popularity in sustainable manufacturing.

It is derived from hydrocarbon sources and can be reprocessed into new products with relatively lower energy consumption.

On the other hand, polycarbonate, while offering excellent durability and longevity, involves more complex recycling processes due to its chemical structure and the presence of bisphenol A (BPA).

Additionally, polycarbonate production tends to have a higher carbon footprint.

However, the longer lifespan and superior durability of polycarbonate products can reduce the frequency of replacement, potentially offsetting some environmental costs.

Both materials have their unique advantages and challenges in sustainability, and selecting the right material should consider the balance between performance needs and environmental responsibility.

Summary

In conclusion, the comparison between polypropylene and polycarbonate highlights their distinct properties and applications, making each material suitable for specific needs.

Polypropylene stands out for its lightweight nature, chemical resistance, and flexibility, making it an excellent choice for budget-friendly, low-weight luggage and various automotive components.

On the other hand, polycarbonate offers superior impact resistance, exceptional strength, and excellent heat resistance.

For a clear and concise comparison, a polycarbonate table outlining the key differences and properties of these materials can be highly beneficial in aiding an informed decision.

Frequently Asked Questions

What Are The Key Advantages Of Using A Thermoplastic Polymer In luggage Manufacturing?

The key advantages of using a thermoplastic polymer in luggage manufacturing are its lightweight, flexibility, chemical resistance, impact resistance, and durability.

Which Material Is Better For Frequent Travellers’ Luggage?

Polycarbonate is better for frequent travellers because of its maximum durability, superior impact resistance, and ability to withstand rough handling and extreme temperatures.

Can Polypropylene Withstand High Temperatures Like Polycarbonate?

No, polypropylene has a lower melting point (typically 130°C to 171°C) compared to polycarbonate (225°C to 250°C), so it is less suitable for applications exposed to high temperatures.

Is Polypropylene Recyclable Compared To Polycarbonate?

Yes, polypropylene is generally easier and more commonly recycled than polycarbonate, making it a more environmentally friendly option in terms of recyclability.

What Makes Polycarbonate Suitable For Outdoor Applications?

Polycarbonate offers excellent resistance to UV radiation, weathering, and extreme temperatures, maintaining its strength and clarity, which makes it ideal for outdoor uses like roofing panels and safety gear.