Polypropylene injection molding is a pivotal production process for creating quality injection molded parts across industries like automotive, packaging, and consumer goods.

Achieving the optimal PP injection molding temperature ensures dimensional accuracy, good chemical resistance, and a high-quality surface finish in injection molded products.

Precise temperature control of molding temperature, barrel temperature, melting point, and cooling rate minimizes defects such as sink marks, internal stress, moisture absorption, and thermal degradation.

This guide explores the PP injection molding process, critical temperature settings, mold design, and key considerations to deliver high-quality results while leveraging polypropylene’s low cost, low melt viscosity, excellent fatigue resistance, and excellent moisture resistance.

Understanding Polypropylene for Injection Molding

Polypropylene (PP) is a highly elastic thermoplastic valued for its low cost, low melt viscosity, excellent moisture resistance, and minimal moisture absorption, making it ideal for PP injection molding.

Understanding its properties and variants is crucial for optimizing PP injection molding temperature and ensuring superior outcomes in the production process.

Composition and Types of Polypropylene

Polypropylene is a block copolymer or random copolymer, available as isotactic PP or intercalated PP, offering good chemical resistance to non-oxidizing acids and organic solvents, but poor resistance to aromatic hydrocarbons and chromic acid.

Its low crystallinity ensures low temperature toughness and better optical transparency, making it perfect for sewage pipes, heating pipes, and food containers.

Filled polypropylene, reinforced with glass fibers or talc, enhances impact resistance, while random copolymer PP provides optical transparency for aesthetic injection molded products.

These properties make PP a cost-effective and versatile choice for PP production at high temperatures.

Role of Temperature in PP Injection Molding

The PP injection molding process hinges on precise temperature control to maintain low melt viscosity and lower melt finger temperature, ensuring smooth flow at the melting point (160-170°C for PP).

Incorrect molding temperature can lead to uneven cooling, causing sink marks, warping, stress concentrations, or increased moisture absorption in humid environments.

Proper barrel temperature and higher mold temperature ensure molten PP fills the mold cavity effectively, delivering dimensional accuracy and high-quality results while preventing thermal degradation at high temperatures.

The PP Injection Molding Process

The PP injection molding process transforms molten PP into quality injection molded parts through a series of controlled steps in the production process.

Mastering temperature settings at each stage is essential for efficient production and high-quality outcomes.

Stages of PP Injection Molding

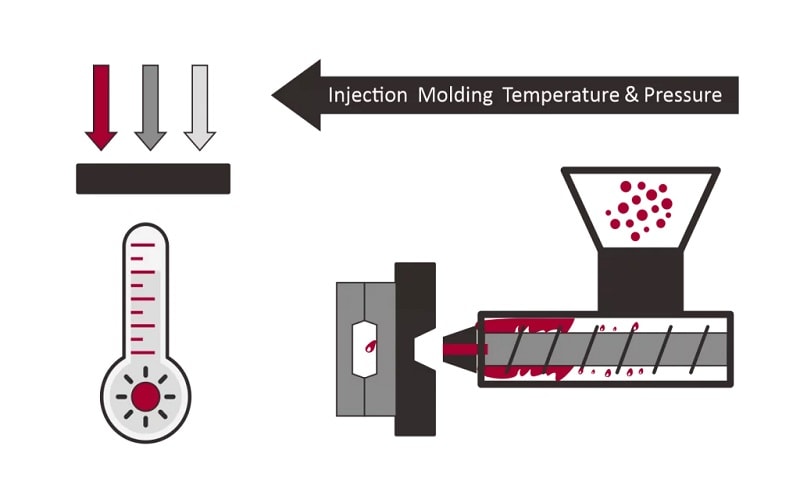

In an injection molding machine, PP pellets are heated in the barrel to the melting point (200-250°C), creating molten PP with low melt viscosity and lower melt finger temperature.

This molten PP is injected under high pressure or higher injection pressure into the mold cavity, filling it to form the desired shape.

Holding pressure and a controlled cooling rate solidify the part, minimizing internal stress, sink marks, and moisture absorption.

The mold design, incorporating generous radii to avoid sharp corners, ensures uniform wall thickness and dimensional accuracy. The injection molded part is then ejected, completing the cycle times.

Temperature Control Strategies

Temperature control is critical in PP injection molding to avoid thermal degradation at high temperatures above the decomposition temperature (260°C).

The barrel temperature optimizes low melt viscosity, while the higher mold temperature (20-60°C) promotes even cooling.

The cooling time balances speed cycle times with quality, preventing warping and ensuring lower shrinkage values.

Below is a table of recommended temperature settings for PP injection molding:

| Zone | Temperature Range (°C) | Purpose |

| Feed Zone | 180-200 | Preheats PP for smooth flow |

| Compression Zone | 200-230 | Ensures uniform melting point |

| Metering Zone | 220-250 | Optimizes low melt viscosity |

| Mold Temperature | 20-60 | Prevents sink marks and warping |

This table ensures dimensional accuracy, high-quality surface finish, and minimal moisture absorption in injected molded parts.

Benefits of Optimizing PP Injection Molding Temperature

Optimizing the PP injection molding temperature delivers significant advantages, enhancing production efficiency and product quality in the production process.

These benefits make PP a preferred material for industries.

Superior Mechanical and Chemical Properties

Polypropylene offers good chemical resistance to non-oxidizing acids and organic solvents, alongside excellent moisture resistance and low moisture absorption, making it ideal for sewage pipes, heating pipes, and food containers.

Proper molding temperature preserves excellent fatigue resistance and low temperature toughness, while filled polypropylene boosts impact resistance.

Random copolymer PP provides better optical transparency, enhancing aesthetic appeal in packaging.

- Good Chemical Resistance: Resists non-oxidizing acids and organic solvents for durability.

- Excellent Moisture Resistance: Minimizes moisture absorption in humid environments.

- Excellent Fatigue Resistance: Supports bending in living hinges or flexible parts.

- Impact Resistance: Enhanced by filled polypropylene for robust components.

High-Quality Surface Finish and Dimensional Accuracy

Controlled PP injection molding temperature ensures a high-quality surface finish and dimensional accuracy, critical for consumer goods like food containers.

Higher mold temperature and balanced cooling rate minimize sink marks, warping, and stress concentrations at high temperatures.

Mold design with generous radii and uniform wall thickness reduces sharp corners, enhancing surface finish and product quality.

Cost Efficiency and Production Speed

PP is inexpensive compared to other plastics, and its low melt viscosity and lower melt finger temperature enable speed cycle times, reducing production costs.

Optimized temperature settings prevent excessively high pressures, minimizing material waste and thermal degradation.

Lower shrinkage values ensure dimensional accuracy, making PP injection molding ideal for low volume production or medium production runs, delivering cost savings.

Challenges in PP Injection Molding Temperature Control

Achieving the optimal PP injection molding temperature requires overcoming challenges that impact production efficiency and product quality.

Addressing these ensures high-quality results in the production process.

Preventing Thermal Degradation and Defects

Thermal degradation occurs if the barrel temperature exceeds the decomposition temperature (260°C), compromising molten PP’s mechanical properties and increasing moisture absorption risks.

Uneven cooling can cause sink marks, warping, or internal stress, especially in irregular PP parts with sharp corners.

Mold design with generous radii and uniform wall thickness helps prevent warping and ensures dimensional accuracy at high temperatures.

Balancing Injection Pressure and Cooling Dynamics

Higher injection pressure ensures proper fill material flow into the mold cavity, but excessively high pressures can damage the injection molding machine or cause stress concentrations.

The cooling rate must balance speed cycle times with quality, as rapid cooling risks uneven cooling and sink marks.

Holding pressure during cooling supports lower shrinkage values, but requires precise temperature settings to maintain good chemical resistance to aromatic hydrocarbons or chromic acid.

Best Practices for PP Injection Molding Temperature

Implementing best practices in the PP injection molding process ensures quality injection molded parts with minimal defects.

These strategies focus on temperature control, mold design, and process optimization.

Optimizing Temperature and Pressure Settings

Set the barrel temperature between 200-250°C to achieve low melt viscosity and lower melt finger temperature, avoiding thermal degradation at high temperatures.

Maintain a higher mold temperature (20-60°C) for even cooling.

Use injection pressure and holding pressure to fill the mold cavity without excessively high pressures.

Monitor cooling time to balance speed cycle times with dimensional accuracy, ensuring a high-quality surface finish.

Effective Mold Design and Material Selection

Mold design is pivotal for PP production.

Incorporate generous radii to avoid sharp corners, reducing stress concentrations and sink marks.

Ensure uniform wall thickness to promote even cooling and prevent warping.

Select filled polypropylene for enhanced impact resistance or random copolymer for better optical transparency, tailoring the material to the final product’s needs.

These choices leverage PP’s excellent moisture resistance and good chemical resistance.

Applications of PP Injection Molding

Polypropylene injection molding produces injection molded products for diverse industries due to its low cost, durability, and versatility.

Optimized PP injection molding temperature ensures high-quality results across applications.

Automotive and Industrial Applications

PP injection molding creates automotive parts like bumpers, dashboards, and heating pipes, leveraging excellent fatigue resistance and impact resistance.

Sewage pipes benefit from PP’s good chemical resistance to non-oxidizing acids and excellent moisture resistance, minimizing moisture absorption.

Filled polypropylene enhances mechanical properties for industrial components like machinery fittings.

Consumer Goods and Packaging

Injection molded products like food containers and packaging utilize random copolymer PP for better optical transparency and low crystallinity.

PP’s low coefficient of friction and excellent resistance to organic solvents make it suitable for consumer goods like storage bins.

The low cost and speed cycle times support medium production runs, delivering quality injection molded parts.

Conclusion

Mastering the optimal PP injection molding temperature is crucial for producing quality injection molded parts with dimensional accuracy, high-quality surface finish, and excellent fatigue resistance.

By controlling barrel temperature, higher mold temperature, melting point, and cooling rate, manufacturers can minimize sink marks, internal stress, moisture absorption, and thermal degradation while leveraging polypropylene’s low cost, low melt viscosity, and good chemical resistance.

From automotive parts to food containers, the PP injection molding process delivers injection molded products that meet industry demands.

By implementing best practices in mold design, temperature control, and injection pressure, companies can achieve cost savings, speed cycle times, and high-quality results.