Polypropylene injection molding is one of the most common manufacturing processes used in plastics production.

Optimizing the PP injection molding temperature is essential to produce high-quality injection molded parts with precision, durability, and consistent performance.

Temperature management affects not only the final product’s dimensional accuracy and surface finish, but also cycle times, internal stress, and chemical resistance.

This guide provides a detailed exploration of the key considerations in temperature optimization during the PP injection molding process, explaining how to balance melting temperature, cooling rate, and mold temperature for superior results.

Understanding the PP Injection Molding Process

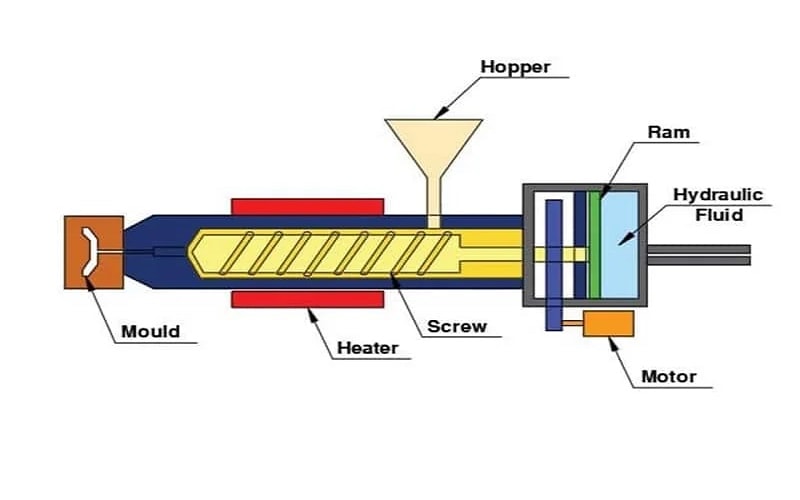

Before diving into temperature optimization, it’s important to understand the basic injection molding process.

PP injection molding involves heating polypropylene resin to its melting temperature, injecting the molten PP into a mold cavity under high pressure, and then cooling it to form a solid part.

The injection molding machine must maintain consistent temperature control throughout the cycle to prevent thermal degradation, uneven cooling, or surface defects.

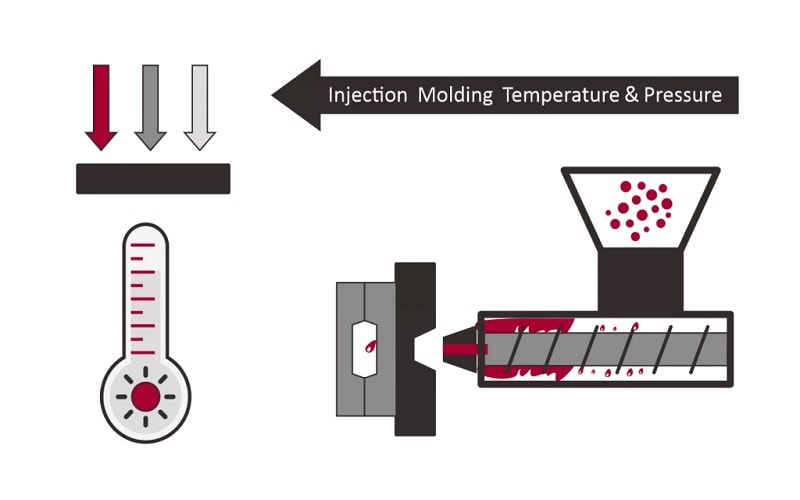

In the PP injection molding process, controlling the molding temperature and injection pressure is vital to achieve high-quality injection molded products.

The polymer’s low melt viscosity and excellent moisture resistance make it suitable for a wide range of applications, including food packaging, automotive components, and sewage pipes.

However, improper temperature settings can cause warping, sink marks, and irregular PP structure.

Key Temperature Parameters in PP Injection Molding

Several key temperature settings determine the outcome of the injection molded parts.

These include the barrel temperature, molding temperature, mold temperature, and cooling time.

Each plays a role in defining the PP’s flow characteristics, cycle time, and final product quality.

| Parameter | Typical Range (°C) | Notes |

| Melting Temperature | 220–250 | Higher melt improves flow but may risk thermal degradation |

| Mold Temperature | 30–70 | Higher mold temperature increases surface gloss and reduces shrinkage |

| Barrel Temperature | 200–240 | Maintained via heating pipes; affects molten PP viscosity |

| Cooling Time | 10–30 sec | Shorter times increase cycle speed but may cause internal stress |

Proper control of these temperatures ensures uniform melting, injection, and cooling.

Too low a melting temperature or uneven heating can lead to incomplete fill material, while excessively high temperatures can cause decomposition.

Balancing Melt and Mold Temperatures

The relationship between the melting temperature and mold temperature directly affects the dimensional accuracy and mechanical properties of the molded parts.

Molten PP must maintain adequate flow under higher injection pressure, but also solidify evenly to prevent warping and sink marks.

Using filled polypropylene or random copolymer PP can help reduce shrinkage values and enhance low-temperature toughness.

When the mold temperature is too low, the part may cool too rapidly, causing internal stress and poor surface finish.

Conversely, a higher mold temperature improves surface gloss and reduces the likelihood of stress concentrations, especially in complex mold designs with sharp corners or varying wall thicknesses.

Preventing Common Temperature-Related Defects

Common defects such as irregular PP structures, sink marks, and warping are often the result of improper temperature settings or inconsistent temperature control.

Uneven cooling or excessive holding pressure can lead to deformation and loss of precision.

Manufacturers should ensure uniform heat distribution and avoid sharp corners in the mold design to minimize stress points.

For applications that require excellent fatigue resistance, such as consumer products or sewage pipes, maintaining a stable cooling rate is essential.

Avoid excessively high pressures, and monitor the cooling time closely to achieve a balance between speed cycle times and part quality.

Engineering Considerations and Material Behavior

PP is a highly elastic thermoplastic with excellent resistance to many organic solvents and non-oxidizing acids, but it has poor resistance to aromatic hydrocarbons and chromic acid.

Isotactic PP offers better optical transparency and lower shrinkage values, while block copolymer PP supports bending and impact resistance under high stress applications.

Engineering teams must also consider low melt viscosity and low density characteristics of PP to reduce costs without sacrificing quality.

Precision in mold design and temperature control allows for better dimensional accuracy, a smoother surface finish, and reduced cycle times.

Temperature Optimization for Better Performance

Optimizing temperature control in the injection molding machine involves balancing several interdependent variables: melting temperature, injection pressure, holding pressure, and cooling time.

Each adjustment can impact the others, so a well-calibrated process and monitoring system are critical.

For example, higher injection pressure combined with slightly elevated mold temperatures can enhance material flow into complex mold cavities, resulting in better surface finish and fewer voids.

However, too high a temperature can cause thermal degradation or discoloration.

Comparing PP with Other Thermoplastics

Compared with other materials such as polyethylene, thermoplastic polyurethane, or rubber, polypropylene is relatively low cost and has excellent resistance properties.

It provides good chemical resistance, excellent moisture resistance, and supports bending and fatigue endurance in demanding environments.

PP’s low coefficient of friction and good optical transparency make it suitable for applications where smooth surface and visual clarity are required.

It is also inexpensive compared to other thermoplastics, making it ideal for large-scale production of injection molded products.

Temperature Balance in PP Production

In PP production, keeping the right temperature during the production process is key to getting strong and smooth plastic parts.

Polypropylene has a specific melting point, and it must be heated enough to melt properly but not so much that it reaches its decomposition temperature, where the material starts to break down.

If the temperature goes too high, the plastic can burn or lose its strength. If it’s too low, it may not fill the mold completely or create rough surfaces.

Another important factor is the lower melt finger temperature, which helps control how evenly the melted PP flows inside the mold.

Keeping this temperature stable helps prevent bubbles or uneven areas.

Even though PP has low moisture absorption, a small amount of moisture in the material can turn into steam at high heat and cause small defects. That’s why it’s best to dry the resin before molding.

By controlling these temperatures carefully, manufacturers can make the PP molding production process smoother, reduce waste, and ensure consistent quality in every molded part.

Conclusion

Getting the temperature right in PP injection molding is one of the best ways to make sure every part comes out strong, smooth, and consistent.

When manufacturers carefully control the melting temperature, mold temperature, and cooling rate, they can avoid common defects, save time during production, and keep the final parts accurate in size and shape.

The key is finding the right balance — not too hot, not too cold — so the plastic flows evenly and cools properly.

This kind of temperature control works for all types of PP products, from everyday consumer goods to technical components used in machines or packaging.

In short, successful PP injection molding comes down to good temperature management, the right material choices, and careful process monitoring.

When these factors work together, manufacturers can produce reliable, high-quality parts efficiently — meeting customer needs while keeping costs under control.