PVC molds shape Polyvinyl Chloride (PVC) into precise, durable products using injection molding. This method is efficient and popular in various industries.

In this article, we’ll explore PVC molds, types, properties, design tips, and their widespread applications of PVC mold technology.

What is PVC Mold?

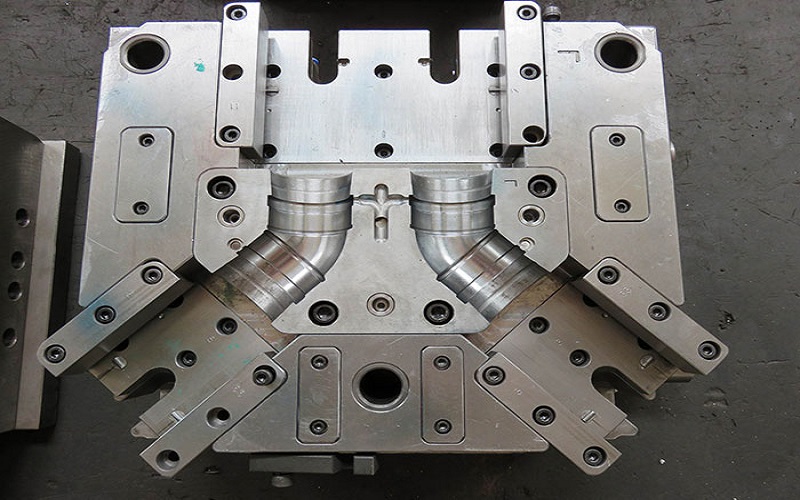

Polyvinyl chloride (PVC) is a widely-used industrial thermoplastic polymer known for its versatility and robustness. Injection molding [injection moulding], a manufacturing process that involves injecting molten material into molds, is particularly effective for PVC due to its ability to form complex shapes with high precision.

PVC injection molding is renowned for producing durable PVC plastic components efficiently and with great accuracy, making it a popular choice for applications involving colorless polymer and PVC molding. The use of a PVC injection molding machine [pvc injection molding machine] enhances this process, ensuring high-quality output.

PVC’s popularity spans various applications, from pipes and siding to containers and beyond. Utilizing PVC in the injection molding process enables manufacturers to produce a diverse range of PVC products that benefit from the material’s inherent properties.

Types of PVC for Injection Molding

There are two main types of PVC used for injection molding. These are rigid PVC and flexible PVC. Rigid PVC, often used in construction materials like doors and pipes, is known for its strength and durability.

Within rigid PVC, there are various grades, such as unplasticized (PVC-U) and modified (PVC-M), each tailored for specific applications, making it a rigid form of material. The process often involves liquefied PVC [liquefied pvc] to ensure proper molding.

Flexible PVC, on the other hand, finds its use in applications requiring pliability, such as medical tubing and automotive interiors. The flexibility of PVC can be adjusted by adding plasticizers, making it suitable for a wide range of uses. Selecting the appropriate type of PVC ensures the material meets the specific demands of the application.

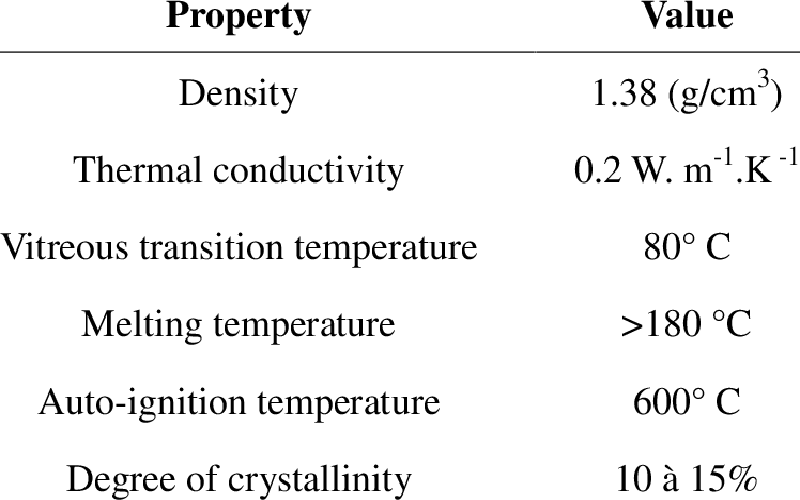

Properties of PVC Material

PVC’s properties make it an exceptional material for injection molding:

- It exhibits great dimensional stability.

- It has high resistance to impact, ensuring that molded products are both reliable and durable.

- The typical low shrinkage rate during injection molding is relatively low, ranging from 0.2% to 0.6%, which is essential for maintaining the dimensional accuracy of the final product.

In addition to its mechanical strength, PVC is highly resistant to various chemicals, including acids, bases, and alcohols, making it suitable for harsh environments.

Material melting temperature da > 180 degrees Celsius, allowing for effective processing during the injection molding process. Additives such as stabilizers and lubricants can further enhance PVC’s mechanical performance and ease of processing.

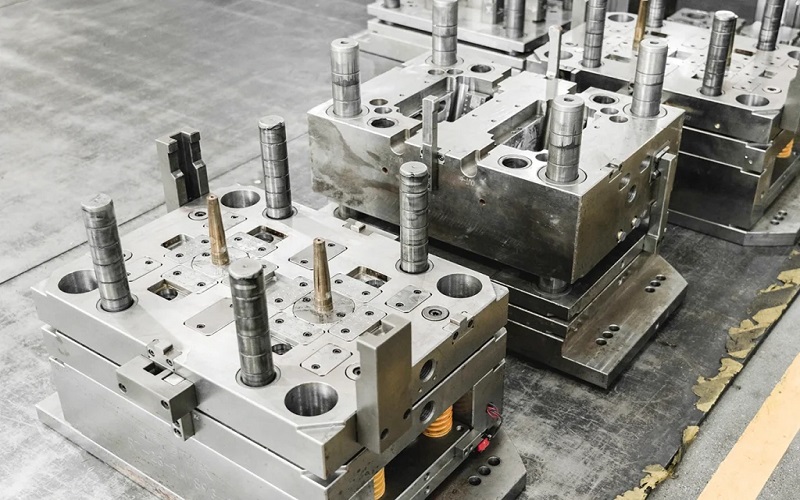

Design Considerations for PVC Molds

Designing molds for PVC injection molding requires careful consideration of several factors to ensure high-quality output, including mould design:

- Maintaining a uniform wall thickness to prevent defects in the final product.

- Using CAD and DFM tools to identify design flaws early.

- Ensuring effective material flow during injection.

Draft angles facilitate the smooth ejection of parts from molds by reducing friction during release. Key considerations include:

- A draft angle between 0.5% and 1% is recommended for PVC parts.

- Larger draft angles are required for longer part lengths.

- Effective gating and venting are vital to manage shrinkage.

- Proper gating and venting ensure the integrity of the molded parts.

Additionally, adding radii to sharp corners can enhance the flow of PVC during injection and minimize the risk of fractures in the molded parts. The recommended radius for inside and outside corners should be at least 25% of the wall thickness. Utilizing coring and ribbing can further reduce wall thickness while maintaining part strength, enhancing molding efficiency.

Advantages of PVC Injection Molding

PVC injection molding offers numerous benefits, making it a preferred choice in various industries. One of the significant advantages is its cost-effectiveness.

PVC is less expensive compared to other specialty plastics, making it a budget-friendly option, especially for high-volume production. Additionally, PVC has lower minimum order quantities, enhancing accessibility for small production runs.

Furthermore, PVC is highly versatile and suitable for a wide range of applications due to its important advantages:

- Its strong durability and chemical resistance

- A low melting point and good flow characteristics that enhance production efficiency by allowing rapid cooling and solidification

- Reduced waste production, making it an environmentally friendly option.

Challenges in PVC Injection Molding

Despite its advantages, PVC injection molding presents several challenges that must be addressed to ensure successful outcomes. One primary issue is thermal stability; improper temperature control can lead to the decomposition of PVC, releasing harmful gases like hydrochloric acid. Maintaining precise temperature control is critical to prevent this degradation.

Key considerations for PVC injection molding include:

- Proper drying of PVC before injection molding to prevent moisture absorption, which can cause cosmetic defects in the final product.

- Awareness of PVC’s low heat deflection temperature of 82°C, which limits its use in high-temperature applications.

- Use of additives such as lubricants and stabilizers to improve heat stability and avoid decomposition during the molding process.

PVC Injection Molding Process

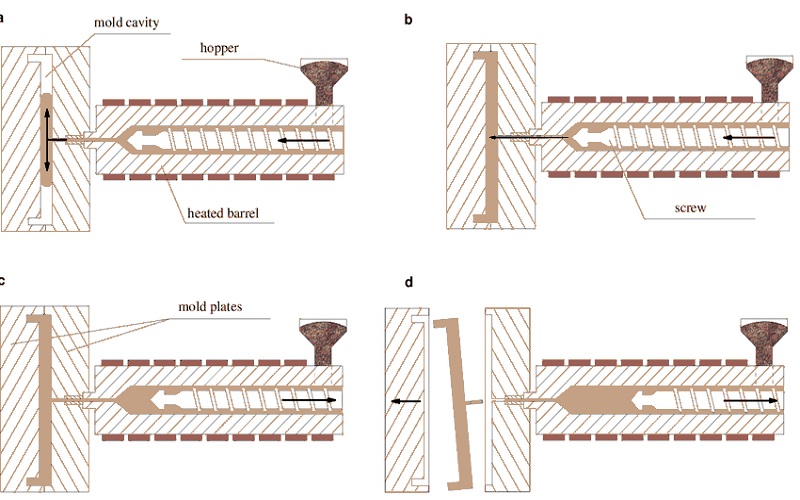

The PVC injection molding process involves several stages, each critical to producing high-quality molded parts:

- PVC material, typically in the form of PVC pellets or powder, is fed into the plastic injection molding machine.

- The material is heated until it reaches a molten state.

- Once liquefied, the PVC is injected into the mold under high pressure.

- The molten PVC fills the mold cavity and forms the desired shape.

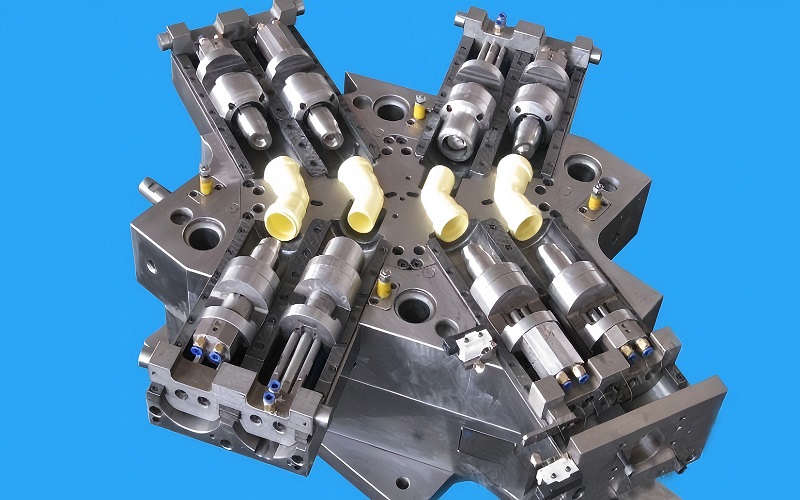

The PVC injection molding process involves the following steps:

- After injection, the injection mold is cooled to solidify the PVC, ensuring the part retains its shape and dimensions.

- Once cooled, the mold opens.

- The newly formed PVC molded parts are ejected into a collection bin for post-processing.

This process is optimized by adding a plastic part to enhance the fluidity of the PVC during injection, utilizing impact modifiers.

Temperature Control

Temperature control is paramount in the PVC injection molding process to prevent severe material degradation. Key points include:

- Excessive heating can cause chemical breakdowns, discoloration, and loss of material integrity.

- Maintaining the nozzle temperature approximately 10-20°C lower than the barrel’s end temperature is critical, as this relates to the mold temperature.

- This temperature control ensures a high-quality surface finish and helps avoid flow lines and surface imperfections.

Inaccurate temperature control can also lead to inconsistent flow of PVC, resulting in poor mold filling and potential short shots. Properly controlled cooling is equally important to prevent warping or dimensional inaccuracies in the final product.

Injection Pressure and Speed

Optimal injection pressure and speed are crucial for achieving consistent results in PVC injection molding. The injection pressure should be around 20-40 percent of the machine’s maximum capacity to ensure the material fills the mold correctly.

The required injection pressure is significantly influenced by factors such as the size and shape of the product. Additionally, the size of the gate opening also plays a crucial role.

The recommended parameters for PVC injection molding are:

- Screw speed: between 35-50 rpm

- Initial injection speed: set to slow to medium for optimal results

- Back pressure: controlled around 1 MPa to prevent overheating and decomposition of the PVC

- Higher injection rates: help reduce temperature fluctuations, ensuring consistent quality in the molded parts

Applications of Injection Molded PVC Parts

PVC injection molding’s adaptability makes it a key material in various sectors, including construction, healthcare, consumer goods, and industrial applications.

In the healthcare industry, flexible PVC is used for medical tubes, interior trim, and garden hoses. Its chemical and flame resistance make it suitable for safe electrical applications.

In construction, PVC is widely used for:

- – Plumbing and drainage systems due to its corrosion resistance and chemical resistance

- – Insulation in electrical wires (using flexible PVC)

- – Flooring for homes

- – Vinyl siding (used for durable, weather-resistant exterior cladding)

- – Machine housings (employed for robust, protective casings for equipment)

The material’s ability to be molded into diverse forms caters to various industrial needs, making it an effective electrical insulator due to its dielectric strength.

Best Practices for Successful PVC Injection Molding

To achieve high-quality results in PVC injection molding, working with an experienced molder is crucial. An experienced partner ensures adherence to PVC processing guidelines, which is critical for success. A manufacturing-ready design and a skilled production partner are essential for high-quality results.

Factors influencing lead time for PVC injection molding projects include complex parts, quantity, and finishing requirements, as well as screw length (which affects material flow and processing time in the injection molding machine) and diameter ratio (the ratio of screw diameter to barrel size, impacting melting efficiency and cycle time).

Proper finishing of the mold can eliminate the need for secondary operations on the produced parts, enhancing efficiency and reducing costs. Tighter tolerances can lead to increased costs, so balancing precision and budget is important.

Potential Alternatives to PVC

While PVC injection molding offers many benefits, there are alternatives that might be suitable for specific applications. High-Density Polyethylene (HDPE) and Polypropylene (PP) are two potential substitutes, each offering different properties.

HDPE is known for its high strength-to-density ratio, making it suitable for heavy-duty applications, while PP is valued for its versatility and resistance to chemical and thermal stress.

Other materials widely used in injection molding include:

- Acrylic

- Nylon

- Polypropylene Each brings unique advantages depending on the application’s requirements. Evaluating these alternatives can help manufacturers choose the best material for their specific needs.

Summary

PVC injection molding is a versatile and cost-effective manufacturing process widely used across various industries.

Its benefits include affordability, durability, and chemical resistance, making it an ideal choice for numerous applications. However, challenges such as thermal stability and moisture absorption must be managed carefully to ensure high-quality results.

Understanding the properties of PVC, the design considerations for molds, and the importance of precise temperature and pressure control can significantly enhance the efficiency and quality of the injection molding process.

By following best practices and considering potential alternatives, manufacturers can optimize their production and meet the diverse needs of their applications.

Frequently Asked Questions

What are the main types of PVC used in injection molding?

The main types of PVC used in injection molding are rigid PVC, utilized for construction materials, and flexible PVC, which is preferred for applications such as medical tubing and automotive interiors.

What are the key properties of PVC that make it suitable for injection molding?

PVC’s key properties for injection molding include excellent dimensional stability, high impact and chemical resistance, and minimal shrinkage, making it an ideal material for producing durable and precise components.

What are the advantages of PVC injection molding?

PVC injection molding is cost-effective and versatile, providing efficient production along with environmental benefits due to its low melting point and excellent flow characteristics.

What challenges are associated with PVC injection molding?

PVC injection molding presents challenges such as thermal stability concerns, moisture absorption, and the necessity of additives to enhance heat stability and prevent decomposition. Addressing these issues is crucial for achieving high-quality products.

What are some potential alternatives to PVC for injection molding?

High-Density Polyethylene (HDPE) and Polypropylene (PP) are viable alternatives to PVC for injection molding, providing unique properties tailored to specific applications. Consider these materials for your next project to enhance performance and sustainability.