In the competitive landscape of modern manufacturing, the ability to transition from a conceptual CAD model to a market-ready product is the ultimate differentiator.

Rapid injection molding (RIM) has emerged as the definitive methodology to bridge the critical gap between initial prototypes and full-scale production.

By integrating advanced rapid tooling with traditional manufacturing principles, this process allows engineers to bypass the exorbitant lead times and capital expenditures associated with traditional injection molding.

This guide explores the technical intricacies, material science, and strategic advantages of rapid injection molding services, providing a comprehensive roadmap for mechanical engineers and product developers.

Defining the Rapid Injection Molding Process

Rapid injection molding is a specialized subset of the injection molding process optimized for velocity and cost-efficiency.

While it utilizes normal injection molding equipment—specifically high-pressure injection molding machines—the fundamental departure lies in the philosophy of the mold design and the materials used for the tool.

The Essence of Rapid Prototyping

Essentially, rapid injection molding is a type of injection molding designed to produce parts quickly and efficiently, bridging the gap between initial prototypes and mass production.

It is primarily used for prototyping, research, and developmental applications that do not require hundreds of thousands or even millions of parts.

This makes it an indispensable tool during the prototyping stage, where functional testing is paramount.

How Rapid Injection Molding Works?

The core of rapid injection molding work lies in the use of rapid tooling .

RIM reduces tool lead times from months to weeks, enabling faster design validation and time-to-market.

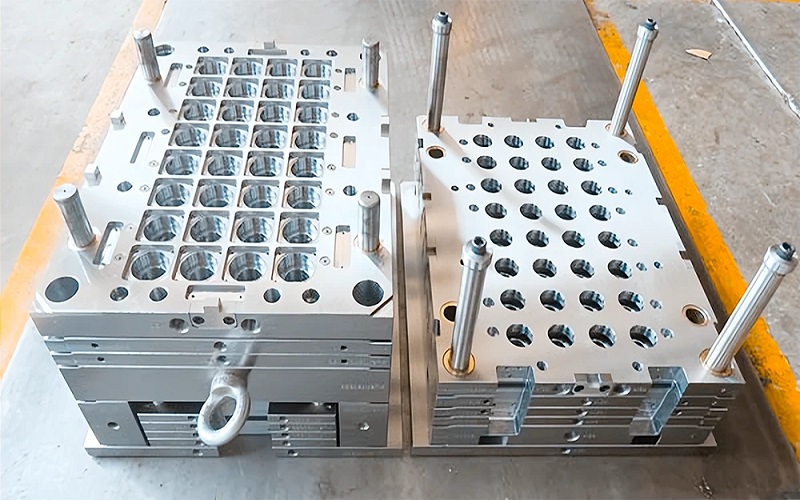

Instead of complex, multi-component production injection molds , engineers utilize aluminum molds or master unit die (MUD) systems.

Typically, these mold cavities are integrated into a master unit die (MUD) or master unit system. By using a master unit die universal frame, only the specific cavity inserts need to be fabricated, which drastically helps to reduce costs and setup times.

The manufacturing process involves injecting thermoplastic resins into a mold at high pressure, which then cools and solidifies to form the desired part.

Rapid injection molding primarily used for prototyping, research, and developmental applications that do not require hundreds of thousands or even millions of parts.

While the majority of rapid projects focus on thermoplastics, specialized industrial needs may utilize reaction injection molding, where thermosetting polymers are mixed at high pressure to create lightweight, durable components.

Rapid vs. Traditional Tooling:

The choice of tooling material in rapid injection molding is essential to balancing production speed, part quality, and budget.

Unlike production injection molds engineered for millions of cycles, rapid injection molding enables fast turnaround and low-volume production with significantly reduced lead times.

The reduction in concept-to-production lead time primarily comes from using softer mold materials, such as aluminum, which are less expensive and easier to machine than the hardened tool steels used in standard injection molds.

The high thermal conductivity of aluminum allows for faster cooling cycles, though it requires the strategic placement of cooling channels to ensure thermal uniformity and prevent part deformation during ejection.

| Feature | Rapid Injection Molding | Traditional Injection Molding |

| Tooling Material | Aluminum molds / P20 Soft Steel | Hardened steel molds |

| Lead Times | 1 to 15 days | 10 to 18 weeks |

| Typical Volume | 1 to 10,000+ units | High volume production (100k+) |

| Upfront Cost | Lower cost (Aluminum/Soft Steel) | High (Hardened Steel) |

| Mold Life | 2,000 to 100,000 cycles | Millions of cycles |

The Dominance of Aluminum Molds

Aluminum molds can be machined up to twice as fast as steel molds, making them a popular choice for rapid injection molding.

They offer superior thermal conductivity, which speeds up the cooling phase of the molding process.

- Lifespan: Typically around 2,000 shots.

- Suitability: Ideal for low-volume production and initial functional testing.

- Cost: The use of aluminum lowers upfront tooling costs significantly.

Soft and Semi-Hardened Steels

For applications requiring tight tolerances or higher durability, soft and semi-hardened steels like P20 and NAK80 are often preferred.

P20 steel molds generally last between 2,000 and 100,000 cycles depending on the plastic material used.

This makes them perfect for low-volume production runs or bridge tooling.

Advanced Techniques: EDM and 3D Printing

Electrical Discharge Machining (EDM): This is used to create intricate details in mold cavities that are difficult to achieve with traditional cutting tools, such as deep ribs or sharp internal corners.

3D-Printed Molds: In some niche cases, 3D-printed inserts offer increased design flexibility, especially for internal geometries where CNC machining is limited.

Advantages of Rapid Injection Molding

From a fiscal perspective, rapid injection molding allows engineers to test their designs with limited capital investment, rather than immediately committing to expensive production tooling for high-volume production.

The use of aluminum molds in rapid injection molding significantly reduces costs, for example by lowering mold costs and upfront tooling costs compared to traditional steel molds.

The high precision of rapid injection molding leads to minimal waste, aligning with sustainable manufacturing practices.

It saves on material costs by injecting the precise amount of plastic needed, resulting in very low scrap rates compared to subtractive methods, while using the same material as full-scale production.

Engineering Design for Rapid Molding (DFM)

To achieve high quality parts with high accuracy, the injection molded part design must be optimized for the rapid process. Design engineers need to balance speed against technical requirements.

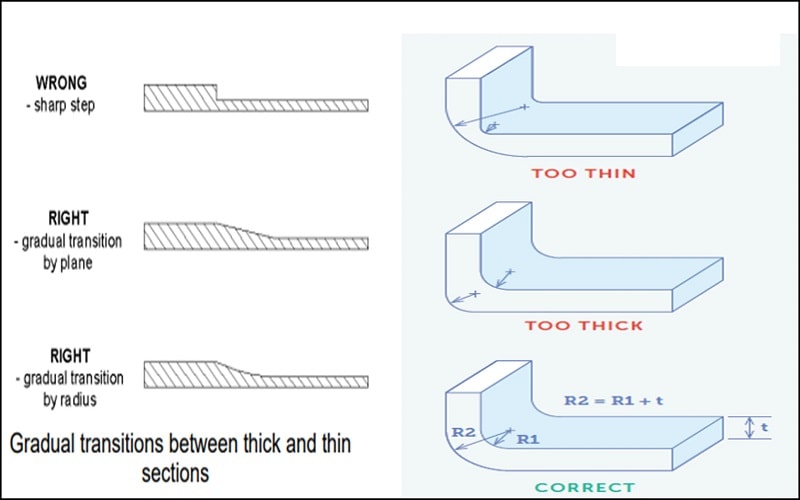

Wall Thickness and Uniformity:Maintaining a uniform wall thickness is paramount to preventing sink and warp, which directly impacts the final surface finish and aesthetic quality of the part. A uniform wall thickness of between 1.5 and 2.5 mm is recommended to help prevent defects and allow for uniform cooling.

While the wall thickness of a part is typically 1–3 mm, the optimal value depends on the selected plastic material. Inconsistent thickness leads to “sink marks” and internal stresses.

Draft Angles and Undercuts:Draft angles make it easier to remove the part from the mold without damaging it or creating defects such as scratch marks and deformation.

Furthermore, while complex molds can involve undercuts, these can complicate tooling and increase costs.

Manufacturers can handle them with proper design for manufacturing, often using sliding cores or manual pick-outs.

Structural Integrity:Ribs help reinforce flat surfaces and bosses provide anchor points for fasteners, improving strength with minimal material use.

These features ensure that even initial prototypes possess the mechanical properties required for real-world testing.

Material Selection and Production Integrity

One of the most significant advantages of RIM is that it allows for the use of the same material intended for full production.

This ensures that functional prototypes behave exactly like the final product and provides a seamless transition to full production once the design is frozen.

Rapid injection molding primarily uses thermoplastics, which may include commodity grades like polypropylene and engineering grades like nylon and polycarbonate.

Because it utilizes production grade materials, it is a “great choice for small batch production runs, limited-edition product releases, or pilot programs where a full investment in hardened steel tooling isn’t justified.

Rapid injection molding is ideal for functional prototypes made from production-grade materials, allowing for real-world testing without committing to long tooling timelines.

This ensures the initial prototypes exhibit the same thermal resistance and mechanical strength as the final production parts, especially when using resins reinforced with glass or carbon fibers.

Ultimately, choosing the best material for RIM depends on the desired end use of the product.

Manufacturing Industry-Specific Applications

Rapid injection molding can create the same functional plastic products as regular injection molding, including containers, connectors, brackets, custom products, plastic parts, and industrial equipment.

- Automotive Industry: Relies on rapid injection to prototype new designs and accelerate the product development process.

- Medical Devices: Relies on rapid injection to prototype new designs and accelerate the product development process.

- Consumer Electronics: Used to produce complex, high quality parts quickly, which is crucial during the FDA gating process.

- Aerospace: Beneficial for the quick creation of functional prototypes for testing and validation.

Bridge Tooling and On-Demand Manufacturing Process

Rapid injection molding is often used to bridge the gap between initial design and full-scale production and is a cost-effective way to test new products, materials, and design tools.

This strategy, known as bridge tooling, supports low-volume production runs for on-demand manufacturing.

Whether producing 1 or 10,000 units, RIM is designed for prototyping and low-volume production of 1 to 10,000+ units.

As such, rapid injection molded parts need tolerances that support alignment and assembly to ensure they function as intended in the field.

Rapid injection molding can create the same functional plastic products as regular injection molding, including containers, connectors, brackets, custom products, and industrial equipment.

Conclusion

Rapid injection molding has redefined the boundaries of the manufacturing industry.

By offering competitive pricing, high precision, and production-grade materials, it provides a pathway for innovation that traditional injection molding simply cannot match in the early stages of development.

Whether you are looking to produce 1 or 10,000+ units, rapid molding ensures that your injection molded parts are delivered with the speed and quality necessary to succeed in today’s fast-paced market.

It is not just about making parts fast; it is about making them right, at a lower cost, and with the flexibility to evolve.