Reaction injection molding (RIM) is a manufacturing process involving the mixing of two liquid polymers that react and harden inside a mold to create strong, lightweight, and customizable parts.

Unlike traditional injection molding, which melts thermoplastics, RIM relies on a chemical reaction, allowing for greater design flexibility and efficiency.

Understanding Reaction Injection Molding (RIM)

Developed in the 1960s, Reaction Injection Molding (RIM) is a manufacturing process that has stood the test of time, evolving to meet modern demands.

Unlike traditional injection molding, which relies on melting thermoplastics, RIM uses a chemical reaction to create thermosetting polymers that are injected into molds under high pressure.

This process involves mixing two parts of a polymer that react and cure when combined, allowing for the production of strong, lightweight, injection molded, and customizable parts, including those enhanced by insert molding and rigid foam.

RIM’s capability to create complex features like ribs, bosses, curves, and undercuts offers significant design flexibility, making it suitable for various applications.

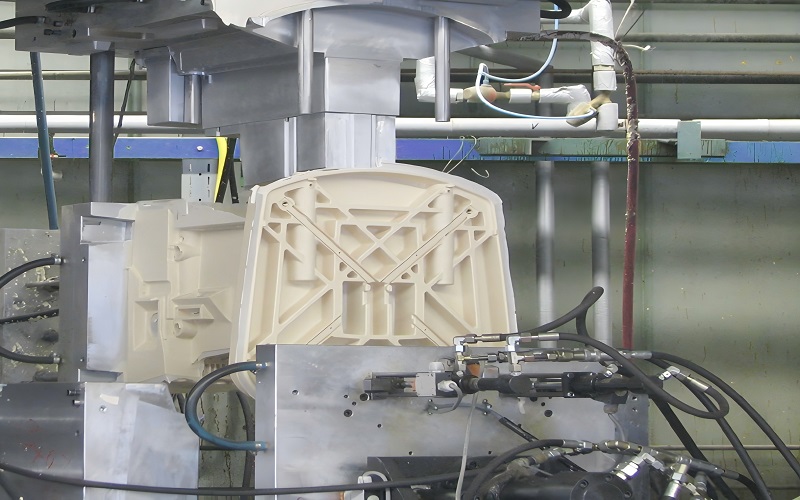

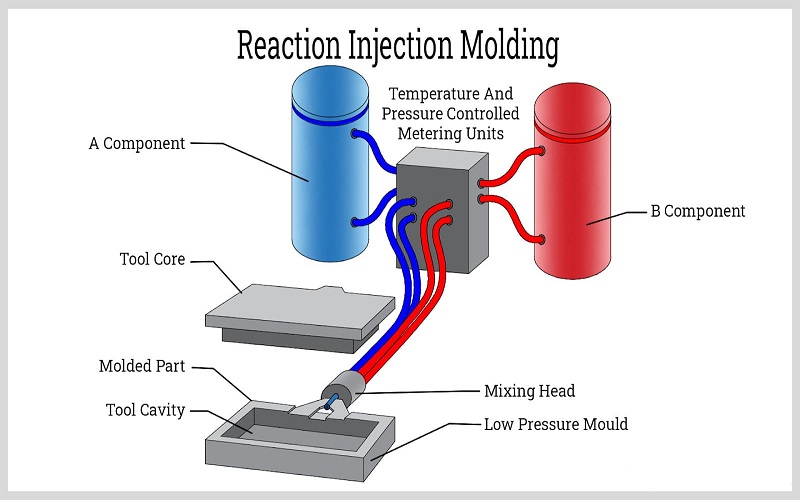

The RIM Process

The RIM process involves the following steps:

- High-velocity mixing of two liquid components: isocyanate and polyol.

- Injection of these ingredients into a mold.

- Undergoing an exothermic reaction, curing at approximately 180 degrees Fahrenheit (82 degrees Celsius) under low pressure.

- Solidification of the material into the desired shape.

This process produces parts with varied wall thickness and wall thickness intricate geometries.

RIM’s low-pressure and moderate-temperature curing process distinguishes it from other manufacturing methods of molding, including rim molds.

This approach not only reduces the risk of defects such as warping but also allows for the efficient production of large, complex parts, even under high temperatures, low temperatures, low viscosity, and mold cavity.

The flexible RIM process enables manufacturers to produce components that meet specific design and performance criteria, making it an invaluable tool in modern manufacturing.

Key Materials Used in RIM

The materials used in RIM are a critical aspect of its success. Reinforced Reaction Injection Molding (RRIM) takes the standard RIM process a step further by incorporating reinforcing fibers into the polymer mix.

These fibers, such as glass or carbon fibers, are blended with liquid polyol and isocyanate, enhancing the impact resistance and durability of the final products, often featuring a low density core and a high density skin.

By integrating these reinforcement fibers directly into the resin mixture, RRIM significantly improves the tensile strength and durability of the parts. This enhancement makes RRIM ideal for applications that require high-performance materials capable of withstanding demanding conditions.

As a result, RRIM broadens the range of potential applications for RIM, offering manufacturers even greater flexibility and capability.

Advantages of Reaction Injection Molding

The advantages of Reaction Injection Molding (RIM) are manifold, making it a preferred choice for creating large, lightweight, and durable components.

One of the primary benefits of RIM is its ability to produce parts that are stronger and more customizable compared to those made with traditional injection molding methods.

This is particularly useful for manufacturing large, thin-walled components that require complex designs.

RIM offers several advantages:

- Capability to handle varied wall thicknesses and produce intricate geometries, providing considerable design freedom.

- Suitability for a broad range of applications.

- Lower tooling costs compared to traditional injection molding.

- Cost-efficiency for large parts and complex designs.

Design flexibility and cost efficiency are critical aspects of RIM, explored in the upcoming sections.

Design Flexibility

A core feature of RIM is its exceptional design flexibility, which includes:

- Production of parts with intricate geometries and varied wall thicknesses, challenging to achieve with standard injection molding techniques

- A low-temperature injection and curing process

- The ability to create customized shapes and detailed designs

Advanced RIM techniques allow for the production of complex geometries and large components at reduced tooling costs.

This design freedom makes RIM ideal for applications requiring detailed specifications and unique shapes, enabling manufacturers to innovate and push design boundaries.

Cost Efficiency

While the initial setup costs for RIM can be high, the process offers substantial savings on per-part production costs, especially for medium to large runs.

This cost efficiency is due to the lower pressure requirements of RIM, which reduce tooling expenses and simplify the setup process. As a result, RIM becomes an economical choice for producing high volumes of parts with consistent quality.

Lower per-part costs during production make RIM a cost-efficient choice for manufacturers aiming to produce large quantities of parts without compromising quality.

This economic advantage, combined with the capability to create complex and lightweight parts, makes RIM attractive for industries looking to optimize production.

Applications of Reaction Injection Molding

Reaction Injection Molding (RIM) is utilized across a wide range of industries, thanks to its versatility and ability to produce high-quality, lightweight parts.

The automotive industry, in particular, has embraced RIM for manufacturing components such as bumpers, air spoilers, fenders, and body panels. Beyond automotive, RIM is also used in industries like sporting equipment, furniture, packaging, electronic device enclosures, and machinery housings.

The ability of RIM to create lightweight parts with high strength makes it ideal for applications that require durable and impact-resistant components.

The growing market for RIM, with an expected compound annual growth rate (CAGR) of 7.3% from 2026 to 2033, underscores its increasing importance and potential in various sectors.

Next, we will explore specific applications of RIM in the automotive and medical device industries.

Automotive Industry

In the automotive industry, Reaction Injection Molding (RIM) plays a crucial role in producing lightweight and durable components. The technology excels in creating complex automotive parts that need both strength and lightweight properties. Components commonly produced using RIM include:

- bumpers

- air spoilers

- fenders

- body panels

- trunk covers This showcases RIM’s versatility and effectiveness.

RIM’s ability to produce large parts with intricate shapes makes it ideal for automotive applications where design and performance are critical.

Additionally, items like instrument panels and door trims are manufactured using RIM, showcasing its wide-ranging applications within the automotive sector.

The technology’s impact resistance and lightweight properties contribute to improved vehicle performance and safety.

Medical Devices

The medical industry also benefits significantly from Reaction Injection Molding (RIM).

RIM is utilized to create durable, chemically resistant enclosures for medical devices, ensuring dimensional stability and longevity. It is particularly advantageous for components that require high durability and stability, such as heavy equipment consoles and medical device covers.

In the medical field, RIM is used to manufacture dimensionally stable and wear-resistant components, enhancing the longevity of medical devices.

This includes surgical tools and housing for diagnostic equipment, where precise stability is crucial. RIM’s use in medical applications highlights its ability to meet stringent performance and reliability standards.

Advanced RIM Techniques

As RIM technology continues to evolve, advanced techniques like Structural Reaction Injection Molding (SRIM) and Reinforced Reaction Injection Molding (RRIM) are being developed to further enhance the properties of RIM plastic parts.

These methods incorporate reinforcing agents and additives, including two components, to improve the strength, durability, and performance of molded components.

SRIM and RRIM represent significant advancements in RIM technology, offering manufacturers new ways to optimize their production processes and create high-performance parts.

Structural Reaction Injection Molding (SRIM)

Structural Reaction Injection Molding (SRIM) integrates fiber reinforcements such as glass or carbon fiber into the molding process, significantly enhancing the structural integrity and weight efficiency of the parts.

This method involves placing preformed fiber reinforcements within the mold, ensuring they are fully saturated during the injection process to maximize strength.

Incorporating these structural elements into the mold, SRIM enables the creation of strong, lightweight composite parts ideal for demanding applications.

Using fiber mesh as a reinforcing agent ensures high structural strength and durability, making SRIM valuable for producing high-performance components.

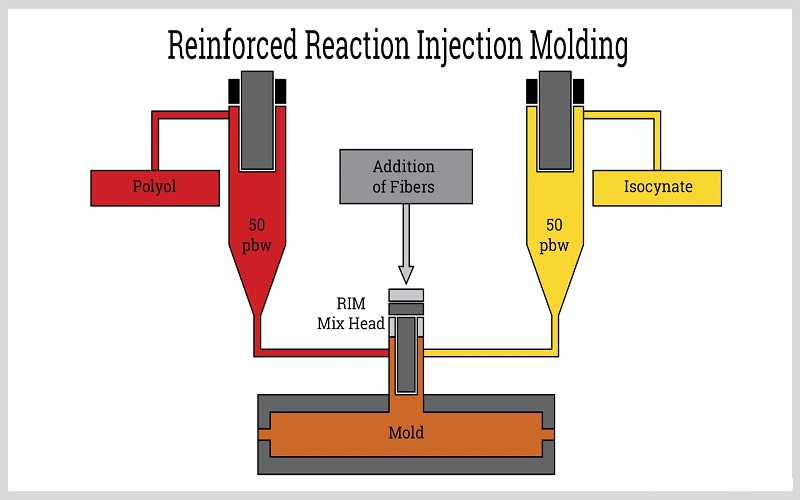

Reinforced RIM (RRIM)

Reinforced Reaction Injection Molding (RRIM) enhances the physical properties of molded parts by incorporating additives such as glass fibers into the polymer mix.

This reinforcement improves the impact resistance and tensile strength of the parts, making them suitable for demanding applications that require high durability.

In addition to polyurethanes, RRIM utilizes other thermosetting polymers like Dicyclopentadiene (DCPD) to achieve enhanced properties. Emerging technologies in RRIM are leading to improvements in efficiency and sustainability, further expanding the potential applications of this advanced polyurethane molding technique.

Comparing RIM with Other Molding Processes

Comparing Reaction Injection Molding (RIM) with other molding processes highlights its unique advantages and potential trade-offs.

RIM operates at significantly lower temperatures and pressures compared to other methods, which can improve efficiency and reduce production costs.

Next, we will compare RIM with thermoplastic injection molding and standard injection molding, offering a comprehensive understanding of how RIM stacks up against these common techniques.

RIM vs. Thermoplastic Injection Molding

RIM allows for a greater variety of materials because it uses thermoset materials that undergo a chemical reaction during the molding process.

In contrast, thermoplastic injection molding is limited to melting and shaping thermoplastics, which requires higher processing temperatures and pressures.

Key differences between RIM and thermoplastic injection molding:

- Thermoplastic injection molding is generally faster for high-volume runs.

- RIM offers more flexibility in material choice.

- RIM provides greater design capabilities.

The differences in materials and processes between RIM and thermoplastic injection molding make each method suitable for different applications.

RIM is ideal for producing complex shapes and large parts, while thermoplastic injection molding excels in high-speed production of simple, high-volume parts.

RIM vs. Standard Injection Molding

When comparing RIM with standard injection molding, one of the key differences is the cycle time.

RIM generally has a slower cycle time due to the chemical reactions involved, allowing for more intricate part designs without risking defects like warping.

Standard injection molding, on the other hand, typically has faster cycle times and lower costs per part once molds are established.

Despite the longer cycle times, RIM offers significant advantages in terms of design flexibility and the ability to create complex geometries.

This makes it a valuable option for applications that require detailed and unique designs, whereas standard injection molding may be more cost-effective for simpler, high-volume parts.

Future Trends and Innovations in RIM

The future of Reaction Injection Molding (RIM) is poised for significant advancements driven by emerging trends and innovations.

There is a growing focus on developing sustainable materials that reduce environmental impact while maintaining performance.

Additionally, automation and smart manufacturing technologies are being integrated into RIM processes, enhancing efficiency, precision, and scalability.

Let’s explore these future trends in greater detail.

Sustainable Materials

Environmental regulations are driving the adoption of eco-friendly materials in RIM, including bio-based and recyclable options. Materials like Sulapac are emerging as sustainable alternatives, featuring high bio-based content and the ability to biodegrade without leaving microplastics.

This shift not only adheres to regulations but also promotes a greener manufacturing process, attracting environmentally conscious consumers.

The introduction of biodegradable and bio-based materials is gaining traction in the RIM process to lessen environmental impacts. Integrating these materials allows manufacturers to produce high-quality, sustainable products that meet performance and environmental standards.

This movement towards sustainability signifies a major step forward in the evolution of RIM, aligning with global efforts to reduce the environmental footprint of manufacturing practices.

Automation and Smart Manufacturing

Automation technologies enhance production speed and reduce errors in RIM processes. Key benefits include:

- Integration of AI and IoT facilitates real-time monitoring and predictive maintenance.

- Boosting overall manufacturing efficiency.

- Ensuring continuous optimization of production parameters.

- Leading to higher quality and consistency in final products.

AI-based systems enhance real-time process optimization for RIM by analyzing production data for optimal settings. Smart manufacturing includes using IoT devices to monitor production parameters in real-time, improving efficiency.

These innovations promise to revolutionize the RIM industry, making it more efficient, precise, and capable of meeting the increasing demands of modern manufacturing.

Summary

Reaction Injection Molding (RIM) has demonstrated its versatility and effectiveness across various industries, from automotive to medical devices.

Its ability to produce lightweight, durable, and complex parts with considerable design flexibility and cost efficiency makes it a valuable manufacturing process.

The advanced techniques of SRIM and RRIM further enhance the properties of RIM parts, expanding its application potential.

As the industry moves towards sustainable materials and integrates automation and smart manufacturing technologies, RIM is poised for significant advancements.

These trends will not only improve the efficiency and precision of RIM processes but also align with global sustainability goals.