Rotational molding, also known as rotomolding, is a manufacturing process used to create hollow plastic parts through the rotational molding process. This method stands out for its ability to make complex shapes without using high pressure.

Ideal for producing items like storage tanks, toys, and automotive parts, rotational molding is both versatile and efficient.

This article will guide you through the process, its key components, materials used, and various applications.

Understanding Rotational Molding

Rotational molding, or rotomoulding, is a versatile and efficient process that involves heating and rotating molds to create hollow parts from polymer powder. Unlike other molding processes, rotational molding does not involve pressure, allowing for unique production capabilities and exceptional product shape options.

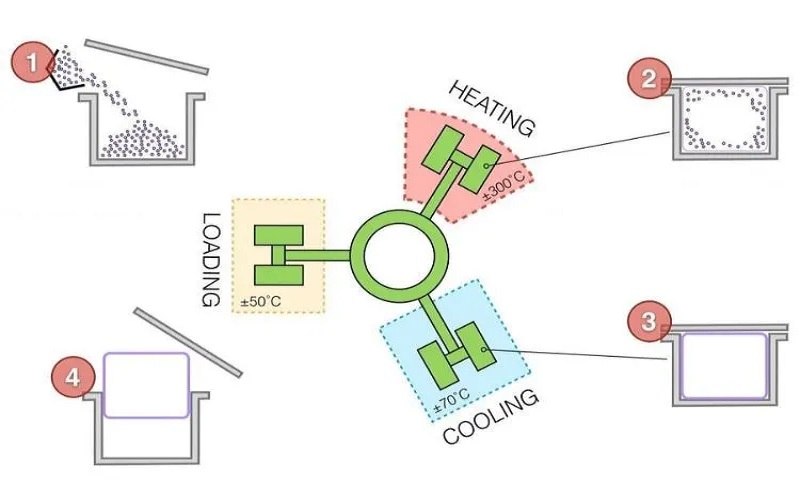

The process consists of four essential phases: loading the mold, heating it, cooling the molded product, and finally unloading it. This method is favored in the manufacturing industry for producing a wide array of items, from commercial storage tanks to toys and automotive components.

A solid grasp of rotational molding basics paves the way for exploring its components, machinery, materials, and applications.

What is Rotational Molding?

Rotational molding, or rotomoulding, involves heating and rotating molds to form hollow parts from polymer powder using the moulding method. This pressure-free technique enables a wide variety of product shapes and sizes.

Rotational molding can produce items ranging from small bottles to large storage tanks, offering unparalleled design freedom. This allows for the creation of complex shapes that are difficult to achieve with other molding methods.

Typical items produced include hollow products such as barrels, toys, and automotive components, showcasing the versatility and wide-ranging applications of rotational molding.

Historical Background

The origins of rotational molding date back to 1855 when it was first patented for creating artillery shells with uniform wall thickness. However, it wasn’t until the 1950s when plastics were introduced to the process, significantly expanding its applications and transforming it into the versatile manufacturing method we know today.

This historical evolution highlights the adaptability and continuous improvement of rotational molding, driven by technological advances and the growing demand for innovative plastic products. This historical context deepens appreciation for the process and its crucial role in modern manufacturing.

Key Components of Rotational Molding Machines

The effectiveness of rotational molding depends on several key machine components, including:

- Molds

- Ovens

- Cooling chambers

- Mold spindles

Each element is vital for ensuring the final product’s quality and consistency. For instance, mold spindles rotate to provide a uniform coat of plastic inside each mold, while the ovens and cooling chambers manage the critical heating and cooling phases.

The design and maintenance of these components are essential for optimizing the molding process and achieving high-quality results. Let’s delve into the specifics of each component to understand their functions and importance better.

Molds

Molds used in rotational molding are typically made from cast aluminum or sheet steel. Aluminum molds are particularly valued for their superior thermal conductivity, which enhances heating efficiency during the molding process. The design of the mold is crucial for ensuring product quality, incorporating features like vents to remove trapped air and prevent defects.

Good mold design enhances heating and cooling efficiency and ensures the final product has consistent wall thickness and structural integrity. Mastering the intricacies of mold design is fundamental for anyone aiming to excel in rotational molding.

Ovens and Heating Chambers

The oven in the rotational molding process is where the magic happens. It heats and rotates the mold to ensure proper part formation. Heating chambers are meticulously designed to maintain consistent temperatures throughout the process, preventing uneven melting of the polymer powder.

These chambers often use radiant heat to ensure an even temperature distribution across the molds, which is critical for achieving uniform wall thickness and high-quality products. Clamshell machines, for instance, allow for both heating and cooling within the same chamber, making them highly efficient for smaller production runs.

Precision and efficiency in the heating process are critical for the success of rotational molding.

Cooling Stations

Cooling stations are an essential component of the rotational molding process. They often utilize forced air or water sprays to expedite the cooling process and maintain part integrity during solidification. These stations may use both air cooling and water mist to achieve optimal cooling rates, ensuring that the molded plastic sets correctly and retains consistent wall thickness.

The cooling occurs in a dedicated chamber where the molded part solidifies as air or water mist is applied. Efficient cooling stations boost production efficiency and ensure the quality of the final product.

Types of Rotational Molding Machines

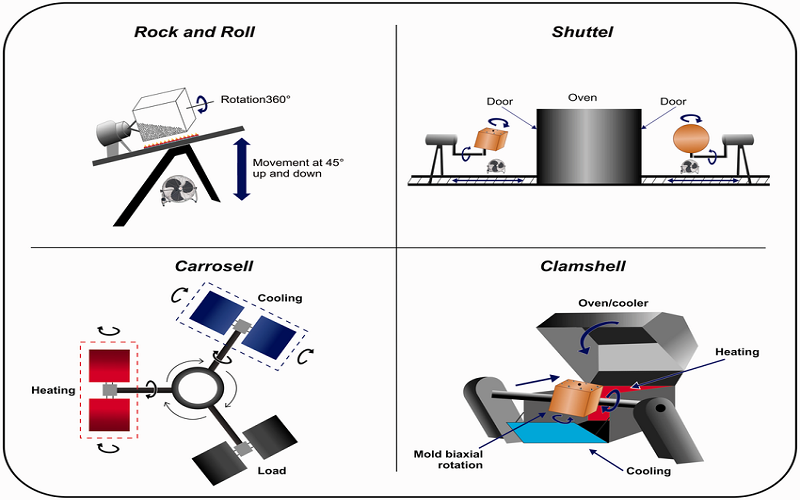

Rotational molding machines come in various types, each designed to meet specific production needs. The main types include:

- Clamshell machines

- Rock and roll machines

- Carousel machines

- Shuttle machines

Each machine type offers distinct benefits, from the compact efficiency of clamshell machines to the high-volume production capabilities of carousel machines.

Knowing the different machine types and their applications aids in selecting the right equipment for specific manufacturing needs, ensuring consistent quality and accuracy. Let’s explore each type to understand their unique characteristics and advantages.

Clamshell Machines

Clamshell machines are known for their compact design, making them ideal for facilities with limited space. These machines typically have one arm and an oven, with a lid that opens and closes, making them suitable for low-quantity production runs.

Clamshell machines take up less space than shuttle and swing arm molders, making them practical for smaller production environments. Their design ensures efficient heating and cooling, making them ideal for producing smaller batches of high-quality products.

Rock and Roll Machines

Rock and roll machines are specifically designed for producing large, durable parts. They feature a tilting oven and automatic cart movement, which are ideal for creating long, narrow products like tanks and vessels.

These machines utilize a rocking motion combined with rotation, ensuring even coating of the plastic within the molds. The rock and roll machine ensures efficiency in the production process.

Newer models use forced hot air for heating, enhancing efficiency and cutting energy costs. Rock and roll machines are particularly beneficial for large-scale production where durability and uniformity are critical.

Carousel Machines

Carousel machine, designed for high-volume production, features multiple mold stations rotating around two axes, significantly boosting production efficiency. Carousel machines can accommodate multiple molds at once, making them ideal for producing small to medium-sized items quickly and consistently.

Their capacity for continuous production cycles makes them ideal for large-scale manufacturing.

Shuttle Machines

Shuttle machines are known for their efficiency in high-volume production, featuring multiple molds on a moving platform. These machines utilize two arms that move molds between heating and cooling stations, minimizing idle time and significantly increasing production rates.

The design allows for seamless transitions between production stages, maintaining process efficiency and continuity. Shuttle machines are particularly useful for operations that require quick turnaround times and high production volumes.

Materials Used in Rotational Molding

Rotational molding utilizes a variety of materials, each offering unique properties suited for different applications. Common materials include polyethylene, PVC, nylon, and polypropylene, each with distinct advantages. For instance, polyethylene is the most commonly used material due to its cost-effectiveness and structural integrity.

Other materials like polycarbonate and nylon are valued for their strength and versatility, making them excellent alternatives for specific applications. Knowing the properties and applications of these materials is essential for selecting the right one for your production needs.

Polyethylene

Polyethylene (PE) is the primary material used in rotational molding, making it the cornerstone of the industry. Its popularity stems from its versatility, ease of molding, and ready availability. Polyethylene’s cost-effectiveness and structural integrity make it suitable for a wide range of applications, from storage tanks to toys.

Its properties, such as chemical resistance and durability, ensure that products made from polyethylene can withstand various environmental conditions, making it a go-to material for many manufacturers.

Other Materials

While polyethylene remains the most widely used material in rotational molding, other materials like polycarbonate and nylon offer unique benefits for specific applications. Polycarbonate is known for its high impact resistance and clarity, making it suitable for items that require visibility and durability.

Nylon, on the other hand, provides excellent chemical resistance and wear properties, making it ideal for products that face wear and tear. These materials broaden the scope of possible products, allowing manufacturers to choose the best material for their specific needs.

The Rotational Molding Process Step-by-Step

The rotational molding process involves several critical steps that ensure the creation of high-quality products. It begins with loading the mold, followed by heating and rotating the mold to distribute the material evenly, and finally, cooling and unloading the finished product.

Each step is essential for achieving the desired product characteristics, such as uniform wall thickness and structural integrity.

A detailed understanding of this production process helps optimize production and ensure consistent quality. Here’s a breakdown of each step and its importance.

Loading the Mold

The first step in the rotational molding process is loading the mold with the raw material, usually powdered polyethylene resin. This material is carefully placed inside the mold to ensure even distribution before the heating process begins. The mold is then sealed to prevent any leakage during the subsequent heating and rotating phases.

Proper loading ensures the final product has consistent wall thickness and uniformity.

Heating and Rotating

During the heating and rotating phase, the mold cavity is placed in an oven where it is heated and rotated on multiple axes. This rotation ensures that the material coats the inner mould surface of the mold evenly, adhering properly to the mold walls and maintaining consistent wall thickness.

Even material distribution is critical for the quality of the molded parts. This phase is vital as it determines the product’s structural integrity and final appearance.

Cooling and Unloading

Once the heating and rotating phase is complete, the mold is transferred to a cooling station where it is cooled using air or water sprays. This cooling process allows the newly formed part to shrink slightly, making it easier to remove from the mold. Controlled airflow, either through misting or blowing cool air, ensures proper solidification of the material.

After the part has cooled and solidified, it is unloaded from the mold, retaining its intended shape and quality. Efficient cooling and unloading are essential for maintaining production efficiency and product integrity.

Design Considerations for Rotational Molding

Designing for rotational molding involves several critical considerations to ensure the final product meets quality and functional requirements. Elements such as inserts, graphics, threads, undercuts, and multi-wall designs can enhance both the functionality and aesthetics of the product. The process allows for the creation of complex hollow parts without pressure, relying solely on gravitational forces.

Controlling the cooling rate prevents defects like warping and inconsistent wall thickness. Integrating molded inserts and various textures enhances usability and appeal.

Let’s delve into some specific design aspects.

Draft Angles

Draft angles are crucial in rotational molding, ensuring smooth release of parts from the mold, especially in areas where shrinkage occurs, thus reducing the risk of damage.

The effectiveness of draft angles varies depending on their application to internal or external surfaces. Well-designed draft angles ensure the product can be removed without compromising structural integrity.

Wall Thickness

Consistent wall thickness is vital for the product’s strength and durability. Variable thicknesses require precise control to maintain integrity. Thicker walls enhance strength but complicate molding and increase costs.

Innovations in temperature sensors and monitoring systems now allow for real-time tracking, optimizing wall thickness consistency and overall product quality.

Geometry and Structural Support

When designing for rotational molding, the geometry of the product plays a significant role in its structural support. Hollow ribs are preferred as they effectively enhance structural support without adding excessive weight. Optimal spacing for parallel walls should be five times the nominal wall thickness to ensure proper structural integrity and even heating and cooling.

These considerations help balance strength, weight, and manufacturability, ensuring the final product meets desired specifications.

Advantages and Limitations of Rotational Molding

Rotational molding offers a range of advantages, making it a preferred choice for many manufacturing applications. However, like any process, it also has its limitations. Knowing the benefits and challenges of rotational molding helps in making informed decisions for various projects.

Recent innovations have improved process efficiency and quality, but material constraints and cycle times remain concerns. Here’s a closer look at these aspects.

Advantages

One of the primary advantages of rotational molding is its low cost, as it requires less tooling and can be produced more quickly than other molding processes. This makes it a feasible option for short runs and rush deliveries, contributing to overall cost savings.

Additionally, parts can be molded as one piece, ensuring consistent wall thickness and strong corners, which enhances design flexibility. The process also allows prefinished pieces, like metal threads and colored plastics, to be added before pellets, offering flexibility and reducing material waste.

Limitations

Despite its many advantages, rotational molding does have some limitations. Thicker walls can lead to increased costs due to higher material usage and longer production times. Material type, stiffness, and required radii can affect melt-flow, impacting overall process efficiency.

Plastics may degrade during prolonged high-temperature exposure, affecting performance. The process is slower than other methods, and maintaining uniform wall thickness can be challenging due to temperature and material flow factors.

Recent Innovations in Rotational Molding

The rotational molding industry has seen several recent innovations aimed at enhancing process efficiency and product quality. Real-time process control using wireless temperature monitoring has become a breakthrough in the sector, allowing for precise control of mold temperatures and improving product consistency.

New heating methods have significantly reduced cycle times, enhancing efficiency while maintaining high quality. These advancements highlight the continuous evolution of rotational molding, driven by technological progress and the need for improved manufacturing processes.

Temperature Monitoring

Advancements in temperature monitoring have significantly increased the efficiency and use of rotational molding. Precise temperature control is crucial for ensuring uniform wall thickness and the overall quality of molded parts.

Recent developments in technology have led to more accurate temperature monitoring systems, allowing for real-time adjustments during the molding process.

These innovations ensure consistent product quality and reduce defects, making the process more reliable and efficient.

Cycle Time Reduction

Reducing cycle times is essential for improving the efficiency of the rotational molding process. One method currently being researched is mold pressurization during the heating phase, which has shown promise in significantly reducing cycle times.

Optimizing heating and cooling stages enhances productivity while maintaining product quality and structural integrity. These innovations are crucial for meeting production demands and staying competitive in the industry.

Applications of Rotational Molding

Rotational molding is used to manufacture a diverse range of products across multiple industries, highlighting its versatility and adaptability. From industrial applications like storage tanks and containers to everyday consumer goods such as outdoor furniture and toys, rotational molding proves to be an efficient and reliable manufacturing method.

The range of applications showcases rotational molding’s efficiency and adaptability in creating industrial and consumer products. Here are some specific applications.

Industrial Uses

In the industrial sector, rotational molding is vital for manufacturing items like large storage tanks and containers, which can range from small sizes to capacities over 20,000 gallons.

Industrial applications also include tanks for chemicals and agricultural products, highlighting rotational molding’s versatility and importance in producing durable components.

Consumer Products

Rotational molding is used to create a wide array of consumer goods, including playground equipment, toys, pool floats, and sports equipment, demonstrating its adaptability in producing high-quality products.

The ability to create intricate shapes and durable items makes rotational molding a preferred method for manufacturing many types of consumer goods.

Summary

In summary, rotational molding is a versatile and efficient manufacturing method that offers numerous advantages, from cost-effectiveness to design flexibility.

By understanding its key components, materials, and process steps, manufacturers can optimize production and ensure high-quality results. Recent innovations in temperature monitoring and cycle time reduction further enhance the process, making it more reliable and efficient.

As we look to the future, the continued evolution of rotational molding promises to deliver even greater advancements, driving the industry forward and opening up new possibilities for innovative product designs.

Frequently Asked Questions

What is rotational molding?

Rotational molding is an efficient manufacturing process that involves heating and rotating molds to produce hollow parts from polymer powder. This technique allows for the creation of complex shapes and sizes with uniform wall thickness.

What materials are commonly used in rotational molding?

Rotational molding commonly utilizes materials like polyethylene, PVC, nylon, and polypropylene, each providing distinct properties for various applications. These materials are chosen for their durability and versatility in producing molded shapes.

What are the key components of rotational molding machines?

The key components of rotational molding machines are molds, ovens, cooling chambers, and mold spindles, all essential for the molding process. Together, these elements ensure the efficient and effective production of rotationally molded products.

What are the advantages of rotational molding?

Rotational molding offers cost-effectiveness and design flexibility while producing parts with consistent wall thickness and robust corners. This makes it a highly advantageous manufacturing process for various applications.

What recent innovations have improved the rotational molding process?

Recent innovations in rotational molding, such as real-time temperature monitoring and cycle time reduction methods, have significantly enhanced both efficiency and product quality. These advancements are essential for meeting the evolving demands of the market.