Businesses frequently encounter a common challenge: how to strike the optimal balance between cost control, accelerating time-to-market, and maintaining high quality?

While traditional high-volume injection moulding and rapid prototyping offer significant advantages in unit cost, they suffer from issues such as prohibitively expensive steel moulds and the inability to guarantee consistent product quality during mass production.

This is where short run injection molding (also known as low volume injection molding) emerges as a critical strategic tool.

By offering a middle ground that balances quality, speed, and cost, this manufacturing process has redefined how companies approach product launches.

This guide explores the numerous benefits, technical intricacies, and the best applications of short run injection to help you determine if it is the ideal solution for your project’s success.

Understanding Short Run Injection Molding

To appreciate the value of short run molding, one must first understand the injection molding process at its core.

Plastic injection molding involves feeding plastic pellets into an injection molding machine, where they are heated until they become molten plastic.

This molten material is then forced under high pressure into a mold cavity.

Once the material cools and solidifies, the finished part is ejected using ejector pins.

In conventional injection molding, the focus is on high volume production.

To withstand the heat and pressure of producing millions of plastic parts, manufacturers use steel molds.

While durable, these steel molds are incredibly expensive and require long lead times to manufacture. For a startup or a company testing a niche market, these high tooling costs can be a non-starter.

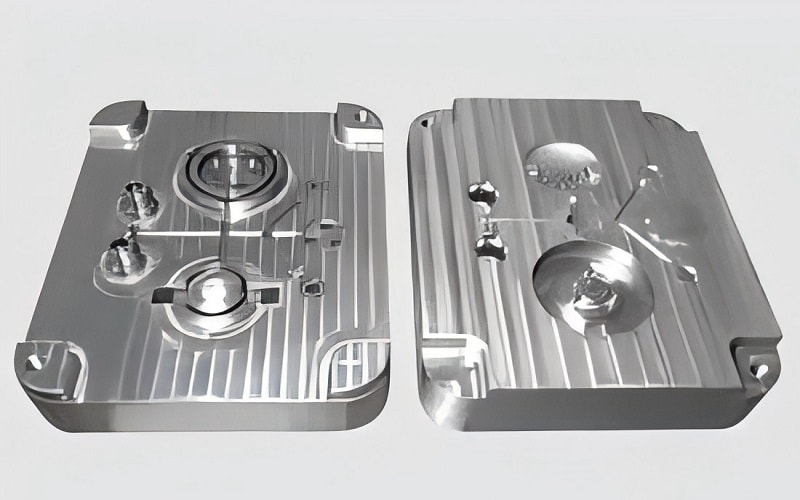

Short run injection molding focuses on producing small quantities, typically ranging from a few hundred to a few thousand units.

Instead of hardened steel, this process often utilizes aluminum molds or master unit die (MUD) systems.

This shift in tooling strategy allows businesses to produce parts with high precision and tight tolerances without the multi-month wait with mass production tooling.

Why Choose Low Volume Injection Molding?

For many businesses, the move to low volume production is driven by cost effectiveness and market demands.

Here are the primary advantages of integrating short run production into your development process:

Lower Upfront Costs

The most significant hurdle in injection molding is the expensive tooling.

By using aluminum molds, which are easier to cut via CNC machining, manufacturers can significantly reduce tooling costs.

This makes it a cost effective solution for projects that do not yet justify the investment in permanent steel infrastructure.

Faster Turnaround

In a competitive market, getting your market faster is a massive advantage.

Because aluminum molds are faster to produce than steel ones, lead times are slashed from months to weeks.

This allows for faster turnaround on first article inspection and subsequent production runs.

Bridge Tooling

Short run injection acts as “bridge tooling.”

It allows you to produce thousands of units to satisfy initial market demands while your high-volume steel molds are still being fabricated.

This ensures there is no gap in your supply chain.

Material Selection and Part Performance

Unlike 3d printing, which is excellent for rapid prototyping but limited in material properties, short run injection molding allows you to use the actual production-grade resins.

This means your injection molded parts will have the same level of part performance, strength, and finish as those produced in mass production.

Which Plastic Pellets Work Best for Short Run?

In small-batch injection moulding, selecting the appropriate plastic pellets is crucial to project success.

To reduce costs, ‘general-purpose plastics’ such as polypropylene (PP) may be employed. These flow readily into the mould cavity, thereby lowering production expenses.

For those in the automotive sector or medical device manufacturing, opt for “engineering plastics” such as ABS or polycarbonate.

These materials enable high precision and strict tolerance control.

Small-batch production serves as the optimal method for testing these materials, ensuring the finished product meets requirements before scaling up production to tens of thousands of units.

Key Technical Components of Short Run Molding

To achieve manufacturing efficiency in low volume, specific techniques are employed to keep production costs low.

Master Unit Die (MUD) Systems

A master unit or master unit die is a standardized mold base that remains in the injection molding machine. Only the specific mold cavity inserts are changed for different projects.

This significantly reduces the amount of metal required to produce molds, leading to lower costs for the client.

Aluminum vs. Steel Molds

Aluminum molds is best for short run applications. They dissipate heat faster, potentially shortening the molding process cycle time. They are easier to machine, reducing the development process time.

Steel molds, reserved for high volume production. While they offer the lowest per-part cost over a million cycles, their upfront costs are prohibitive for small quantities.

Design for Manufacturing (DFM)

In the run injection molding world, mold design is king.

Designers must account for how the molten material flows, where the ejector pins will sit, and how mold releases will be used to ensure the molded parts do not stick.

Even in short run, adhering to DFM principles ensures high quality parts and prevents failures during the manufacturing process.

Quality Assurance in Short Run Production

Short run injection maintains the same high quality as mass production through a rigorous development process.

By performing a first article inspection, injection molders verify that tight tolerances are met early on.

Since aluminum molds are easier to modify than steel molds, any design adjustments are handled quickly, ensuring the project’s success.

During the manufacturing process, critical variables—including the temperature of the molten plastic, mold cavity pressure, and ejector pins timing—are monitored to ensure consistency.

This streamlined validation makes low volume production an efficient, high-quality cost effective solution.

Top Applications for Short Run Injection Molding

Where does low volume injection molding truly used? While it can be used across almost any sector, the following industries find it to be an ideal solution.

Medical Devices

The medical industry often requires high precision and tight tolerances, but the actual production volume for specialized surgical tools or diagnostic equipment might be limited to a few thousand units per year.

Short run injection allows these companies to meet strict FDA requirements using production-grade materials without the waste of high volume setups.

Automotive Industry

The automotive industry frequently uses short run molding for high-end or limited-edition vehicle components.

It is also essential for producing replacement parts for older models where the production volume has dropped significantly, but the need for high quality parts remains.

Niche Markets and Consumer Electronics

For a new gadget targeting niche markets, low quantities are the norm.

Short run injection allows these businesses to test the water.

If the product is a hit, they can transition to mass production later; if not, they haven’t lost a fortune on steel molds.

Functional Prototyping and Testing

Before committing to a run injection of tens of thousands, engineers need to perform functional testing.

Rapid prototyping with injection molding provides parts that can be used for impact testing, thermal analysis, and fitment in real-world conditions—something 3d printing cannot always replicate.

Comparing Short Run to Other Processes

The table below explains the advantages of small-batch injection molding in production from different aspects such as cost, delivery time, and quality.

| Feature | 3D Printing | Short Run Injection | Conventional Injection |

| Tooling Cost | None | Low (Aluminum Molds) | High (Steel Molds) |

| Lead Time | Days | 2–4 Weeks | 8–12 Weeks |

| Part Quality | Variable | High Quality Parts | High Quality Parts |

| Production Volume | 1–50 units | 100 – Thousand Units | Tens of Thousands+ |

| Material Choice | Limited | Wide (Any Plastic Pellets) | Wide |

Maximizing Cost Effectiveness in Your Project

To keep your short run production a cost effective solution for limited quantities, you need to work cost effectively by making smart design and sourcing choices.

First, keep your mold design simple. Avoiding complex features like undercuts makes CNC machining for aluminum molds much faster and cheaper.

Second, before you spend money on metal tooling, use 3D printing to test your part. This ensures the project’s success without wasting money on a mold that needs fixing later.

Third, choose injection molders who specialize in low volume. They often use master unit systems, which saves you from paying for a full, brand-new mold base every time.

Finally, even if you are only making a few thousand units now, plan ahead. Talk to your supplier about how to move to mass production later so the transition is smooth and affordable.

Summary: Is Short Run Right for You?

Small-batch injection molding is incredibly useful for agile small businesses.

It allows you to produce high-quality products with a very limited budget, comparable to those produced on large factory assembly lines.

Whether you’re in the automotive industry, developing medical devices, or launching consumer products for a niche market, small-batch injection molding can provide the molded parts you need, ensuring project success.