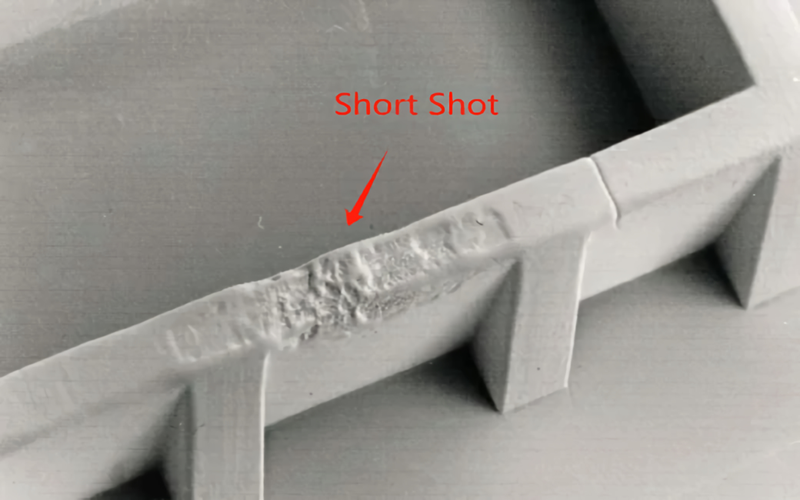

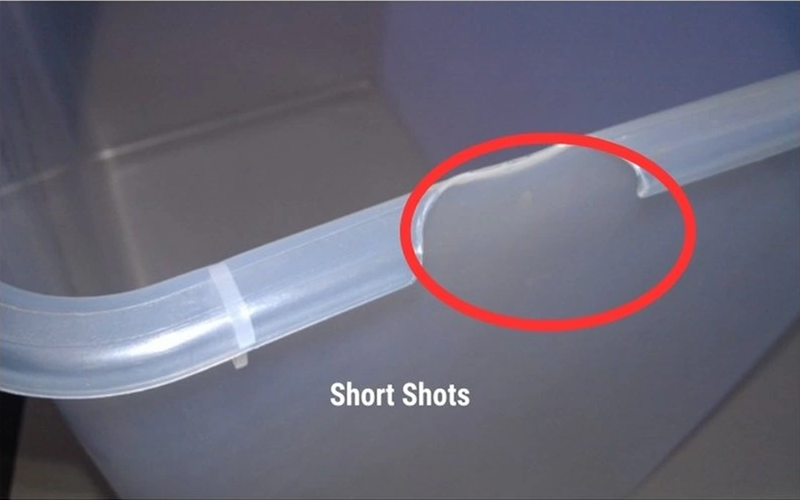

Short shot injection molding occurs when the mold cavity is not fully filled with molten plastic, resulting in defective and incomplete plastic injection molded parts.

This article will delve into the most common causes of short shots in injection molding and how to solve them.

From identifying the root cause to implementing solutions, you will gain valuable insights to enhance your injection molding process and ensure complete filling of the entire mold cavity, avoiding other problems associated with incomplete filling.

What Is Short Shot In Injection Molding?

A short shot in injection molding is a defect that occurs when the molten plastic does not completely fill the mold cavity, resulting in an incomplete or partially formed plastic part.

In these cases, a portion of the mold cavity remains unfilled, which leads to missing features in the molded part.

This issue, commonly called a short shot, is one of the most common injection molding defects and can significantly affect the quality and functionality of the final product.

Factors such as insufficient injection pressure, low mold temperature, improper injection speed, inadequate gate size, or material flow problems can all contribute to short shots.

Understanding what causes short shots and how to determine their root cause enables manufacturers to optimize the injection molding process, improve mold design.

Causes Of Short Shots In Injection Molding

Short shots in injection molding can arise from various factors, each influencing the flow of plastic within the mold cavity.

Insufficient Injection Pressure

Insufficient injection pressure is one of the most common causes of short shot injection molding defects.

When the injection pressure is too low, the molten plastic cannot be pushed effectively into every corner of the mold cavity, leading to incomplete filling and resulting in defective molded parts.

This lack of enough pressure prevents the plastic from flowing smoothly and filling the entire mold cavity, which is essential to avoid short shots.

To prevent this, it is essential to set injection pressure high enough to ensure the plastic flows smoothly, fills the entire mold cavity, and compensates for any pressure losses during the injection molding process.

Improper Injection Speed

Improper injection speed is a critical factor that can lead to short shot injection molding defects.

When the injection speed is too slow, molten plastic begins to cool and solidify before completely filling the mold cavity, resulting in incomplete parts.

Conversely, excessively high injection speed can cause turbulent flow, preventing the plastic from properly filling intricate sections of the mold and causing air entrapment.

Adjusting injection speed based on material properties, mold design, and wall thickness helps prevent short shots and other defects, contributing to higher quality plastic injection molded parts and reducing the risk of sink marks and other common injection molding defects.

Mold Temperature Issues

Mold temperature is a critical factor in the injection molding process that directly affects the flow and solidification of molten plastic within the mold cavity.

When the mold temperature is too low, the plastic cools prematurely, increasing its viscosity and hindering its ability to flow into all areas of the mold. Improper temperature control can also cause the plastic to break or develop stress-related fractures, further contributing to defects.

This insufficient heat can cause incomplete filling, resulting in short shot defects.

Maintaining an optimal mold temperature tailored to the specific plastic material and part design is essential to ensure smooth plastic flows and complete cavity filling.

High Viscosity Materials

High viscosity materials are a common cause of short shot injection molding defects because their resistance to flow makes it challenging for molten plastic to fill the entire mold cavity.

These materials flow more slowly when melted, especially in intricate or thin-walled mold sections, increasing the likelihood of incomplete filling.

To address this issue, manufacturers should carefully select materials with suitable viscosity ratings for their specific application and adjust processing parameters accordingly.

Contaminated Materials

Contaminated materials are a significant cause of short shot injection molding defects. Contaminated materials can obstruct flow paths during the injection molding process, leading to short shots.

Impurities in the materials, such as dust or foreign particles, can block the nozzle or obstruct the gate and runner, preventing the molten plastic from filling the mold completely.

Ensuring the purity of the melt, the air, and the vents is crucial to avoid these blockages and produce high-quality molded parts.

Regular cleaning of equipment and using high-quality raw materials maintain melt purity and ensure smooth flow, emphasizing the importance of material selection.

How To Avoid Short Shots In Injection Molding Process?

To effectively prevent short shots in injection molding, manufacturers should implement the following corrective actions.

It is important to correct and fix short shots by identifying and fixing the root causes, ensuring that the mold cavity is fully filled and defects are resolved.

Maintain Proper Mold Temperature

Maintaining the proper mold temperature is essential to prevent short shots in injection molding.

When the mold temperature is too low, molten plastic cools and solidifies prematurely, increasing viscosity and restricting flow, which leads to incomplete filling of the mold cavity.

Therefore, it is crucial to keep the mold temperature within the optimal range specific to the plastic material and part design.

Optimize Gate Size And Location

Optimizing the gate size and location is crucial in preventing short shot injection molding defects.

The gate serves as the entry point for molten plastic into the mold cavity, so its dimensions and position directly impact the flow and distribution of plastic.

By carefully designing the gate size to balance flow rate and pressure, and positioning it strategically—often at thicker sections of the part—manufacturers can ensure a smoother and more uniform filling process.

Ensure Adequate Venting

Adequate venting is essential in the injection molding process to prevent short shots caused by trapped air within the mold cavity.

When molten plastic flows into the mold, any air present must escape efficiently through well-designed vents. Otherwise, the trapped air creates pressure that blocks the plastic from filling the entire cavity.

Proper venting not only facilitates smooth plastic flow but also helps avoid other defects such as burn marks and incomplete filling.

Select Suitable Material Viscosity

Choosing the right material viscosity is critical to preventing short shot injection molding defects.

Materials with high viscosity resist flow, making it difficult for molten plastic to fill intricate or thin sections of the mold cavity completely. This resistance can lead to incomplete filling and defective molded parts.

By selecting materials with an appropriate viscosity level tailored to the specific mold design and part requirements, manufacturers can ensure smoother plastic flows and better cavity filling.

Regular Equipment Maintenance

Regular maintenance of injection molding equipment is vital to preventing short shot defects.

Over time, nozzles, gates, runners, and other critical components can accumulate residue, contaminants, or wear that obstruct the smooth flow of molten plastic.

These blockages increase flow resistance and can cause incomplete filling of the mold cavity. By implementing a routine cleaning and inspection schedule, manufacturers can ensure that all parts of the injection molding machine remain in optimal condition.

Quality Control And Inspection

Quality control and inspection play a vital role in the injection molding process, ensuring that each plastic injection molded part meets strict quality standards.

To avoid short shots and other defects, it is essential to closely monitor the injection molding process at every stage.

Additionally, monitoring the weight of injection molded parts can help identify short shots and ensure complete filling.

Regular inspection of molded parts allows manufacturers to quickly identify quality issues, such as incomplete filling or other defects, before they affect larger production runs.

Summary

In summary, short shot injection molding defects, often referred to as short shot issues, present many causes that can compromise the quality of plastic injection molded parts.

Understanding these causes from insufficient injection pressure and improper injection speed to mold temperature problems, high viscosity materials, contaminated materials, and even issues related to components like the check ring is essential for troubleshooting short shots effectively.

Identifying the root cause in the first place allows manufacturers to implement targeted corrective actions, such as adjusting injection parameters, optimizing mold design, and maintaining equipment properly, to prevent these defects.

By addressing short shot issues proactively, manufacturers can ensure complete mold cavity filling and produce high-quality molded parts.