Understanding side action injection molding is essential for manufacturers and designers aiming to create complex plastic parts with intricate features.

This specialized molding technique allows for the production of undercut geometries and detailed designs that traditional straight pull molds cannot achieve.

By integrating advanced mold surfaces and utilizing precise angle pins, side action injection molding overcomes the limitations posed by thermal expansion and complex part ejection.

In this article, we will explore the fundamentals of side action injection molding, its working principles, and the advantages it offers in modern manufacturing processes.

What Is Side Action Injection Molding?

Side action injection molding is a specialized manufacturing process designed to produce complex plastic parts featuring undercut geometries that cannot be formed using traditional straight pull molds.

This technique involves the use of mechanical side actions—such as cams, lifters, and sliders—that move perpendicular to the mold’s opening direction to create and release intricate undercut features during the molding cycle.

Although incorporating side actions increases tooling complexity and costs, it significantly enhances the mold’s capability to produce high-quality parts with tight tolerances and complex geometries.

This improvement ultimately leads to better customer satisfaction and reduces lead times in industries such as automotive, medical devices, and consumer goods.

Types Of Injection Molded Side Actions

Selecting the right type of side action is crucial in injection molding to minimize tooling costs and achieve the desired part complexity.

There are several types of side actions in injection molding, each with unique characteristics and applications.

Cams

Cams are vital components in side action injection molding that enable the creation of complex undercut features by moving mold surfaces laterally during the molding cycle.

This action mold mechanism uses angled pins to precisely control the action’s movement, allowing for the formation and release of intricate geometries that cannot be produced with a straight pull mold.

The cams’ smooth and reliable action’s movement ensures consistent thread production and high-quality molded parts with tight tolerances.

Lifters

Lifters are essential side action components used in injection molding to create internal undercut features that cannot be formed with a standard straight pull mold.

By incorporating lifters into the mold design, manufacturers can reduce or eliminate the need for secondary operations like machining or manual sourcing of additional components, leading to cost savings and improved production efficiency.

Proper integration of lifters requires careful consideration of the mold’s parting line and thermal conductivity of materials to ensure smooth operation and long-term durability of the mold components.

Sliders

Sliders are critical components in side action injection molding that facilitate the creation of complex external undercut features which cannot be formed using traditional straight pull molds.

These mechanisms move laterally into the mold cavity during the molding cycle, enabling the formation of intricate geometries such as slots, ribs, and external threads.

After the plastic part solidifies, sliders retract smoothly to release the molded part without causing damage to delicate features or the mold surfaces.

The use of sliders enhances manufacturing precision and allows for the production of high-quality parts with tight tolerances, reducing the need for secondary operations like machining or manual sourcing.

How Side Actions Work In Injection Molding?

Side actions are specialized mechanical components integrated into injection molds to enable the creation of complex undercut geometries that standard straight pull molds cannot produce.

These components, including cams, lifters, and sliders, move perpendicular to the mold’s opening direction, allowing the mold surfaces to form intricate features such as internal threads, snap-fits, and slot features.

During the molding cycle, side actions slide or pivot into position as the mold closes, creating the undercut geometry within the mold cavity.

After the plastic part solidifies, hydraulic or mechanical actuators precisely retract the side actions, freeing the molded part without damaging delicate features.

This controlled movement ensures consistent thread production and maintains tight tolerances, enhancing overall part quality.

While side actions add complexity to mold design and tooling costs, their ability to produce high-quality parts with complex geometries and reduce secondary operations makes them invaluable in modern manufacturing.

Applications Of Side Action Injection Molded Parts

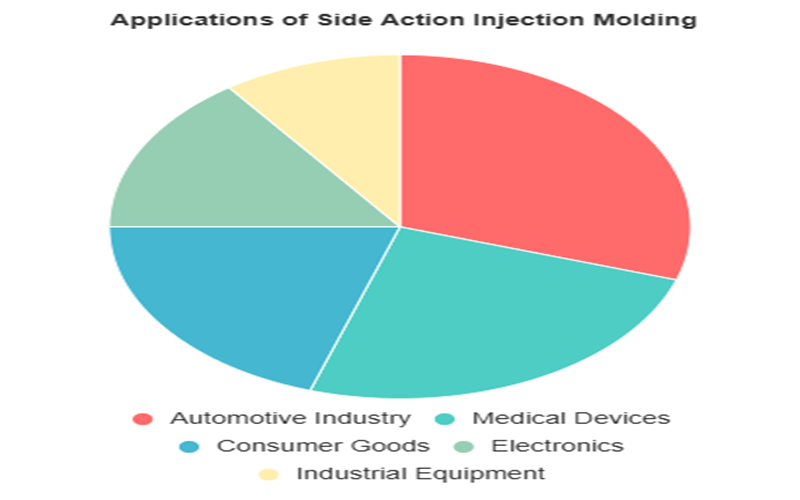

Side action injection molding is widely used across various industries due to its ability to produce complex and precise plastic parts with undercut features.

Automotive Industry

The automotive industry greatly benefits from side action injection molding by enabling the production of complex components with intricate undercut features, such as threaded parts, snap-fits, and precise slot features.

This advanced molding technique allows manufacturers to create durable, high-quality products with tight tolerances, improving assembly efficiency and overall vehicle performance.

Additionally, the use of advanced materials like aluminum and innovative mold designs ensures enhanced thermal conductivity and durability, meeting the rigorous demands of automotive applications.

Medical Devices

Side action injection molding is instrumental in producing high-precision medical device components that require intricate internal and external features, such as circular undercuts and threaded features.

This process ensures consistent quality and tight tolerances essential for biocompatible materials used in implants, surgical instruments, and diagnostic equipment.

Partnering with a trusted provider in medical molding guarantees superior product durability and customer satisfaction, supporting innovation in healthcare solutions.

Electronics

In the electronics industry, side action injection molding is indispensable for manufacturing complex components such as housings, connectors, and intricate internal structures.

These parts often require precise external undercut features and tight tolerances to ensure reliable assembly and optimal performance.

Additionally, the integration of advanced technologies and materials with excellent thermal conductivity ensures that electronic components meet stringent industry standards and customer satisfaction.

Advantages Of Side Action Injection Molding

Side action injection molding offers several significant advantages that make it an essential technique in modern manufacturing.

Enables Complex Geometries

Side action injection molding empowers manufacturers to produce highly intricate and complex geometries that are otherwise impossible with traditional straight pull molds.

By incorporating specialized side action components such as cams, lifters, and sliders, molds can form detailed external and internal undercut features including threaded components, snap-fits, and slot features.

Produce High Quality Products

Side action injection molding plays a vital role in producing high quality products by enabling precise control over complex geometries and undercut features.

The integration of side actions such as cams, lifters, and sliders ensures consistent thread production and accurate mold surface movements, resulting in parts with tight tolerances and superior surface finishes.

Increases Customer Satisfaction

Side action injection molding significantly increases customer satisfaction by enabling the production of complex, high-quality parts that meet precise specifications and functional requirements.

This advanced molding technique allows manufacturers to deliver products with intricate undercut features and tight tolerances, ensuring superior fit, finish, and durability.

Disadvantages Of Side Action Injection Molding

Disadvantages Of Side Action Injection Molding

Although side action injection molding offers many benefits, it also has several disadvantages that manufacturers should consider.

Increased Mold Complexity

Incorporating side actions into injection molds significantly increases mold complexity due to the addition of intricate mechanical components that must operate precisely and reliably.

This complexity demands advanced engineering expertise and high-precision machining to ensure that the side actions, such as cams, lifters, and sliders, function seamlessly with the main core and mold cavity.

Potential For Part Damage

While side action injection molding enables the production of intricate undercut features, the additional mechanical movements involved in retracting side actions during part ejection can increase the risk of damaging delicate molded parts.

These undercut features and mold surfaces require precise coordination to avoid scratches, deformation, or breakage.

Longer Cycle Times

One notable disadvantage of side action injection molding is the potential for longer cycle times.

The additional steps required to activate, position, and retract side actions—such as cams, lifters, and sliders—add complexity to the molding process.

These mechanical movements must be precisely synchronized with the mold’s opening and closing actions, which can extend the overall production cycle.

Future Trends In Side Action Injection Molding

The future of side action injection molding is set to be shaped by rapid advancements in technology and materials science, driving greater efficiency and innovation in manufacturing.

One key trend is the adoption of advanced alloys and specialized coatings for side action components, which significantly enhance durability and resistance to wear, thereby reducing maintenance frequency and extending mold lifespan.

Additionally, sustainability is becoming a major focus, with manufacturers increasingly utilizing recyclable plastics and energy-efficient molding techniques to reduce environmental impact.

Conclusion

Side action injection molding plays a crucial role in modern manufacturing, enabling the creation of complex geometries and undercut features that were previously unattainable.

Its ability to enhance design flexibility and reduce secondary operations makes it an invaluable tool for a wide range of industries.

As we look to the future, the integration of advanced technologies, additive manufacturing, and sustainable practices will further enhance the capabilities and benefits of side action injection molding.

By embracing this innovative approach, you can exceed expectations in part design and production services.

This allows you to create high-quality, functional, and aesthetically pleasing material products that meet the demands of today’s market with speed for your company.

This is achieved while considering the parting line in your designs, supported by a dedicated team.

Frequently Asked Questions

What Is Side Action Injection Molding?

Side action injection molding enables the production of intricate shapes and undercut features that are not achievable with standard molding techniques. This process is essential for creating more detailed and functional parts while allowing manufacturers and the company name to work with multiple supplier prospects to find the best fit for their project details.

How Do Side Actions Work In Injection Molding?

Side actions are crucial in injection molding as they enable the creation of complex shapes with undercuts that standard molds cannot achieve. To manage this process efficiently, manufacturers often provide a contact phone and require project details to coordinate mold design and production.

What Are The Types Of Side Actions In injection molding?

The primary types of side actions in injection molding are cams, lifters, and sliders. When selecting a supplier, companies typically attach file specifications and select company options based on their capabilities and experience.

What Industries Benefit From Side Action Injection Molding?

The automotive, medical, and consumer goods industries significantly benefit from side action injection molding, enabling the production of high-precision parts with intricate geometries and undercuts. These sectors often require strict confidentiality, keeping information private, and rely on trusted providers, sometimes located in Grand Rapids, to meet their manufacturing needs.

What Are The Future Trends In Side Action Injection Molding?

Future trends in side action injection molding focus on enhanced mold design and materials, automation integration, and sustainability through recyclable materials and energy-efficient processes. Additionally, the industry is moving towards reducing manually sourcing components by streamlining communication through contact name and contact email exchanges, allowing clients to send requests seamlessly and securely.