What makes silicone foam essential in various industries? Known for its insulation and sealing abilities, silicone foam is a lightweight, durable material used in automotive, electronics, and construction sectors. This article explores its properties, benefits, and top applications.

Understanding Silicone Foam

Silicone foam is an essential material in various industries, including concrete and transportation applications, primarily composed of silicone resin, fillers, cross-linking agents, and catalysts. Its unique composition grants it a range of properties that make it suitable for numerous applications, such as air barrier systems across different segments.

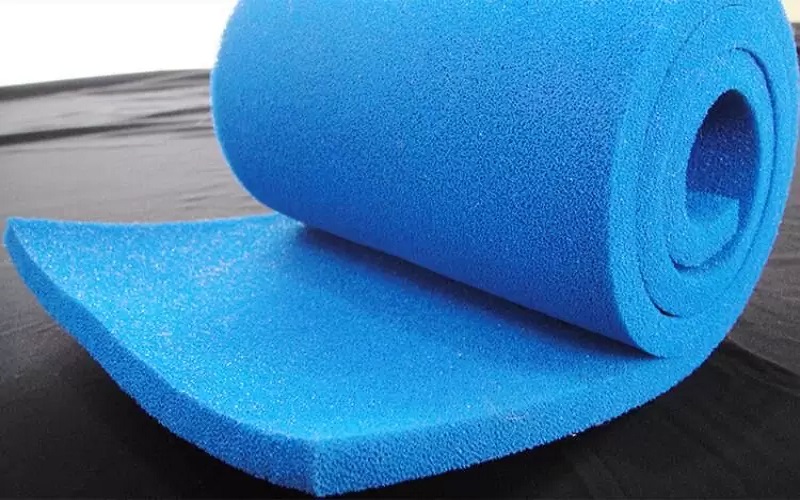

Silicone foam distinguishes itself through its low density and high porosity, which typically comprises 75-95% void spaces, allowing for excellent thermal and acoustic insulation, making it a key component in a distributor’s product line for site applications.

The versatility of silicone foam extends to its cellular structure, which can be either open or closed cells, each offering distinct benefits. We will delve into the properties and types of silicone foam, highlighting why this material is indispensable in today’s industrial landscape, particularly for concrete sealing, air barrier systems, and transportation segments at construction sites.

Properties of Silicone Foam

Silicone foam is renowned for its remarkable properties, including its ability to withstand extreme temperatures and harsh conditions without deteriorating.

This material’s high porosity and low density make it an excellent insulator, ideal for applications requiring thermal stability and resilience in facilities and residential websites across the USA, reflecting industry pride in quality manufacturing.

Additionally, mildew resistant silicone sealants made from silicone foam offer superior performance in maintaining airtight and watertight seals, ensuring the longevity and durability of various structures for builders, with competitive pricing and a range of compatible accessories, showcasing USA-made pride.

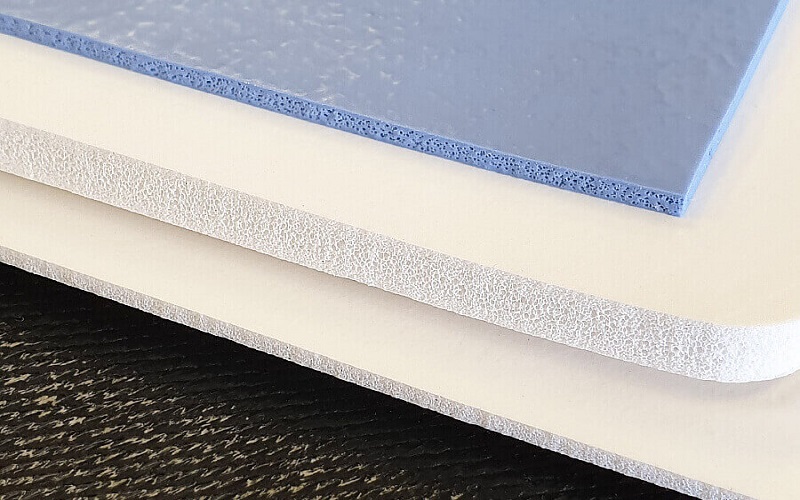

Types of Silicone Foam

Silicone foam is available in different forms, characterized by its cellular structure. Open-cell silicone foam allows for air permeability, making it suitable for applications where breathability is essential in residential websites in the USA.

Conversely, closed-cell silicone foam provides better moisture resistance and thermal insulation, making it ideal for sealing and protective applications in facilities constructed by builders with pride.

These variations enable manufacturers to tailor a variety of silicone foam products to specific needs, enhancing their utility across diverse industries, with pricing structures and accessories designed to meet market demands, reflecting the USA’s pride in innovation.

Applications of Silicone Foam

Silicone foam’s flexibility and resilience make it a go-to material for a wide array of applications. It is primarily utilized for gasketing and insulation due to its ability to absorb shocks and dissipate impact energy. American Sealants, Inc. is one of the leading producers of silicone foam products, catering to various industries with tailored solutions.

The automotive, electronics, and construction industries particularly benefit from silicone foam’s unique properties. We’ll examine specific applications within these sectors, showcasing how silicone foam enhances performance and reliability.

Automotive Industry

In the automotive industry, silicone foam plays a crucial role in ensuring the functionality and durability of vehicle components. Gaskets made from silicone foam prevent leaks and protect against environmental factors, contributing to the longevity of automotive systems.

Additionally, silicone foam provides effective wire protection, safeguarding electrical systems from heat and abrasion.

This material’s resilience and adaptability make it indispensable in automotive manufacturing and metal product assembly engineering. The company manufactures high-quality components that enhance performance with excellent adhesion.

Electronics Industry

Silicone foam is a staple in the electronics industry, serving as an effective insulator and sealant. Its closed-cell structure prevents moisture penetration, ensuring the protection of sensitive electronic components. Furthermore, silicone foam offers superior thermal insulation, which is crucial for managing heat in electronic devices.

Companies like Boyd Corporation lead the way in providing advanced thermal management solutions, incorporating silicone foam to enhance the performance and safety of electronic company products.

Construction and Building

In the construction industry, silicone sealants are vital for sealing joints and preventing water and air penetration. These contractors use sealants extensively in weatherproofing applications, protecting buildings and helping to build resilience against harsh weather conditions in the world.

Silicone foam’s resistance to UV radiation and harsh chemicals makes it an ideal choice for outdoor and industrial applications, ensuring the longevity and efficiency of construction projects.

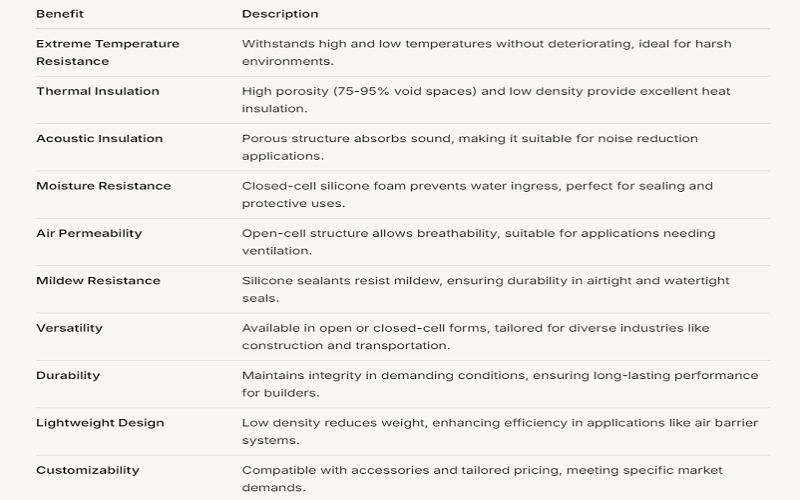

Benefits of Using Silicone Foam

Silicone foam offers numerous benefits that make it a preferred material across various industries. Its outstanding thermal insulation makes it ideal for high-temperature applications, while its low thermal conductivity efficiently maintains building temperatures.

Additionally, silicone foam exhibits excellent compression set resistance, allowing it to maintain its shape and sealing properties over time.

The adaptability of silicone foam extends to glazing applications, ensuring airtight seals around windows and doors, which is crucial for energy efficiency and building integrity. Selecting the appropriate silicone foam can greatly impact a project’s performance and durability, emphasizing the importance of understanding its unique benefits.

Versatility and Adaptability

One of the most remarkable aspects of silicone foam is its versatility and adaptability. It outperforms other materials in extreme conditions, maintaining its integrity and performance over time.

This material’s ability to bond with different materials makes it suitable for a wide range of applications, from electronics to automotive and construction.

American Sealants, Inc. is known for offering a wide selection of silicone foam solutions, focusing on quality and customization to meet various industry needs.

Long Lifespan and Durability

Silicone foam is renowned for its long lifespan and durability, often exceeding 20 years under optimal conditions. Its resilience against extreme temperatures makes it ideal for demanding environments.

Regular inspections and timely repairs are crucial for maintaining the effectiveness of silicone sealants, preventing water intrusion and potential structural damage.

Addressing minor damages promptly can significantly extend the lifespan of silicone foam, ensuring safety and durability.

Safety and Environmental Resistance

Silicone foam is designed to withstand harsh environmental conditions, providing excellent protection for electronic components against moisture, dust, and physical damage.

Its resistance to UV radiation helps prevent degradation over time, ensuring long-term durability.

Additionally, silicone foam’s ability to resist heat enhances safety in various applications, making it a safe and reliable choice for demanding environments.

How to Choose the Right Silicone Foam for Your Project

Choosing the right silicone foam for your project involves a careful assessment of specific requirements, including the purpose, properties, and environmental conditions.

Understanding the manufacturing process is crucial for selecting sealants that align with production needs, such as curing speed and compatibility with substrates. By considering these factors, you can ensure that the silicone foam you choose meets the demands of your next project.

Evaluating different silicone foam formulations can reveal trade-offs in performance characteristics, helping you identify the most suitable option for your applications. In the following subsections, we will discuss the key considerations for selection and how to compare different products effectively.

Considerations for Selection

When selecting silicone foam, it’s essential to consider factors like application requirements, environmental exposure, and the specific characteristics needed for performance. Analyzing the manufacturer’s specifications and certifications ensures the quality and reliability of the products.

Additionally, silicone foam’s ability to bond with various substrates enhances its adhesive application range across multiple industries. Evaluating properties like curing time, adhesion strength, and flexibility helps in making an informed decision about adhesives.

Comparing Products

Comparing silicone foam products involves assessing their structural characteristics, such as cellular foams, sponges, and solid forms. Cellular foams offer excellent conformability and sealing abilities, ideal for applications requiring flexibility and long-term reliability. Closed-cell silicone sponges are known for their toughness and durability, suitable for high-stress environments.

Solid silicones provide a consistent seal without compression, making them perfect for precision applications in aerospace and medical devices. By understanding these differences, you can find the right product to meet your specific needs.

Leading Manufacturers and Suppliers of Silicone Foam

The silicone foam market is dominated by several leading manufacturers known for their innovation and quality products. As of April 2025, the following companies are recognized as top manufacturers in this field:

- American Sealants

- Milliken

- Polycast Industries

- Genesee Polymers Corporation

These companies offer a wide range of silicone foam products tailored to meet the diverse needs of various customers industries.

In the following subsections, we will focus on American Sealants, Inc., a key player in the market, and other notable manufacturers who have made significant contributions to the silicone foam industry.

American Sealants

American Sealants, Inc. stands out as one of the top manufacturers of silicone sealants, offering a range of innovative products designed to meet the diverse needs of various industries.

They specialize in modified silicone sealants, which vary in composition compared to regular silicone sealants, providing tailored solutions for specific applications. It is crucial to understand these differences to avoid confusion during a purchase. This awareness helps ensure the right product is selected for the job.

American Sealants, Inc. excels in providing high-quality, trusted products from traffic coatings to waterproofing and encapsulating, all meeting industry standards, including bonding solutions.

Other Notable Manufacturers

Other key players in the silicone sealant market include Momentive, known for its innovative solutions in various industrial applications. Shin-Etsu Silicones is a leading manufacturer with pioneering advancements in silicone technology across multiple sectors.

Sika offers a comprehensive range of construction materials, including high-performance silicone sealants tailored for building applications. Siltech Corporation, founded in 1989, is recognized for its extensive patent portfolio in silicone technology.

Wacker Chemie AG, a German manufacturer, is known for its range of silicone resins and polymers, with a significant presence in global markets.

Installation and Application Tips

Proper installation of silicone foam can significantly enhance its sealing efficiency and longevity. Regular checks help identify any signs of wear or damage early, ensuring the silicone foam remains effective for a longer period.

Proper storage conditions, such as cooler environments, can also extend the usable life of silicone foam.

In the following subsections, we will discuss preparation and priming techniques and effective application techniques to ensure the best results for your research projects page.

Preparation and Priming

Proper preparation and priming are vital for ensuring a strong bond when applying silicone sealants. Start by cleaning the surfaces thoroughly to remove dirt, oil, and moisture, which can hinder adhesion. For smooth, non-porous surfaces like ceramic and glass, silicone sealants perform best, while untreated wood and some masonry may require priming for optimal results.

Before applying new silicone sealant, it is essential to remove old sealant residues using a softening agent followed by scraping. Using masking tape can help keep the application area clean and ensure straight lines during the silicone sealant application. Always ensure surfaces are dry and work in a well-ventilated area to enhance the effectiveness of the sealant.

Application Techniques

To ensure effective sealing, follow these steps:

- Apply silicone foam to smooth surfaces for an even spread and strong bond.

- Use a caulking gun for precise application, ensuring an even layer of silicone foam.

- Apply silicone foam in a continuous bead without breaks to create a more effective seal.

Masking tapes can help create clean lines and prevent excess silicone from spreading to unwanted areas during application. After application, smoothing the silicone foam with a tool can help create a better seal and improve appearance. Applying steady, controlled pressure with a caulking gun improves accuracy during application.

Maintenance and Longevity

Routine upkeep is essential for maximizing the durability and functionality of silicone foam products. Here are some key maintenance tips:

- Regularly clean surfaces thoroughly to remove dust and grease before application.

- Fully remove old sealant residues before applying new silicone foam to ensure a strong bond.

- Ensure surfaces are thoroughly dry before applying primers to prevent trapping moisture, which can affect adhesion.

By following these steps, you can significantly enhance the lifespan and effectiveness of silicone foam.

We will discuss the importance of regular inspections and the steps for repairing and replacing silicone foam to maintain its performance and longevity.

Regular Inspections

Regular inspections are crucial for ensuring that silicone foam maintains its physical properties over time. Regular inspections, especially after the first 10 years, are recommended for silicone foam. Neglecting regular inspections can lead to undetected degradation of silicone foam’s properties, increasing the risk of failure in applications.

Performing timely inspections helps maximize the longevity and performance of silicone foam, ensuring it meets safety and operational standards.

Repair and Replacement

Understanding when silicone foam has lost its effectiveness is crucial; indicators include visible wear, loss of elasticity, or deterioration in performance. To repair silicone foam, ensure the area is clean and dry, then use a silicone sealant to fill in cracks or damaged areas for effective restoration.

When replacing silicone foam, remove the old foam carefully, clean the surface thoroughly, and apply new silicone foam, ensuring proper adhesion.

Summary

Silicone foam continues to be a game-changer across various industries, offering unparalleled versatility, durability, and safety. Its applications in automotive, electronics, and construction have demonstrated its vital role in enhancing performance and longevity.

By understanding its properties, benefits, and the importance of proper installation and maintenance, you can make informed decisions for your projects.

As technology advances, silicone foam will undoubtedly remain a cornerstone material, driving innovation and reliability. Embrace the potential of silicone foam and let it propel your projects to new heights.

Frequently Asked Questions

What are the primary components of silicone foam?

The primary components of silicone foam include silicone resin, fillers, cross-linking agents, and catalysts, which collectively contribute to its distinctive properties.

How does silicone foam benefit the automotive industry?

Silicone foam greatly benefits the automotive industry by providing effective gaskets that prevent leaks, protecting electrical systems from heat and abrasion, and significantly enhancing the durability of vehicle components. This improved performance contributes to overall vehicle reliability and longevity.

What makes silicone foam suitable for electronic applications?

Silicone foam is suitable for electronic applications due to its closed-cell structure, which prevents moisture penetration and offers excellent thermal insulation, effectively protecting sensitive components from environmental damage.

Why is regular inspection of silicone foam important?

Regular inspections of silicone foam are crucial for maintaining its properties and effectiveness, which helps to prevent potential failures and extend its lifespan. Timely detection of any deterioration allows for proactive measures to be taken.

What steps should be taken to repair or replace silicone foam?

To repair silicone foam, clean the area and fill cracks with silicone sealant. For replacement, remove the old foam, clean the surface, and apply new silicone foam for optimal adhesion.