Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency.

However, one common challenge faced during this process is the occurrence of splay in injection molding.

This article explores the main causes of splay in injection molding and offers practical solutions to effectively prevent and address this cosmetic defect.

What Is Splay In Plastic Injection Molding?

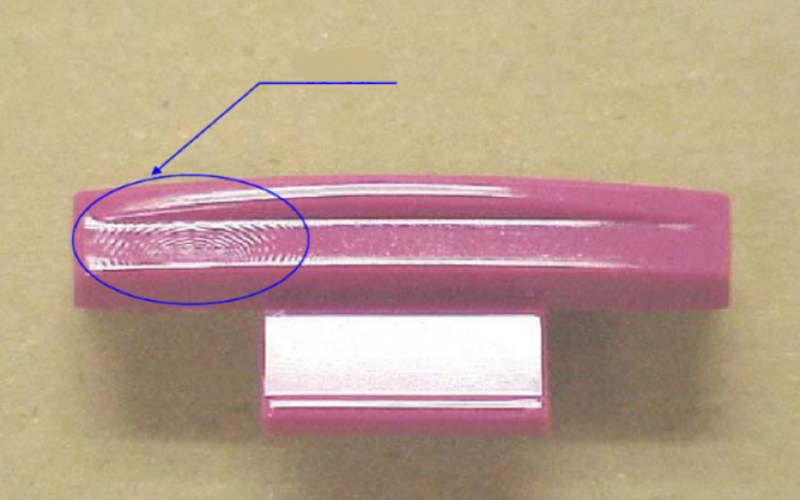

Splay in plastic injection molding is a common cosmetic defect characterized by off-colored streaks or a single silver streak appearing on the plastic surface of molded parts.

These streaks, often referred to as splay marks, result from the presence of tiny gas bubbles or moisture that turns into steam during the molding process.

As molten material fills the mold cavity, trapped gases or moisture create these distinctive water wave patterns, which not only affect the appearance but can also reduce the mechanical strength of the molded part.

Common Causes Of Injection Molding Splay

Splay in injection molding can be triggered by various factors related to materials, process settings, and equipment conditions.

It is important to determine the underlying cause of these visual defects—whether related to the mold, material, process, or machine—to ensure effective troubleshooting and corrective action.

Moisture In Raw Materials

Moisture in raw materials is one of the most common causes of splay in injection molding.

Many plastics, especially hygroscopic materials like polycarbonate and nylon, tend to absorb moisture from the environment. PVC, a heat-sensitive plastic, is particularly prone to splay if not properly dried.

When these plastic particles containing moisture are heated in the injection molding machine’s barrel during the forming cycle, the moisture turns into steam. Overheating moist raw material can further exacerbate splay formation.

This steam forms tiny gas bubbles within the molten material, which travel to the surface of the molded part, creating the characteristic silver streaks or water wave patterns known as moisture related splay.

Improper Material Temperature

Excessive heat can cause burning and material degradation, resulting in visible defects such as discoloration or surface imperfections.

If the barrel temperature is set too high, the melting material can degrade, releasing gases that create unwanted silver streaks on the plastic surface.

Conversely, if the temperature is too low, the material may not melt properly, leading to poor flow and trapped air bubbles that cause splay marks.

Inadequate Mold Temperature

Inadequate mold temperature is a significant contributor to splay in injection molding.

When the mold temperature is too low, the molten material cools rapidly upon contact with the mold cavity surface.

If the mold temperature is too high, melted plastic can quickly block air vents, trapping gases and causing splay. Additionally, shortening the flow channels can help maintain optimal melt flow and reduce the risk of splay caused by rapid cooling.

Insufficient Back Pressure

Insufficient back pressure during the injection molding process can significantly contribute to the occurrence of splay in injection molding.

Back pressure helps ensure thorough melting and mixing of the plastic particles in the barrel, promoting a uniform molten material flow.

When back pressure is too low, the plastic may not be properly plasticized, leading to the entrapment of air and moisture within the melt.

This trapped air forms tiny gas bubbles that manifest as silver streaks or splay marks on the plastic surface.

Poor Degassing

Poor degassing during the injection molding process is another critical factor that can lead to splay in injection molding.

A poorly maintained or improperly designed nozzle can contribute to air entrapment and poor degassing, allowing cold material or air to enter the mold cavity.

These bubbles travel through the mold cavity and create the characteristic silver streaks or off-colored streaking on the plastic surface.

Causes of poor degassing include inadequate venting in the mold, trapped air in the hopper or barrel, and insufficient vacuum or venting systems.

How To Avoid Splay During Injection Molding?

To effectively prevent splay in injection molding and ensure high-quality molded parts, consider the following key measures.

Before starting the molding process, operators should wipe away any excess lubricant or oil from the mold surfaces to maintain proper surface quality and prevent issues caused by over-lubrication.

Thoroughly Dry Raw Materials

Properly drying raw materials is essential to prevent splay in injection molding. Contamination of raw material with moisture or foreign substances can also lead to splay, making it important to handle materials carefully.

Hygroscopic plastics, such as polycarbonate and nylon, have a natural tendency to absorb moisture from the surrounding environment.

To avoid this splay problem, it is crucial to use appropriate drying equipment and follow recommended drying times and temperatures for each type of plastic.

Improve Mold Venting

Improving mold venting and degassing is essential to reduce splay in injection molding.

Proper venting allows trapped gases and air to escape from the mold cavity during the injection process, preventing the formation of tiny gas bubbles that cause silver streaks or off-colored streaking on the plastic surface.

Excess lubricant or debris can block mold vents, reducing venting efficiency and leading to defects. Improving venting and nozzle maintenance can help solve both splay and delamination issues.

Control Injection Speed And Pressure

Controlling injection speed and pressure is vital to preventing splay in injection molding.

Optimizing gate size and position can help control melt flow and reduce the risk of splay by ensuring the material enters the mold efficiently and without air entrapment.

Similarly, maintaining optimal injection pressure ensures that the molten material flows smoothly through the mold cavity without creating voids or air pockets.

Properly balancing injection speed and pressure during the molding cycle helps minimize the risk of splay by promoting uniform flow, reducing shear stress, and preventing premature cooling or degradation of the material.

Conclusion

Splay in injection molding is a common yet preventable cosmetic defect that can significantly impact both the appearance and mechanical strength of plastic parts.

Understanding the root causes—such as moisture in raw materials, improper material and mold temperatures, insufficient back pressure, poor degassing, mold leaks, and issues like flow lines or blocked vents—is crucial for effective prevention.

Implementing these solutions can effectively fix splay and related defects in injection molding.

Applying these best practices not only enhances product quality but also improves production efficiency, ultimately leading to higher customer satisfaction and reduced manufacturing costs.