Structural foam is a material known for being lightweight yet strong, commonly used in industries ranging from automotive to construction.

Produced via a low-pressure injection molding process, it involves mixing nitrogen gas with molten polymer to create a foam with a solid outer layer and a cellular core.

This article will delve into what structural foam is, how it’s made, and why it’s a preferred choice across various applications.

What is Structural Foam Molding?

Structural foam molding is a low-pressure injection molding process that ingeniously combines nitrogen gas with molten polymer to create a molded article.

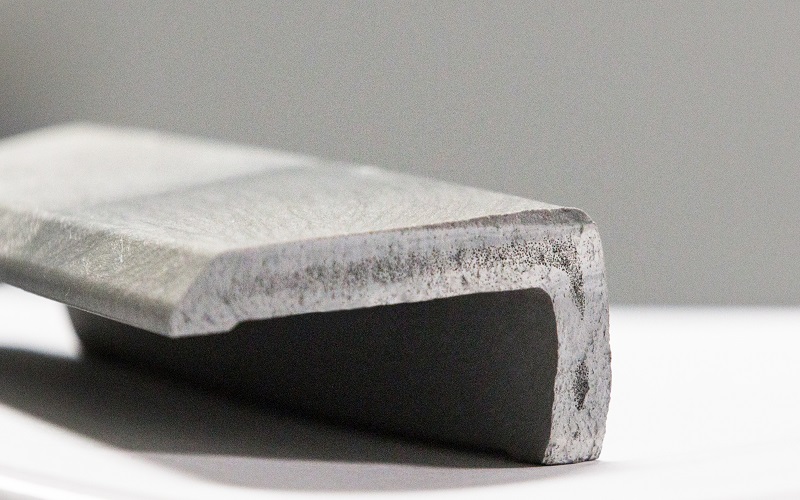

Unlike traditional injection molding, this process involves the foaming plastic touching the cold walls of the mold, resulting in a solid outer layer with a honeycomb interior.

This unique structure not only enhances the durability of the final product but also offers significant weight reduction through foam injection structural foam injection molding.

The wall thickness in structural foam molding can vary considerably, typically ranging from 0.200 inches to 0.500 inches.

This flexibility in wall thickness and mold medium wall thickness allows for the creation of parts that are both robust and lightweight, making it an ideal choice for a wide range of applications.

Key Characteristics of Structural Foam Molded Parts

One of the standout features of structural foam molded part includes:

- High moldability coupled with impressive resistance to deformation, making them suitable for applications where durability and precision are paramount.

- Being more lightweight compared to traditional injection molded products, achieving density reductions of 10-30%.

- Significant weight reduction without compromising strength, making structural foam parts highly efficient and versatile.

The benefits of thicker wall sections in structural foam molded parts are noteworthy.

These thicker sections allow for rapid and low-pressure filling during the molding process, which can help optimize filling.

This not only speeds up production but also reduces the internal stresses within the material, enhancing the overall structural integrity of the parts, including plastic structural elements with two solid wall sections.

Structural foam is often used in consumer products like surfboards and kayaks due to its shock absorption and lightweight properties.

The Structural Foam Molding Process Explained

The structural foam molding process involves the following steps:

- Introducing a chemical blowing agent or nitrogen gas into molten polymer.

- Injecting this mixture into a mold under low pressure.

- Allowing the gas to expand, forming a foam that creates a cellular or honeycomb structure within the inner core of the part.

- Utilizing low-pressure injection to minimize internal stresses and reduce the likelihood of defects. The structural foam process is essential for achieving these results.

What sets this process apart is the cellular internal core sandwiched between two solid outer layers, minimizing internal shrinkage during molding.

This structure not only provides excellent strength-to-weight ratios but also allows for the creation of complex and intricate designs, captured with the same molded in detail.

The result is a part that combines lightweight properties with robust structural integrity, making it ideal for various demanding applications.

Additionally, the cellular core enhances the overall performance of the design.

Low Pressure Process Benefits

One of the most compelling benefits of the low-pressure process in structural foam molding is the significant cost savings it offers, including:

- Lower durability requirements for tooling for larger parts, which translate to lower material costs

- Shorter production cycles

- Reduced logistics expenses

This molding technique is particularly well-suited for producing large parts that require high-quality finishes while being lightweight and structurally sound.

The ability to run multiple points simultaneously also allows for significant savings in cost and lead times, making structural foam molding a highly moldable and cost-effective option for manufacturers.

Importance of Wall Thickness Control

Controlling wall thickness during the structural foam molding process is essential for optimizing the properties of the final product.

Structural foam parts can be designed with varying wall thicknesses, which enhances their structural integrity and performance.

This combination of a lightweight inner core with a rigid outer layer results in parts that are both strong and lightweight.

By carefully controlling medium wall thickness and ensuring dimensional stability, manufacturers can optimize process repeatability, the mechanical properties, very thick wall sections, thick wall sections, and weight of the final product, ensuring it meets the required specifications and performance standards.

Role of Blowing Agents

Blowing agents play a crucial role in the structural foam molding process. Their functions include:

- Creating a cell structure that compensates for shrinkage and enhances part integrity.

- Being injected as gas into the mold.

- A blowing agent expands once released.

- Undergoing a chemical reaction to create foam.

This foaming action is critical for achieving the desired cellular structure within the part.

The choice of blowing agents can significantly influence the quality and characteristics of a solid plastic part in structural foam molded plastic part.

For example, plastic cells collapse or freeze upon contact with mold walls, forming the rigid and smooth outer skin in structural foam molding, which can create internal pressure.

This microcellular structure in the resin leads to reduced weight without compromising strength, making the final product both highly resistant and lightweight parts, and durable.

Advantages of Structural Foam Molding

Structural foam molding offers numerous advantages over traditional manufacturing methods.

It is more cost-effective for producing large parts with heavy cross sections, thanks to the low-pressure process that ensures molds are completely filled while minimizing raw material usage and reducing production costs.

This cost efficiency extends to a diverse range of applications, from automotive components to insulation and packaging, due to the lightweight and durable nature of structural foam with minimal sink marks.

The benefits of structural foam are widely recognized across various sectors, including automotive, construction, and consumer products.

Whether it’s improving fuel efficiency in vehicles or providing enhanced strength in construction materials, structural foam molding is a versatile and efficient solution.

Cost Efficiency

The cost efficiency of structural foam molding is one of its most attractive features.

The low-pressure process minimizes raw material usage, leading to significant production cost savings.

Additionally, lower-cost materials and shorter cycle times for larger or thicker parts further contribute to overall production savings.

Structural foam molding can result in substantial reductions in logistics costs and reduces sinks. This method offers an efficient approach to manage expenses in transportation and handling.

The tooling required for this process is less expensive due to the lower durability requirements, making it a cost-effective option for manufacturers looking to optimize their production processes.

Enhanced Product Durability

Products made from structural foam offer high resistance to impact and bending, greatly enhancing their durability.

The mechanical properties of the selected materials directly impact the performance and durability of the final product, making material selection a critical factor.

The cellular structure, along with the solid outer skin, contributes to the integrity of the material. This combination also enhances its superior strength and stiffness properties.

These molded products also exhibit excellent thermal and sound insulation properties, making them advantageous for specific applications where such characteristics are crucial.

Design Flexibility

Structural foam molding offers significant design flexibility, enabling manufacturers to:

- Create intricate shapes that are often unattainable with traditional methods

- Produce complex shapes and designs

- Incorporate multiple tooling options in production

The result is products that are lighter yet more durable compared to those manufactured through traditional standard injection molding methods, including aluminum tooling.

This flexibility in design allows for more innovative and efficient product development, meeting the diverse needs of different industries.

Applications of Structural Foam Products

Structural foam products are increasingly utilized across various industries, improving performance and reducing costs.

The automotive industry, for example, extensively uses structural foam for components that contribute to weight reduction and improved fuel efficiency.

In construction and infrastructure, structural foam materials provide enhanced strength and longevity for materials, making it an ideal choice for various applications.

Everyday consumer goods also widely incorporate structural foam, allowing for improved performance and reduced manufacturing costs.

Automotive Industry

Weight reduction is crucial in the automotive industry as it enhances vehicle performance and fuel economy.

Structural foam molding allows for the production of lighter automotive parts without sacrificing strength.

Incorporating lighter materials through structural foam allows vehicles to achieve better fuel efficiency due to reduced energy requirements for propulsion.

Overall, the integration of structural foam in automotive manufacturing supports the industry’s push towards sustainability through improved fuel efficiency and reduced emissions.

This makes structural foam a valuable asset in the quest for more environmentally friendly and efficient vehicles.

Construction and Infrastructure

Structural foam blocks are ideal for projects like parking structures, as they alleviate stress on underground buildings and allow for innovative landscaping solutions.

These foam blocks also help mitigate issues caused by soft soil in highway construction, preventing frost heave and ensuring stable road surfaces.

The enhanced strength and longevity provided by structural foam make it a valuable material in construction applications where durability is crucial.

The use of structural foam in construction not only improves the durability and longevity of the materials but also contributes to cost savings and efficiency in the building process.

Consumer Goods

Structural foam molding provides multiple advantages over traditional material processes, making it highly applicable for consumer goods.

One of the major benefits is cost efficiency, as it reduces raw material costs and overall production expenses. This makes structural foam an attractive option for manufacturers looking to produce high-quality consumer goods at a lower cost.

The durability of structural foam products is enhanced, offering resistance to impact and thermal expansion, which is essential for everyday consumer items.

Additionally, the design flexibility of structural foam molding enables the creation of complex shapes and varied product designs.

This versatility makes structural foam products integral to a broad range of applications in the consumer goods sector.

Choosing the Right Materials for Structural Foam Molding

Selecting the right materials for structural foam molding is crucial to ensure the performance, cost-effectiveness, and sustainability of the final product.

Common thermoplastics used in structural foam molding include:

- HDPE

- Polypropylene

- ABS

- Styrene

Each offers unique properties that make them suitable for different applications. The choice of material can significantly impact the mechanical properties, strength, and insulation capabilities of the final product.

Factors like mechanical properties, cost, and environmental impact are essential when selecting materials for structural foam molding.

Understanding these factors helps manufacturers optimize their material choices for better product outcomes.

By carefully considering these aspects, manufacturers can ensure that their structural foam products meet the required standards and performance expectations.

Common Thermoplastics Used

Common thermoplastics used in structural foam molding include HDPE, polypropylene, ABS, and styrene.

Polyethylene and polypropylene are two widely used thermoplastics in structural foam molding due to their unique properties.

These materials offer a high strength-to-weight ratio and durability, making them suitable for a wide range of applications.

Mechanical properties, such as strength and insulation capabilities, significantly influence material selection for structural foam applications.

Factors like mechanical properties, cost, and environmental impact are essential when selecting materials for structural foam molding.

By understanding these factors, manufacturers can make informed decisions that enhance the performance and cost-effectiveness of their products.

Factors to Consider

Cost considerations can significantly influence the choice of raw materials, making budget constraints a critical factor in material selection.

The environmental impact of materials is increasingly important, with many manufacturers seeking sustainable options.

By selecting appropriate materials, manufacturers can ensure the performance, cost-effectiveness, and sustainability of structural foam products.

Understanding these factors helps manufacturers optimize their material choices for better product outcomes.

By carefully considering cost, environmental impact, and material properties, manufacturers can create structural foam products that meet the required standards and performance expectations, while also being economically viable and environmentally friendly.

Summary

In summary, structural foam molding is a versatile and cost-effective manufacturing process that offers numerous benefits over traditional methods.

From the automotive industry to construction and consumer goods, structural foam products are widely utilized due to their lightweight, durable, and flexible nature.

The ability to create complex shapes and designs, coupled with the cost efficiency and enhanced product durability, makes structural foam molding an attractive option for various applications.

By understanding the basics of structural foam molding, its process, and the factors to consider when choosing materials, you can make informed decisions that enhance the performance and cost-effectiveness of your products.