Thermoplastic polyurethane (TPU) is a highly versatile polymer material celebrated for its many applications across industries like medical, automotive, and consumer goods.

As a thermoplastic elastomer, TPU offers excellent abrasion resistance, chemical resistance, high elasticity, and durability without relying on cross links, unlike most polyurethanes.

This Essential Guide explores the composition, mechanical properties, manufacturing processes, and key applications of thermoplastic polyurethane TPU, highlighting why it is the right material for specific applications requiring flexibility and performance.

Composition of Thermoplastic Polyurethane

Understanding the structure of thermoplastic polyurethane TPU is crucial to appreciating its distinct properties and many applications.

Unlike other polymers such as polyethylene or PVC, TPU combines elasticity with durability, making it suitable for different applications.

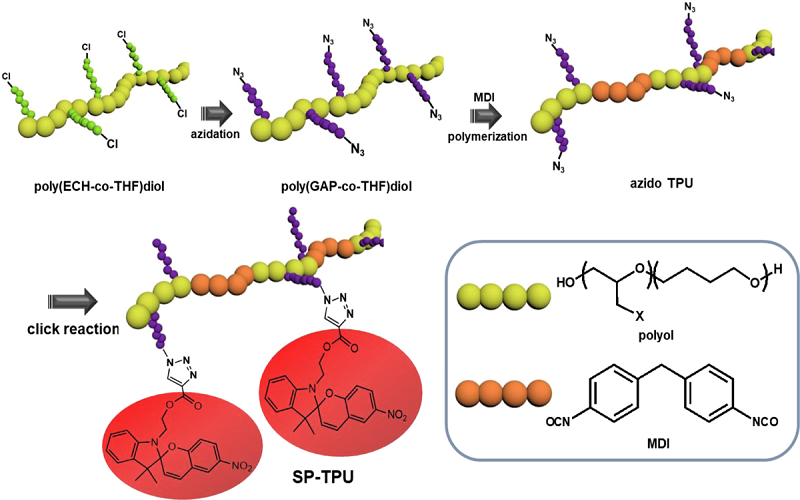

Structure and Chemistry of TPU

Thermoplastic polyurethane is a block copolymer formed by alternating sequences of hard segments and soft segments. The hard segments provide tensile strength and structural integrity, while the soft segments contribute to high elasticity and low temperature flexibility.

Unlike most polyurethanes, which form cross links through a chemical reaction to create rigid structures, TPU remains a thermoplastic that can be heated and reshaped, ideal for injection molding and extrusion.

This polymer’s physical properties make it a standout among thermoplastic materials, offering good resistance to wear and environmental factors.

Polyester-Based vs. Polyether-Based TPUs

The main types of TPU—polyester-based TPUs and polyether-based TPUs—exhibit key differences in their properties.

Polyester-based TPUs provide excellent abrasion resistance and chemical resistance to oils and solvents, making them suitable for industrial applications like coatings, sealants, and automotive parts.

Polyether-based TPUs excel in hydrolysis resistance and low temperature performance, ideal for medical applications such as medical tubing or medical devices.

These distinct properties allow manufacturers to choose the right material for specific applications, ensuring performance and durability.

Comparison with Other Polymers

Compared to other polymers like polyethylene or rubber, TPU offers unique advantages.

Its elastic nature surpasses plastic rigidity, while its resistance to chemicals and abrasion outperforms rubber in durability.

The absence of permanent cross links in TPU enhances its processability, setting it apart from most polyurethanes and making it a preferred material for many applications across industries.

Benefits of Thermoplastic Polyurethane

The thermoplastic polyurethane TPU’s mechanical properties make it an excellent choice for industries seeking durable, flexible, and resistant materials. Its advantages drive its widespread use in different applications.

Abrasion and Chemical Resistance

TPU’s excellent abrasion resistance allows it to withstand wear in demanding environments, such as automotive wheels, footwear soles, or industrial coatings.

Its chemical resistance to oils, solvents, and other chemical substances ensures durability in industrial applications.

Polyether-based TPUs offer hydrolysis resistance, making them resistant to moisture and ideal for medical devices like medical tubing, where structural integrity is critical.

High Elasticity and Impact Resistance

The high elasticity of TPU, driven by its soft segments, enables significant elongation without breaking, making it ideal for flexible products like phone cases or elastic components.

Its impact resistance ensures performance in high-stress environments, such as automotive parts or consumer goods.

Polyether-based TPUs maintain elasticity at low temperatures, enhancing versatility for outdoor or medical applications.

Processability and Customization

As a thermoplastic elastomer, TPU can be heated, injection molded, or extruded, making it compatible with manufacturing processes for components like medical tubing or automotive wheels.

Manufacturers can adjust the ratio of hard and soft segments to customize physical properties, such as tensile strength or elasticity.

Additives can further enhance chemical resistance, impact resistance, or aesthetic appeal, ensuring TPU meets specific applications in industries like footwear or consumer goods.

Manufacturing Processes for TPU

The manufacturing of thermoplastic polyurethane involves advanced processes to achieve its distinct properties. These processes are essential for producing high-quality components for many applications.

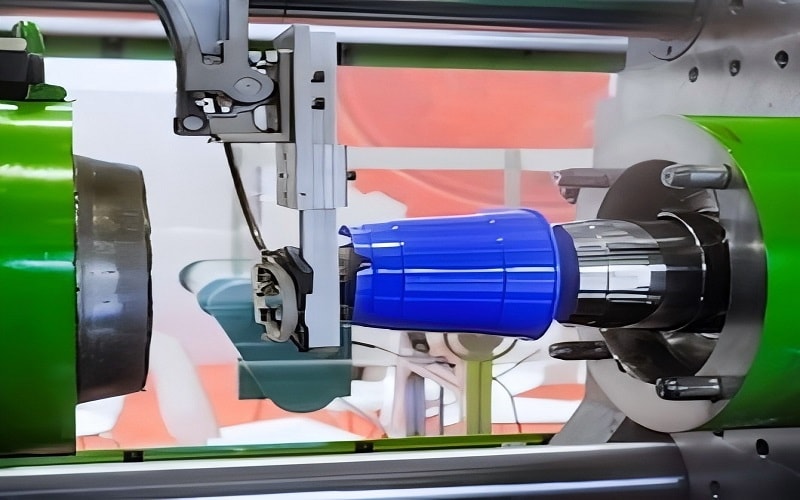

Injection Molding and Extrusion Techniques

TPU is frequently injection molded or extruded to create products like medical tubing, phone cases, or automotive parts.

In injection molding, TPU resin is heated to a molten state and injected into a mold to form precise components.

Extrusion produces continuous films, tubes, or coatings, used in medical or industrial applications.

The thermoplastic nature of TPU, free of permanent cross links, allows efficient reshaping, ensuring durability and performance in final products.

Tailoring TPU for Specific Needs

Manufacturers can customize TPU by adjusting the ratio of hard and soft segments to enhance mechanical properties like tensile strength, abrasion resistance, or elasticity.

For example, polyester-based TPUs are optimized for industrial applications requiring good resistance to oils and solvents, while polyether-based TPUs are tailored for medical applications with hydrolysis resistance.

Additives like UV stabilizers or colorants further improve performance, making TPU suitable for specific applications across industries.

Key Applications of Thermoplastic Polyurethane

The versatility of thermoplastic polyurethane TPU enables its use in many applications, from medical devices to automotive parts and consumer goods. Its distinct properties make it a preferred material for different applications.

Medical Applications

Polyether-based TPUs are commonly used in medical devices such as medical tubing, catheters, and wound dressings due to their hydrolysis resistance and biocompatibility.

The low temperature flexibility and high elasticity of TPU ensure performance in sterile or cold environments, while its chemical resistance protects against solvents used in medical settings.

These properties make TPU an excellent choice for medical applications requiring durability and safety.

Automotive and Industrial Applications

In the automotive industry, polyester-based TPUs are used for coatings, sealants, and components like wheels, dashboards, or interior panels, leveraging their excellent abrasion resistance and impact resistance.

TPU’s ability to withstand oils, solvents, and chemicals makes it suitable for industrial applications, such as conveyor belts or protective coatings.

Its durability ensures long-lasting performance in these high-demand environments.

Consumer Goods and Footwear

TPU is a popular choice for consumer goods like phone cases, sports equipment, and footwear soles due to its high elasticity and abrasion resistance.

The flexible nature of TPU allows it to form elastic components that withstand daily wear, while its versatility supports customization in colors or textures.

In footwear, TPU provides a balance of rubber-like elasticity and plastic-like durability, making it ideal for athletic shoes or work boots across many applications.

Challenges in Using Thermoplastic Polyurethane

While thermoplastic polyurethane TPU offers numerous advantages, manufacturers must address challenges to ensure optimal performance.

These considerations are critical for selecting the right material for specific applications.

Material Selection and Compatibility

Choosing between polyester-based TPUs and polyether-based TPUs requires understanding their key differences.

Polyester-based TPUs offer good resistance to oils and solvents but may be less resistant to moisture, while polyether-based TPUs excel in hydrolysis resistance and low temperature performance.

Selecting the wrong type can lead to material degradation, affecting mechanical properties like tensile strength or elasticity.

Compatibility with other polymers or materials during coating or lamination processes is also essential to maintain structural integrity.

Processing and Cost Challenges

The manufacturing process for TPU, such as injection molding or extrusion, requires precise control of temperature and pressure to avoid defects.

Higher temperatures can cause degradation, reducing abrasion resistance or chemical resistance.

TPU production can be more costly than other polymers like polyethylene due to the complexity of polyurethane polymers.

Companies must invest time in optimizing processes and maintaining adequate stock to meet customer demand for high-quality products in industries like medical or automotive.

Conclusion

Thermoplastic polyurethane (TPU) is a versatile polymer material that excels in many applications due to its excellent abrasion resistance, chemical resistance, high elasticity, and lack of permanent cross links.

Its block copolymer structure, with hard and soft segments, enables customization of mechanical properties to meet the needs of industries like medical, automotive, and consumer goods.

From medical tubing to footwear soles and automotive coatings, TPU delivers durability and performance that surpass other polymers like polyethylene or PVC.

By understanding the manufacturing process, advantages, and challenges of thermoplastic polyurethane TPU, companies can develop products that withstand demanding conditions and satisfy customer needs.

For more information or to request customized TPU solutions, contact a trusted supplier today to experience the benefits of this remarkable material.