Thermoplastic materials are crucial in modern manufacturing due to their ability to be remelted and reshaped multiple times.

This flexibility makes them highly recyclable and adaptable for numerous applications.

In this article, we delve into the types of thermoplastic materials, their distinct properties, and their widespread uses across various industries.

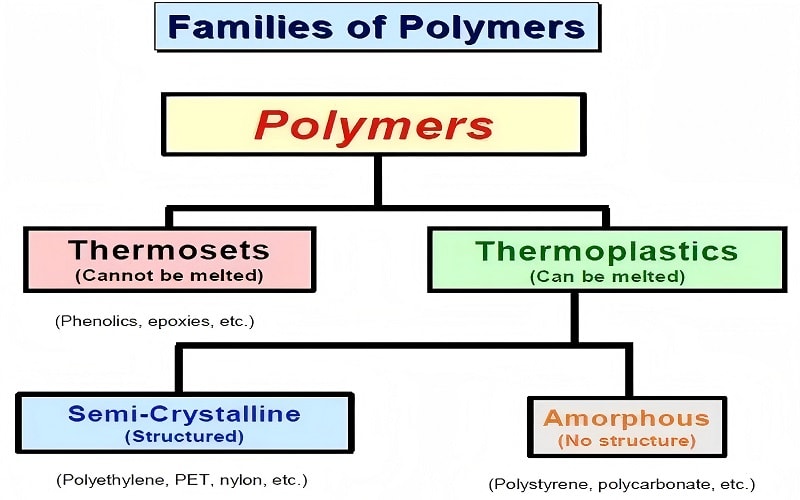

Understanding Thermoplastic Polymers

Thermoplastic polymers, a type of plastic material, become moldable when heated above their glass transition temperature and solidify upon cooling.

Unlike thermosetting polymers, which undergo a curing process to form permanent chemical bonds, thermoplastics can be melted and reformed multiple times without significant degradation, making them highly versatile and recyclable.

The use of thermoplastic material enhances their adaptability in various applications, as thermoplastics harden upon cooling.

Thermoplastics are known for their toughness, flexibility, and non-stick characteristics, contributing to their widespread use in most thermoplastic applications and a wide range of industries.

Amorphous vs. Semi-crystalline Structures

Thermoplastic polymers fall into two categories: amorphous and semi-crystalline.

Amorphous thermoplastics, such as polyvinyl chloride, soften and become rubbery with increasing temperature, lacking a distinct melting point, which is influenced by the arrangement of polymer chains.

Semi-crystalline thermoplastics, like polyethylene terephthalate, have organized crystalline regions known as spherulites, allowing them to melt at specific temperatures.

This crystalline structure influences their mechanical properties and processing behavior.

Chemical Properties

Thermoplastics exhibit strong chemical resistance, making them ideal for the chemical industry and other corrosive environments where they withstand chemical attack.

Polyvinylidene fluoride (PVDF) and Polyethersulfone (PESU) are prime examples, as they resist a wide range of aggressive chemicals, including acids, alkalis, and oils, while maintaining good dimensional stability.

Their chemical stability, combined with manageable resin viscosity during processing, ensures longevity and reliability across various applications.

Mechanical Properties

Thermoplastics’ good abrasion resistance and mechanical toughness make them suitable for high-stress applications, such as heat-resistant medical equipment.

They exhibit excellent dimensional stability and can withstand significant wear and tear, enhancing performance in demanding applications.

Additionally, many thermoplastics resist corrosion from mineral and organic acids, maintaining their integrity when exposed to harsh chemicals.

When heated above their glass transition temperature, thermoplastics transform into a viscous liquid, allowing them to be molded and reshaped for versatile applications.

Popular Types of Thermoplastics

Thermoplastics come in various types, each with unique properties and applications. Common examples include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polyethylene terephthalate (PET)

- Acrylonitrile butadiene styrene (ABS)

Some thermoplastics are crystalline, such as PE and PP, while others are amorphous, like PVC and ABS.

These materials are crucial in industries ranging from packaging film and construction to automotive and medical applications.

Polyethylene (PE)

Polyethylene is a versatile thermoplastic available in forms such as high density polyethylene (HDPE), low density polyethylene (LDPE), and linear low density polyethylene.

HDPE is commonly used for chemical tanks, gas and water pipes, and containers due to its durability and chemical resistance.

LDPE is used for squeeze bottles, sacks, and sheets due to its flexibility and moisture resistance. Polyethylene’s broad range of applications highlights its importance in everyday life.

Polypropylene (PP)

Polypropylene ranks as the second most popular commodity polymer, recognized for its versatility and recyclability.

It is extensively used in medical applications, such as syringes and heat-resistant equipment, as well as in packaging materials for food and chemicals.

Its recyclability (plastic number 5) further enhances its appeal in various industries.

Polyvinyl Chloride (PVC)

Polyvinyl chloride is a durable and versatile thermoplastic used in construction for roofing sheets and electrical insulation, including cable insulation. Its rigidity and chemical resistance make it suitable for various industrial applications, and it serves as a good electrical insulator.

PVC’s widespread use in the construction industry highlights its role in creating long-lasting and reliable infrastructure.

Poly(ethylene terephthalate) (PET)

Poly(ethylene terephthalate) is known for its superior mechanical and thermal properties, excellent chemical resistance, and dimensional stability.

It is widely used in manufacturing liquid containers, food containers, and clothing, making it the most recycled polymer globally.

PET’s recyclability and broad application spectrum highlight its environmental and industrial importance.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is known for its mechanical toughness and impact resistance, making it ideal for smoke detector housings and automotive parts. Its robustness ensures that ABS products can withstand significant physical stress without compromising performance.

Advanced Thermoplastic Materials

In advanced thermoplastics, materials like Polybenzimidazole (PBI) exhibit exceptional chemical and thermal stability, stiffness, and toughness.

These materials are used in high-performance applications such as firefighting clothing, space suits, and protective equipment, demonstrating their crucial role in demanding environments.

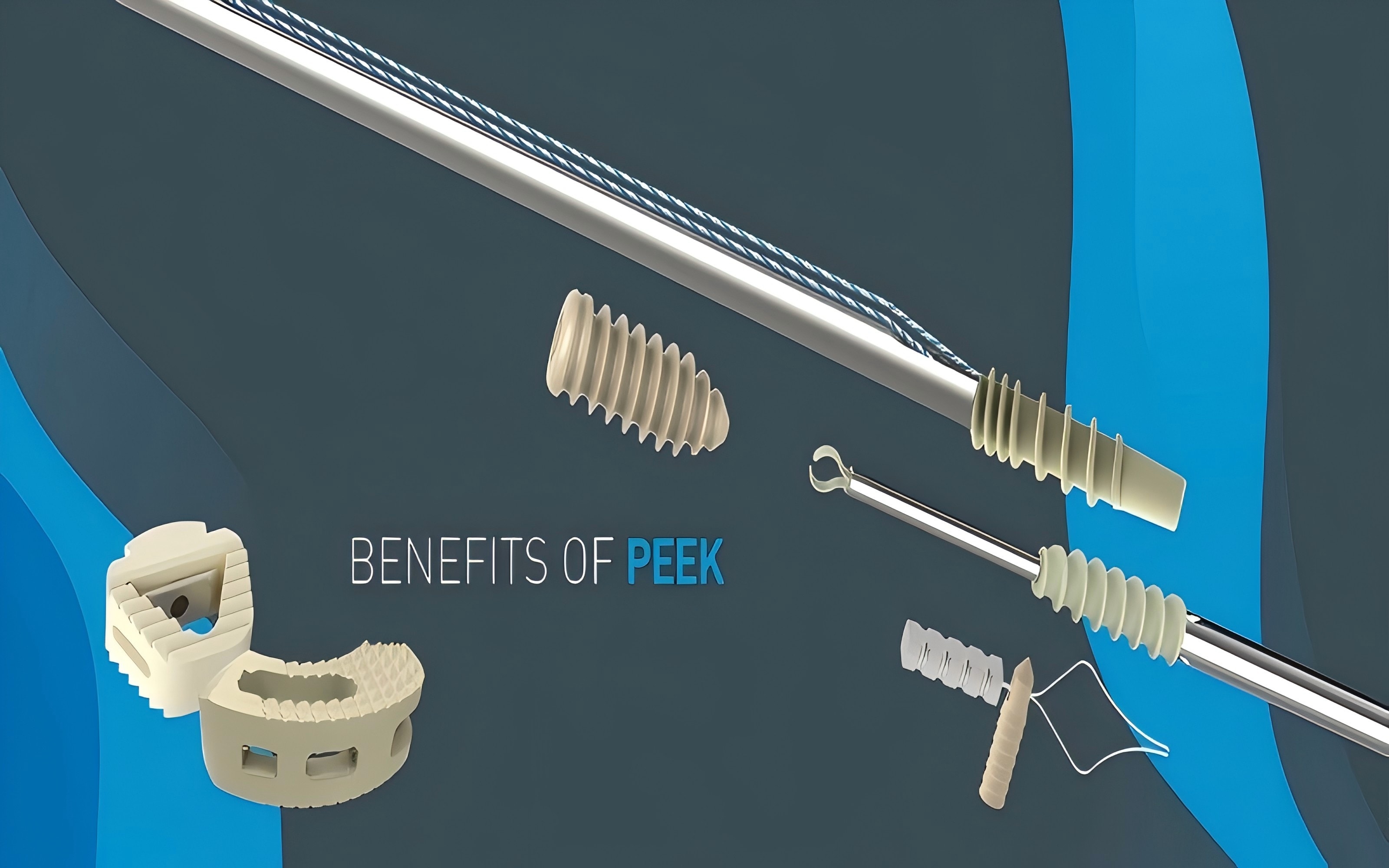

Polyether Ether Ketone (PEEK)

Polyether ether ketone (PEEK) is recognized for its excellent abrasion resistance and low flammability, making it suitable for high-performance applications like medical implants and aerospace components.

PEEK’s ability to maintain structural integrity at high temperatures makes it indispensable in sectors requiring high reliability under extreme conditions.

Polyphenylene Sulfide (PPS)

Polyphenylene sulfide (PPS) is valued for its chemical resistance and excellent electrical properties, making it ideal for environments with aggressive chemicals and high purity liquids.

This unique combination of properties ensures its effectiveness in applications demanding both chemical stability and electrical components.

Polycarbonate (PC)

Polycarbonate is a versatile thermoplastic known by several brand names like Lexan and Makrolon. It is used in applications including:

- safety glasses

- bullet-resistant glass

- CDs and DVDs

- car headlamp lenses

- safety helmets

Its impact resistance and clarity make it suitable for applications requiring both durability and transparency.

Thermoplastic Composites

Thermoplastic composites are made from a thermoplastic matrix combined with reinforcing fibers. Popular thermoplastics in composites include:

- polyethylene

- polypropylene

- polyvinyl chloride

- acrylonitrile butadiene styrene

Advanced thermoplastic composites use materials like polyetherimide and polyether ether ketone, offering improved damage tolerance and remoldability.

Benefits of Thermoplastic Composites

Thermoplastic composites exhibit superior impact strength and damage tolerance, making them suitable for harsh environments.

Unlike thermoset composites, they can be melted and reshaped multiple times, allowing for easy repair and recycling.

This combination of properties makes them appealing to various industries.

Applications of Thermoplastic Composites

Thermoplastic composites are widely used in aerospace, automotive, and construction industries due to their strength and lightweight properties, as well as in specialized applications like fuel cells, bone cement, and food packaging.

Acrylonitrile Butadiene Styrene (ABS), for example, is frequently used to manufacture moving machine parts, sports equipment, and automobile components.

Their high strength-to-weight ratio and impact resistance, driven by the flexibility of amorphous chain segments in their molecular structure, make them ideal for demanding applications.

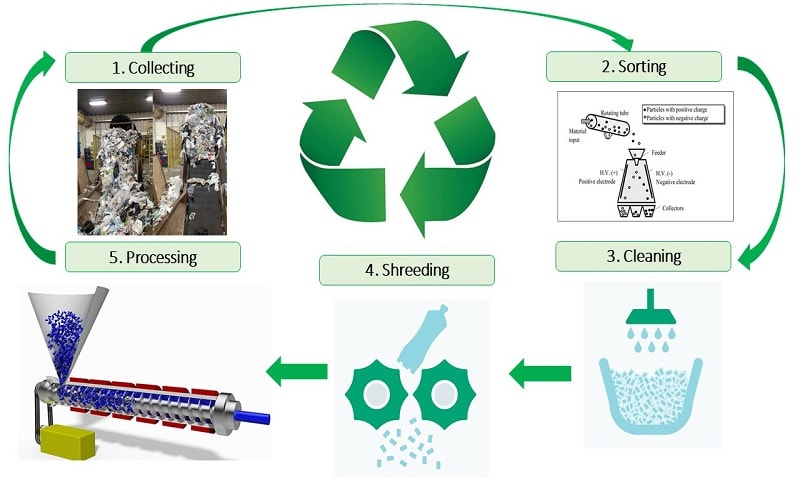

Processing and Recycling

Processing methods for thermoplastics include:

- Extrusion

- Injection molding

- Thermoforming

- Blow molding

Injection molding, in particular, allows for high-volume production with minimal waste, making it a primary method for shaping these materials.

The recyclability of thermoplastics conserves resources and requires less energy compared to producing new plastic, thereby lowering carbon emissions.

Injection Molding

Injection molding is a key method for processing thermoplastics, known for creating precise and complex shapes with high efficiency.

The process involves injecting molten plastic into a mold, where it cools and solidifies, allowing for rapid production cycles and minimal waste.

This method is widely used to manufacture items like power tool casings and medical implants.

Recycling Processes

Thermoplastics are highly recyclable, enabling reuse and repurposing in various applications.

Their chemical resistance allows them to retain physical properties during multiple recycling processes, making them a sustainable choice.

Poly(ethylene terephthalate) (PET) is the most recycled polymer worldwide, highlighting its significant role in recycling efforts.

Thermoplastics in High-Temperature Environments

High-performance thermoplastics like PEEK can withstand temperatures as high as 343°C, making them suitable for extreme thermal conditions.

However, some thermoplastics are limited by their susceptibility to creep under long-term stress and low melting points, restricting their effectiveness in high-temperature applications.

Heat Resistant Thermoplastics

Polyetheretherketone (PEEK) and Polyphenylene Sulfide (PPS), along with polystyrene copolymers, maintain integrity and performance under elevated processing temperatures.

PEEK, for instance, can endure continuous temperatures of up to 482°F (250°C) without significant degradation, making it ideal for high-temperature applications.

PPS offers excellent wear resistance with a relatively low melting point of around 536°F (280°C), allowing it to be processed efficiently while retaining durability in demanding environments.

Applications in High-Temperature Settings

Thermoplastics with exceptional thermal and dimensional stability and a high heat distortion temperature are used in high-temperature settings.

These include aerospace, automotive, and industrial applications where materials must withstand extreme temperatures while maintaining structural integrity.

Safety and Environmental Impact

Safety and environmental considerations are crucial when dealing with thermoplastics.

Some, like PEEK, are known for their low flammability and minimal smoke and toxic gas emission, making them suitable for high-performance applications where safety is paramount.

Toxic Gases and Safe Handling

Certain thermoplastics, including those with amorphous regions like polyvinyl chloride (PVC) and nylon fibres, can emit toxic gases such as hydrogen chloride when burned, requiring careful handling during processing to ensure corrosion protection for equipment and safety for workers.

These emissions pose health risks, making proper ventilation and fume extraction systems essential for the safe handling and processing of these materials.

Sustainability and Biodegradability

Thermoplastics can be recycled repeatedly without losing quality, contributing to sustainability.

Compostable thermoplastic, like poly(lactic acid), is designed to break down quickly in composting conditions, reducing its long-term environmental impact.

The use of renewable resources in thermoplastic production, such as poly(lactic acid), further enhances sustainability.

Summary

Thermoplastics are an integral part of modern material science, offering versatility, durability, and recyclability.

From common types like polyethylene and polypropylene to advanced materials like PEEK and PPS, thermoplastics are used in a myriad of applications across industries.

Their ability to be remolded and recycled, combined with their impressive mechanical and chemical properties, makes them an attractive choice for various applications, including high-temperature environments.

As we continue to innovate and develop new thermoplastic materials, their role in creating sustainable and efficient solutions will only expand.

Frequently Asked Questions

What are thermoplastic polymers?

Thermoplastic polymers are materials that become pliable when heated and harden upon cooling, allowing for repeated molding and shaping. This property makes them highly versatile for various applications in manufacturing and product design.

What is the difference between amorphous and semi-crystalline thermoplastics?

The key difference between amorphous and semi-crystalline thermoplastics lies in their structural properties; amorphous thermoplastics become softer and more pliable with heat, whereas semi-crystalline thermoplastics possess defined crystalline regions that cause them to melt at specific temperatures.

What are the benefits of using thermoplastic composites?

Thermoplastic composites provide enhanced impact strength, improved damage tolerance, and are recyclable, which makes them highly versatile for various applications. These benefits ensure they meet the demands of modern engineering and environmental considerations effectively.

How are thermoplastics processed?

Thermoplastics are primarily processed through methods such as extrusion, injection molding, thermoforming, and blow molding. Each technique allows for versatile applications in manufacturing.

Are thermoplastics recyclable?

Yes, thermoplastics are recyclable and can be processed multiple times without degrading in quality, thereby promoting sustainability.