Improving TPE adhesion is essential for durable products that use these versatile materials. This guide covers techniques to enhance TPE adhesion to various substrates, such as metals and plastics, through proper surface preparation and advanced bonding methods.

Understanding TPE Adhesion

Thermoplastic elastomers (TPEs) are a class of materials that combine the properties of plastics and rubber, offering both flexibility and recyclability. Common types of TPEs include:

- TPVs

- TPUs

- TPR

- S-TPEs Each type is designed for specific applications. The versatility of TPEs allows for:

- Extensive design freedom

- Customization options

- Vibrant color choices These features make them ideal for various products. Additionally, their cost-effectiveness, especially in high-volume injection molding, has made them a popular choice in the manufacturing industry. Thermoplastic vulcanizates are also a significant category within TPEs. Thermoplastics are increasingly being recognized for their potential in various applications.

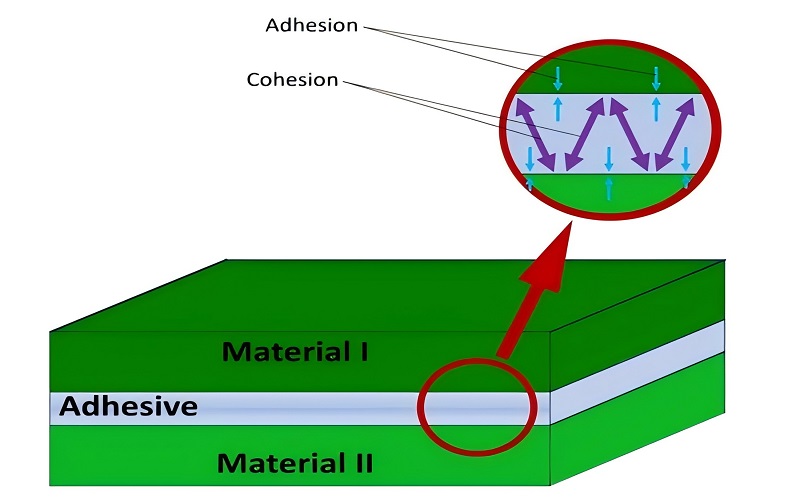

The adhesion of TPEs (thermoplastic elastomers) to other materials, such as thermoplastic rubber and natural rubber, is a critical factor in determining the durability and performance of the final product.

TPEs’ ability to bond with various substrates, such as engineering plastics, metals, thermoplastic rubber, and natural rubber, depends on several factors, including the chemical compatibility of the materials and the surface energy of the substrates.

Recognizing these factors helps in improving TPE adhesion, ensuring TPE-based products, including those incorporating thermoplastic rubber and natural rubber, meet performance standards.

Key Factors Affecting Adhesion

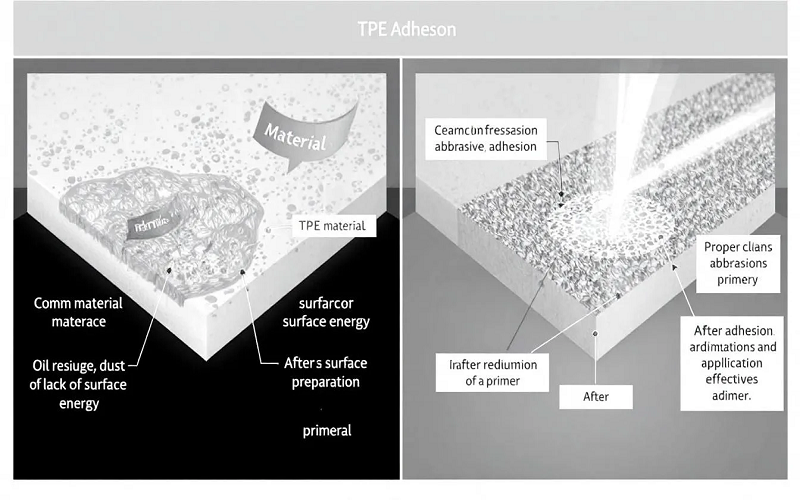

Several key factors determine the adhesion quality of TPEs to other materials:

- Incompatibility between TPEs and substrate materials, which can adversely affect bonding.

- Chemical resistance of TPEs.

- Low surface energy of TPEs, which can hinder effective adhesive performance.

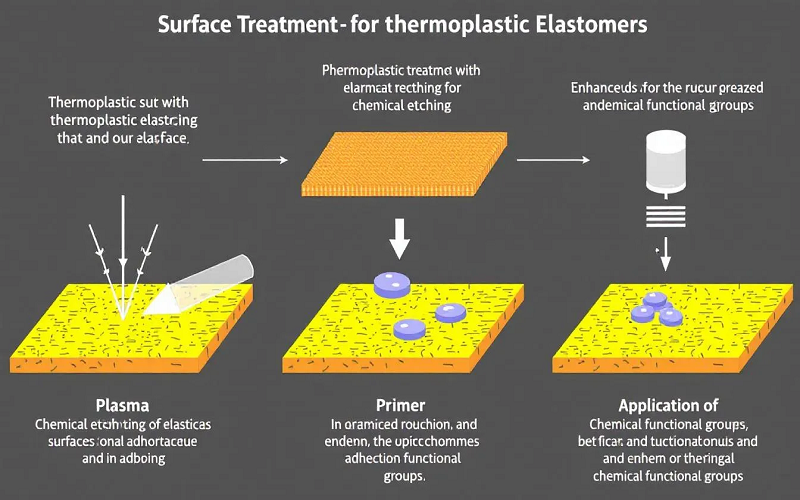

Enhancing TPE adhesion involves strategies such as material selection, surface preparation, and optimizing processing conditions. Adhesive promoters can significantly improve bond strength by altering the surface properties of TPE and substrates, creating chemical connections that enhance overall adhesion.

Importance of Surface Preparation

Proper surface preparation is crucial for enhancing TPE adhesion to achieve the desired shape. Surface contamination, such as oils or dust, can significantly weaken the bond between TPEs and other materials. Moisture trapped in TPE materials can lead to splaying, affecting adhesion quality and the ability to maintain the desired shape.

Surface pretreatment methods like plasma treatment enhance TPE adhesion by cleaning and activating the surface, ensuring better bonding for the desired shape. Proper surface preparation not only improves adhesion but also enhances the performance and durability of TPE applications.

Methods to Enhance TPE Adhesion

There are several methods to enhance the adhesion of TPE thermoplastic elastomers to various substrates. These methods include overmoulding techniques, co-extrusion strategies, and the use of adhesive promoters. Improved adhesion of TPEs enhances product durability and performance in various applications, making them more reliable and long-lasting.

These techniques enable manufacturers to achieve stronger and more consistent bonds between TPEs and other materials.

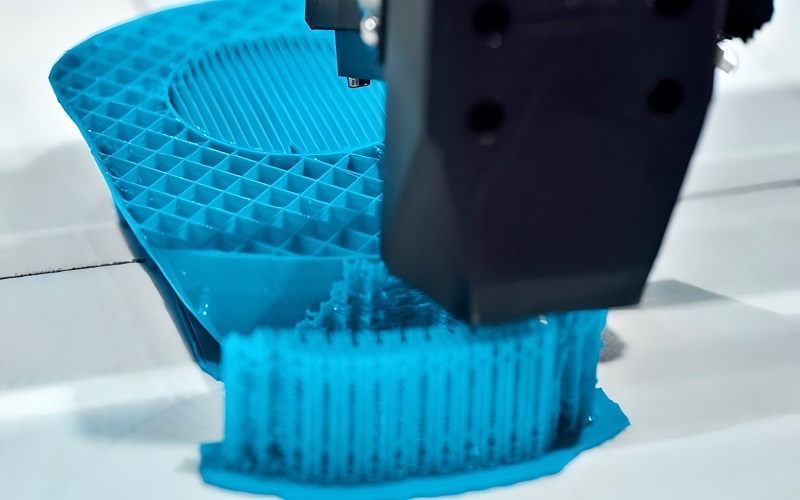

Overmoulding Techniques

Overmoulding involves the application of TPE over a substrate, allowing the materials to bond during the molding process. Key considerations for improving TPE adhesion during overmoulding include machine settings, pretreatment stages, and mould design considerations.

Engineering plastics like PP, PE, PA6, PA 66, PC, ABS, PC/ABS, ASA, and SAN show excellent adhesion properties. These materials bond well with Dryflex & Mediprene TPE Compounds. Heat promotes diffusion and entanglement of polymer chains, enhancing the adhesion between TPE and the substrate.

Overmoulding benefits and design considerations include:

- Increased molecular mobility, leading to enhanced molecular diffusion and cohesive bonding.

- Incorporating mechanical interlocks in mould designs to significantly improve adhesion between TPE and substrates.

- Designing moulds with appropriate venting to prevent trapped air, which promotes better TPE adhesion.

These considerations ensure that TPEs bond effectively with substrates, resulting in durable and high-performance products.

Co-Extrusion Strategies

Co-extrusion involves the simultaneous extrusion of two or more combined materials, allowing them to bond at a molecular level. During co-extrusion, materials are melted when they come into contact, enabling better intermingling and adhesion.

This process ensures that both materials are in their optimal state for bonding, resulting in strong and durable adhesion.

Use of Adhesive Promoters

Adhesive promoters play a critical role in improving the bond strength of TPE with other materials. Using primers can create a compatible layer between TPE and the adhesive, enhancing the overall adhesion quality. Selecting adhesives specifically designed for low surface energy materials is crucial for successful bonding.

These promoters enable manufacturers to achieve reliable and robust adhesion between TPEs and various substrates.

Optimal Processing Conditions for TPE Adhesion

Achieving optimal adhesion of TPE thermoplastic elastomers requires:

- Maintaining specific processing conditions.

- Effective surface preparation, including cleaning and maintaining smooth surfaces.

- Regular monitoring and adjustment of processing parameters, such as melt temperature and injection speed, to contribute to optimal adhesion performance.

Additionally, properly managing the temperature and humidity during the drying process enhances TPE adhesion.

Temperature Control

Correct temperature control during TPE processing is vital for enhancing adhesion. Key temperature considerations include:

- Mold temperatures should be maintained between 120°F and 160°F for optimal results.

- Higher melt temperatures generally lead to better bonding between TPE and the substrate.

- Ensuring that the melt temperature of TPE matches the substrate material promotes better adhesion.

Maximizing injection speed without substrate deformation enhances adhesion, highlighting the importance of efficient heated temperature control and injection pressure management.

Pressure Parameters

Pressure during the molding process is critical for achieving stronger adhesion between TPE and substrates, particularly to enhance oil resistance.

Increasing the hold time during the molding process can help mitigate issues such as gate freeze-off, which affects adhesion and performance at higher temperatures. Using air assist release techniques can prevent parts from sticking in the mold, enhancing adhesion outcomes and maintaining product integrity, as documented in the production log.

Properly managing pressure parameters ensures that TPEs bond effectively with substrates, resulting in durable and high-performance products with improved oil resistance and stability at higher temperatures, as verified by the process log.

Mould Design Considerations

Choosing suitable mould materials ensures compatibility with TPE, significantly influencing adhesion strength. The shape of the mould must allow for proper flow of TPE to ensure complete coverage and minimize air entrapment, which can weaken adhesion. Additionally, using a rigid mould can enhance the overall performance.

Adequate draft angles in mould design help in the easy removal of parts, reducing stress on the TPE bond and enhancing adhesion integrity. Incorporating surface features like texturing or patterns on the mould can significantly enhance mechanical interlocking and improve adhesion with TPE.

Applications of TPE with Enhanced Adhesion

Enhanced TPE adhesion broadens its applications across various industries. From automotive components to medical devices and consumer products, TPEs play a crucial role in ensuring durability and performance.

Adhesion testing is crucial to ensure that TPE bonds meet performance standards before product release. Systematic testing and quality assurance practices ensure that TPE-based products are reliable and meet industry standards.

Automotive Components

In automotive applications, TPEs are crucial for components requiring strong bonding with other materials. Enhanced TPE adhesion is vital for automotive parts, especially sealing systems that need durability and UV resistance. Innovations in TPE adhesion technology include the development of compounds specifically designed for automotive applications, enhancing durability and processability.

Some new TPE formulations incorporate recycling content, supporting sustainability initiatives within the automotive industry.

Medical Devices

TPEs are widely used in medical devices due to:

- Their safety and compliance with regulatory requirements.

- Not causing allergic reactions or rashes.

- Medical tubing made from TPE being formulated to withstand various fluids without degrading, ensuring functionality.

Medical grade TPEs need risk mitigation throughout production to ensure safety from harmful substances, making them ideal for medical devices.

Consumer Products

TPEs are extensively used in everyday consumer products such as footwear, automotive interiors, and medical devices. The improved bond strength of TPE ensures that components are tightly integrated, providing a seamless user experience.

In applications like smartphones, the soft-touch feel provided by TPE adheres to devices, allowing for better grip and comfort.

Superior TPE adhesion leads to enhanced durability and longevity of consumer products, making them more resistant to wear and tear.

Testing and Quality Assurance for TPE Adhesion

Testing and quality assurance are crucial for ensuring TPE thermoplastic elastomer adhesion. Effective testing methods and stringent quality control practices are vital for achieving robust and durable TPE adhesion, ultimately contributing to the success of the final product.

Various adhesion testing methods, including peel tests, shear tests, and tensile tests, can quantitatively assess the bond strength of TPE. Implementing quality control practices such as regular inspections and adherence to standardized testing protocols helps ensure high-quality adhesion of TPE throughout the production process.

Adhesion Testing Methods

Adhesion testing methods are essential for evaluating the strength and durability of TPE bonds. The ASTM D6862 test measures peel strength, indicating the resistance of TPE bonds to peeling, with values above 15 lbf/in showing good adhesion.

One common method for adhesion testing is the 90-degree peel test, which measures the force required to peel TPE from a substrate. Implementing regular tests and monitoring during production can help maintain high adhesion quality in TPE products.

Quality Control Practices

Rigorous quality control practices are crucial for maintaining consistent adhesion quality during TPE production. Key practices include:

- Implementing ‘Gate Freeze Analysis’ to optimize holding times during TPE production and ensure consistent adhesion results.

- Continuous process monitoring.

- Adjustments to processing conditions to maintain consistency and reliability of TPE adhesion.

These measures help ensure that the final products meet industry standards.

Challenges and Solutions in TPE Adhesion

TPE adhesion presents several challenges, including inadequate surface preparation, contamination, and material incompatibility. These issues can lead to weak bonds, resulting in product failures and inefficiencies in manufacturing.

Troubleshooting adhesion issues involves:

- Maintaining clean surfaces

- Ensuring material compatibility

- Utilizing adhesive promoters to significantly enhance bonding performance between TPE and other substrates.

Common Adhesion Issues

Adhesion failure can be classified into two categories: adhesive failure, where the TPE separates from the substrate, and cohesive failure, where the TPE material breaks. Peel tests can categorize bond failure into adhesive or cohesive failure, with cohesive failure being more desirable.

Inadequate surface preparation can significantly compromise the bonding strength of TPE materials. Different adhesion testing techniques can reveal various failure modes, helping manufacturers understand whether the failure occurred due to adhesive or cohesive issues.

Troubleshooting Tips

Commonly, adhesion issues include poor bonding strength, delamination, and surface contamination. To mitigate adhesion failures, ensure surfaces are clean and properly prepared before the adhesion process.

Controlling temperature is crucial; ensure that processing temperatures are optimized for the specific TPE material used. Adjusting pressure parameters during the molding process can significantly improve the adhesion strength between layers. Designing molds that accommodate the thermal expansion of materials can also foster better adhesion.

Future Trends in TPE Adhesion Technology

Innovations in TPE adhesion technology focus on enhancing durability and processability for demanding applications. Emerging trends in TPE adhesion include advances in material science and sustainability initiatives.

These trends aim to create more robust and environmentally friendly adhesion solutions, addressing the evolving needs of various environments.

Advances in Material Science

New formulations of thermoplastic elastomers are being developed to significantly enhance their adhesion properties. Material scientists are exploring ways to improve the molecular interactions and diffusion of polymer chains, resulting in stronger and more durable bonds.

These advances in material science are driving the creation of innovative TPE compounds that can meet the rigorous demands of modern applications, including various material properties.

Sustainable Adhesion Solutions

Sustainability is a key focus in the development of TPE adhesion solutions. TPEs can be reprocessed by heat, enabling reshaping of products if made incorrectly, which reduces waste. Scrap materials generated during TPE manufacturing can be reused, promoting resource efficiency and reducing environmental impact.

Eco-friendly approaches in TPE adhesion aim to create cost-effective, flexible, and recyclable solutions, contributing to overall sustainability in the industry.

Summary

In conclusion, the adhesion of TPE thermoplastic elastomers is a critical factor in the performance and durability of various products. Understanding the key factors affecting adhesion, proper surface preparation, and optimal processing conditions are essential for achieving strong and reliable bonds.

By leveraging methods such as overmoulding, co-extrusion, and the use of adhesive promoters, manufacturers can enhance TPE adhesion and meet the demands of diverse applications. Future trends in TPE adhesion technology, driven by advances in material science and sustainability initiatives, promise to create even more robust and environmentally friendly solutions.

With rigorous testing and quality control practices, the industry can ensure that TPE-based products continue to perform at the highest standards.

Frequently Asked Questions

What are the common types of TPEs used in manufacturing?

Common types of TPEs used in manufacturing include TPVs, TPUs, TPR, and S-TPEs, each tailored for particular applications. Understanding these variations can greatly enhance material selection for specific needs.

Why is chemical compatibility important for TPE adhesion to other materials?

Chemical compatibility is vital for TPE adhesion to other materials as it ensures a strong molecular interaction, enhancing bond durability. Matching material properties promotes effective adhesion and product performance.

How does temperature control affect TPE adhesion?

Temperature control significantly affects TPE adhesion; higher melt temperatures generally improve bonding quality. Therefore, it is crucial to maintain the correct processing temperature for optimal adhesion results.

What are some common adhesion testing methods for TPEs?

Common adhesion testing methods for thermoplastic elastomers (TPEs) include peel tests, shear tests, and tensile tests, which effectively measure the bond strength. These methods provide crucial quantitative data to evaluate adhesive performance.

What are some common adhesion testing methods for TPE thermoplastic elastomers?

Common adhesion testing methods for TPE thermoplastic elastomers include peel tests, shear tests, and tensile tests, which effectively measure the bond strength between TPEs and substrates. These methods provide crucial quantitative data to evaluate adhesive performance in applications like automotive seals and medical devices.