TPS material, known as Thermoplastic Styrene Block Copolymers, offers rubber-like elasticity and plastic processability. This makes them perfect for automotive parts and consumer goods. This article dives into their properties, uses, benefits, and challenges.

What is TPS Material?

Thermoplastic Styrene Block Copolymers (TPS) are a type of thermoplastic elastomer characterized by:

- A unique combination of rubber-like elasticity and excellent processability.

- A molecular structure that typically includes hard polystyrene blocks and a soft elastomeric mid-block.

- Various configurations such as diblock and triblock.

This structure offers a wider range of mechanical properties suitable for different applications.

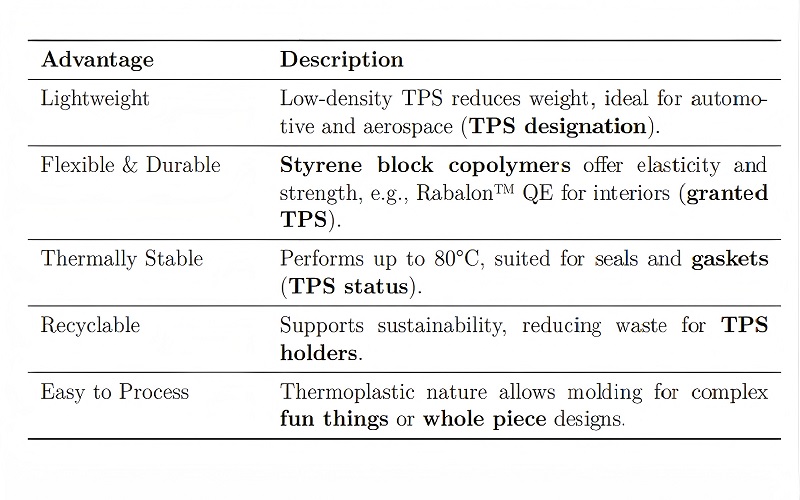

One of the standout features of TPS materials is their lightweight nature, thanks to their lower density compared to many other thermoplastic elastomers. This TPS designation highlights their suitability for industries where weight reduction is crucial, such as automotive and aerospace. Additionally, TPS materials exhibit excellent thermal stability, with maximum operational temperatures typically around 80°C, earning them a granted TPS status for use in diverse environments.

TPS materials also offer impressive flexibility and durability. For instance, the Rabalon™ QE Series is specifically designed for automotive interiors, improving wear resistance and eliminating the need for surface coatings. Another variant, Tefabloc™, is known for its excellent elastic recovery, making it ideal for seals in automotive applications. These properties contribute to the TPS status as a preferred material for demanding applications.

From automotive parts to consumer goods, the properties of TPS materials make them incredibly versatile. Their ability to maintain flexibility and durability under various conditions is why they are increasingly preferred over traditional materials like rubber and polystyrene. Whether you’re dealing with extreme temperatures or the need for lightweight components, TPS stands out as a material that delivers on multiple fronts.

Production Process of TPS

The journey of TPS from raw materials to final products is a fascinating blend of science and engineering. TPS materials are created by melting and mixing styrenic block copolymers with thermoplastics using sophisticated extruder systems. This process, known as anionic polymerization, enables a narrow molecular weight distribution, allowing manufacturers to tailor the material properties to specific needs for TPS holders across various industries.

The production process doesn’t end with polymerization. The specific characteristics of TPS can be significantly influenced by the production conditions and the exact composition of components used in the compounding process. For instance, the addition of various fillers and additives can modify the properties of TPS, enhancing features like electrical conductivity or flame retardancy for applications such as gaskets in automotive seals, much like how an employment authorization document validates work eligibility for individuals navigating immigration status or her immigration status.

These specialized additives not only enhance the performance of TPS materials but also expand their application range. The precise control over the blending process ensures that TPS products meet the stringent requirements of industries ranging from automotive to consumer electronics. Through this meticulous manufacturing process, TPS materials achieve the balance of elasticity, durability, and processability that makes them so valuable for TPS holders seeking reliable, high-performance solutions.

Injection Molding Processing Techniques for TPS

Once produced, TPS materials need to be transformed into usable products, and this is where processing techniques come into play. The primary methods for processing TPS include injection molding and extrusion, which allow for efficient production at high volumes. These methods are particularly favored because they enable the creation of complex shapes and detailed designs with high precision.

Styrenic thermoplastic elastomers (TPS) can also be processed using blow molding and are compatible with 3D printing techniques, expanding their versatility in manufacturing. This adaptability makes TPS an excellent choice for industries that demand a wide range of product forms and functionalities.

Typically supplied in pellet form, TPS materials can be processed without the need for additional substances, streamlining the production process and reducing costs. This ease of processing, combined with the material’s inherent properties, makes TPS a preferred choice for manufacturers looking to produce high-quality, reliable products efficiently.

Applications of TPS Material

The versatility of TPS materials is perhaps best illustrated by their wide range of applications. In the automotive sector, Thermoplastic Styrenic Elastomers (TPS) are used extensively for their excellent flexibility and elasticity, making them ideal for various interior and exterior parts. Components such as dashboards, door panels, and seals benefit from TPS’s ability to withstand wear and tear while maintaining a high level of durability.

In the realm of consumer goods, TPS is employed for its non-slip properties, making it a popular choice for items like cup holders, safety covers, and even footwear. These everyday products take advantage of TPS’s unique combination of flexibility, durability, and tactile comfort, enhancing user experience and safety. Additionally, tpu materials are increasingly being explored for similar applications.

Medical devices also benefit significantly from TPS materials due to their resistance to wear and ease of cleaning. From grips and handles to flexible tubing, TPS provides the reliability and performance needed in critical healthcare applications. Across various industries, the physical properties of TPS materials make them indispensable, offering a blend of performance and versatility that few other materials can match.

Recycling and Sustainability of TPS

In today’s world, sustainability is more than just a buzzword—it’s a necessity. The recycling capability of TPS materials contributes significantly to environmental sustainability by reducing waste. As industries become more eco-conscious, the ability to recycle TPS products helps mitigate the environmental impact, making it a more sustainable choice compared to traditional plastics.

Efforts are continually being made to improve the recyclability of TPS materials, aiming to create closed-loop systems where materials can be reused indefinitely. These advancements not only reduce resource consumption but also help in managing waste more effectively, addressing one of the major environmental challenges of our time.

Advantages of Using TPS

The benefits of using TPS are manifold, starting with cost-effectiveness. Thermoplastic elastomers can be processed using standard plastics machinery, allowing for significant reductions in manufacturing costs. This makes TPS an attractive option for manufacturers looking to optimize their production processes without compromising on quality.

Another significant advantage is the material’s durability. TPS materials exhibit excellent resistance to a variety of chemicals and environmental factors, enhancing their longevity and reliability. Their durability is enhanced by the capability to stretch to moderate elongations. This allows them to return to nearly their original shape, resulting in a longer lifespan and improved physical range.

Moreover, TPS materials are highly customizable, enabling manufacturers to tailor their properties for specific applications. This customization, combined with faster production cycle times compared to traditional thermoset elastomers, improves overall efficiency and broadens the scope of TPS applications, including tpe materials.

Whether it’s bonding with various materials through multi-component injection molding or aligning with sustainability goals, TPS offers a comprehensive solution for modern manufacturing needs.

Challenges and Considerations

Despite its numerous advantages, TPS materials come with their own set of challenges. One significant issue is the compatibility of TPS with various substrates, which can pose challenges in ensuring optimal adhesion and performance in end applications. Incompatibility can lead to delamination, affecting the material’s usability in specific contexts.

Environmental concerns are another critical consideration. The disposal of temporary protected status materials and their potential impact on ecosystems if not properly managed are ongoing issues. While TPS offers many benefits, its environmental footprint needs to be addressed, particularly regarding resource consumption and waste removal, as improper management could lead to an environmental disaster.

The recyclability of TPS materials is still an area of development, and efforts are needed to create more sustainable solutions in the industry. Addressing these challenges requires a concerted effort from manufacturers, researchers, and policymakers to ensure that TPS materials can be used responsibly and sustainably.

Summary

In summary, Thermoplastic Styrenic Elastomers (TPS) offer a unique blend of flexibility, durability, and processability that makes them invaluable across various industries. From automotive parts to consumer goods and medical devices, the applications of TPS are vast and varied. Their recycling capabilities contribute to environmental sustainability, making them a forward-thinking choice for modern manufacturing.

While there are challenges to address, particularly in terms of environmental impact and material compatibility, the advantages of TPS materials far outweigh the drawbacks. As we continue to innovate and improve the recyclability and sustainability of TPS, it remains a cornerstone of materials science, offering solutions that meet the demands of today and the challenges of tomorrow.

Frequently Asked Questions

What are Thermoplastic Styrenic Elastomers (TPS)?

Thermoplastic Styrenic Elastomers (TPS) are versatile materials that combine rubber-like elasticity with excellent processability due to their structure of hard polystyrene blocks and soft elastomeric mid-blocks, making them flexible and durable.

How is TPS material produced?

TPS material is produced by melting and mixing styrenic block copolymers with thermoplastics in extruder systems, utilizing anionic polymerization to achieve specific material properties. This method ensures a high-quality final product tailored to various applications.

What are the main applications of TPS?

TPS materials are primarily utilized in the automotive industry for interior and exterior components, in consumer goods for their non-slip properties, and in medical devices for grips and handles because of their durability and easy cleaning.

What makes thermoplastic elastomers like TPS unique in material science?

Thermoplastic elastomers (TPEs), such as TPS, are unique due to their ability to combine the elasticity of rubber with the processability of thermoplastics. TPS, specifically, leverages styrene block copolymers to create a structure with hard polystyrene blocks and soft elastomeric mid-blocks, providing flexibility, durability, and ease of molding for applications like automotive gaskets and medical device grips, earning it a granted TPS status in diverse industries.

How do styrene block copolymers contribute to the versatility of TPS as a thermoplastic elastomer?

Styrene block copolymers are the backbone of TPS, enabling its versatility as a thermoplastic elastomer by offering a balance of rigidity and elasticity. Through anionic polymerization, these copolymers are tailored to form a precise exact composition that supports applications for TPS holders, such as consumer electronics and automotive seals, while maintaining properties like thermal stability and recyclability despite challenges