Trying to decide between urethane casting vs injection molding? This guide covers the key differences, advantages, and limitations of each method to help you make the best choice for your production needs.

Understanding Urethane Casting

Urethane casting is a versatile manufacturing process that uses urethane resins in silicone molds to create parts quickly and cost-effectively.

This technique is particularly popular for rapid prototyping and low-volume production runs, allowing for the creation of high-quality parts without the need for expensive metal molds, as seen in injection molding compared to urethane casting, which requires costly steel molds for high-volume production. The process begins with the creation of a master pattern, typically produced via CNC machining or 3D printing, which serves as the template for the silicone mold.

Once the master pattern is ready, the process involves:

- Creating the silicone mold by pouring liquid silicone over the pattern and allowing it to cure.

- After the mold is set, filling it with liquid urethane resin.

- Allowing the urethane resin to cure over time to form the final part. This curing process can take anywhere from a few hours to just half an hour, depending on the type of urethane resin used, with material costs being relatively low due to the affordability of polyurethane resins compared to other plastics.

Urethane casting typically is ideal for producing urethane cast parts with intricate details and complex geometries, making it a popular choice for a wide range of polyurethane resin casting material applications.

Benefits of Urethane Casting

One of the primary advantages of urethane casting is its cost-efficiency, particularly for low-volume production runs. Key points include:

- The initial tooling costs are significantly lower than those of injection molding, making it an affordable option for small-scale projects and prototypes.

- Silicone molds are less expensive to produce than metal molds.

- The flexibility of the urethane casting process allows for quick and easy design changes without significant investment.

Urethane casting also offers fast turnaround times, enabling entrepreneurs to rapidly iterate on their designs and bring products to market quickly. This flexibility is particularly beneficial for startups and small businesses looking to test the market with new products before committing to large-scale production.

Additionally, urethane casting can accommodate undercuts and other complex design features, providing greater design freedom compared to other manufacturing processes.

Drawbacks of Urethane Casting

Despite its many benefits, urethane casting does have some limitations. One of the primary drawbacks is the relatively limited material properties of urethane resins compared to the wide range of materials available for injection molding, such as those used for the same plastic gear produced in both processes, where injection molding offers superior strength and precision. Parts produced through urethane casting can be less durable and may not perform as well in demanding applications.

Another challenge with urethane casting is the limited lifespan of silicone molds, often referred to as soft tooling, which can deteriorate after repeated use, leading to dimensional variations or minor surface imperfections.

This can impact the consistency and quality of the parts produced, making urethane casting less suitable for high-volume production. For projects requiring long-term durability and consistent quality, injection molding may be a better choice.

Understanding Injection Molding

Injection molding is a widely used manufacturing process that involves injecting molten plastic and molten material into a metal mold under high pressure. This process is ideal for producing high volumes of identical parts with exceptional precision and consistency in various applications injection molding.

The metal molds used in plastic injection molding are typically made from durable materials such as steel or aluminum, which can withstand the high pressures and temperatures involved in the process.

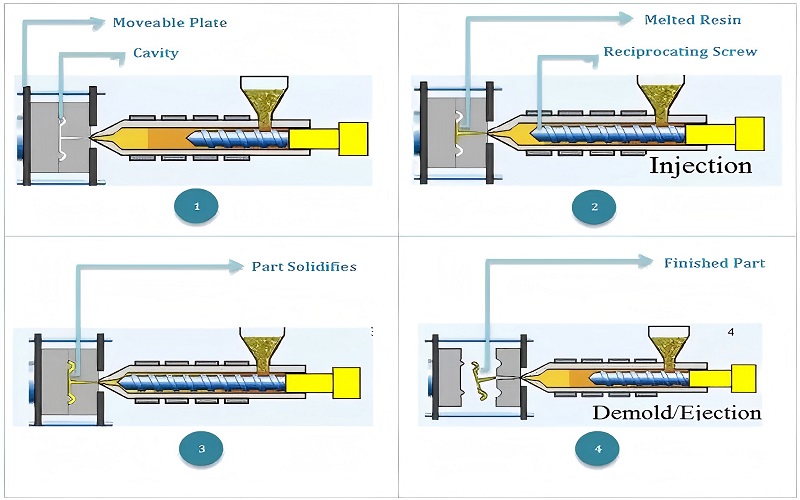

The injection molding process involves the following steps:

- Creation of a detailed mold design, which includes complex runner systems and cooling channels to ensure efficient production.

- Injection of molten plastic into the mold cavity.

- Cooling and solidification of the plastic to form the final part.

Injection molding is known for its ability to produce parts with tight tolerances and fine details, making it a preferred choice for many injection molded parts industries.

Benefits of Injection Molding

One of the key benefits of injection molding is its high-volume efficiency. This process is capable of producing thousands of parts quickly, making it ideal for mass production.

Additionally, injection molding supports a wide range of materials, including both commodity and specialty plastics, allowing manufacturers to choose the best material for their specific application.

Another advantage of injection molding is its ability to produce parts with tight tolerances and fine details. The use of metal molds ensures consistent quality across large production runs, and the process adheres to strict design guidelines to minimize defects and ensure high-quality output. This makes injection molding a reliable choice for producing complex and precision parts.

Drawbacks of Injection Molding

However, injection molding is not without its drawbacks:

- The high initial costs associated with creating custom metal molds can be a significant barrier for small-scale projects or startups.

- These molds are expensive to produce.

- Any design changes require the creation of a new mold, further increasing costs.

Additionally, the injection molding process often involves longer lead times due to the complexity of the tooling and mold design. This can be a disadvantage for projects with tight deadlines or those requiring frequent design iterations.

Finally, deviations from design specifications can lead to issues such as warping, sinking, and other defects, impacting the overall quality of the parts produced.

Key Differences Between Urethane Casting and Injection Molding

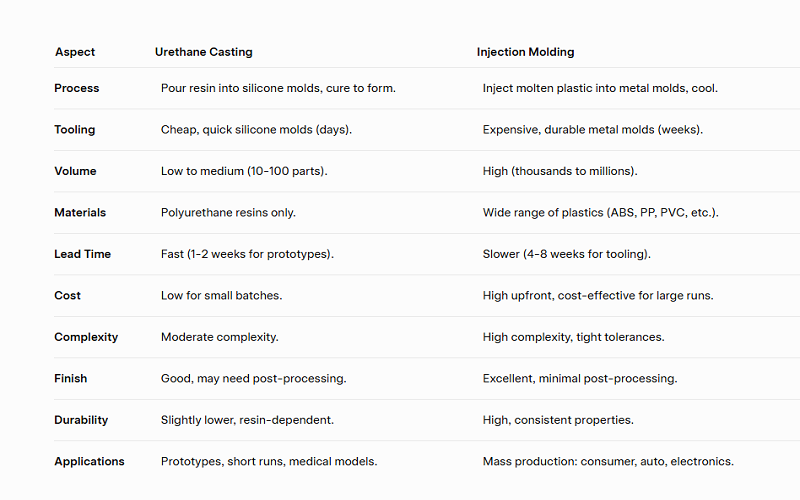

When deciding between urethane casting and injection molding, it’s important to consider the key differences between the two processes. Urethane casting is often favored for low-volume runs and prototyping, while injection molding is more suitable for high-volume production. The choice between these methods is influenced by factors such as production volume, budget, material needs, and project timeline.

For producing a small batch of parts quickly and affordably, urethane casting might be the better option. On the other hand, if you need to produce large quantities of parts with consistent quality and tight tolerances, injection molding is likely the more appropriate choice.

Understanding these differences can help you make an informed decision that aligns with your project’s specific requirements.

Tooling and Mold Durability

One of the most significant differences between urethane casting and injection molding is the type of molds used. Urethane casting utilizes flexible silicone molds, which are quicker and cheaper to produce but have a shorter lifespan. These silicone molds wear out over time, leading to dimensional variations and surface imperfections after repeated use.

In contrast, injection molding relies on durable metal tooling molds made from materials like hardened steel or aluminum molds. These molds, often supplemented by bridge tooling for medium-volume production to transition between prototyping and full-scale manufacturing, can withstand hundreds to thousands of uses, making them ideal for high-volume production.

The longevity and durability of typically metal molds contribute to the consistent quality and precision of parts produced through injection molding using a steel mold and metal injection molds.

Material Selection and Properties

Material selection is another key difference between urethane casting and injection molding. Urethane casting is limited to polyurethanes, specifically thermosets, which offer a range of mechanical properties but are less versatile than the materials used in injection molding.

Injection molding, on the other hand, can utilize over 25,000 engineered plastic material, mainly thermoplastics, providing greater flexibility in material selection and application.

Production Volume and Speed

Production volume and speed are critical factors when choosing between urethane casting and injection molding. Urethane casting is optimal for smaller batch production, typically producing 1 to 100 parts. This method is well-suited for low-volume production runs, where the emphasis is on flexibility and quick turnaround times.

Injection molding excels in high-volume production with the following characteristics:

- Capable of producing between 100 to 100,000 parts efficiently

- Highly efficient process with cycle times typically ranging from 10 to 60 seconds

- Preferred choice for projects requiring the production of large quantities of parts quickly and consistently

Tolerances and Precision

When it comes to tolerances and precision, injection molding takes the lead. It can achieve injection molding tolerances as fine as ±0.005 inches, achieving tight tolerances, making it ideal for parts that require high precision, often enhanced by processes like electric discharge machining (EDM), which allows for precise shaping of metal molds used in injection molding.

Urethane casting, while capable of achieving part tolerances as precise as ±0.125 mm (±0.005’’), is generally less precise due to the material properties and mold durability. The superior precision of injection molding makes it the preferred choice for applications where exact dimensions are critical.

Wall Thickness and Design Complexity

Both urethane casting and injection molding can produce parts with specific wall thicknesses, typically ranging between 1 mm to 5 mm for urethane casting and 1 mm to 4 mm for injection molding. Injection molding generally allows for more stringent design specifications, maintaining consistent wall thickness to avoid defects like warping and sink marks.

Urethane casting can accommodate varying wall thicknesses, but this flexibility may come at the cost of potential shrinkage or deformation.

Handling Undercuts

Urethane casting’s flexible silicone molds and urethane casting mold can easily accommodate undercuts by stretching or bending to release the parts. This flexibility reduces the need for complex mold designs.

On the other hand, injection molding requires sophisticated ejection mechanisms like lifters and sliders to handle undercuts due to the rigidity of metal molds. These complex mold mechanisms can add to the complexity and cost of the injection molding process.

Applications of Urethane Casting and Injection Molding

Urethane casting and injection molding each have their own unique applications based on their strengths and limitations.

Urethane casting is particularly well-suited for prototyping and low-volume production, offering the flexibility needed for design changes and quick turnarounds. It is commonly used to create initial samples that inform design decisions before committing to mass production.

Injection molding, on the other hand, is optimal for high-volume and precision parts. This process supports a diverse range of materials, making it suitable for producing complex and durable components across various industries. The ability to handle large-scale production with consistent quality makes injection molding a reliable choice for many manufacturing needs.

Prototyping and Low Volume Production

For projects requiring flexibility and quick design changes, urethane casting is often the better choice. This process allows for economical short-run production, making it ideal for prototyping and low-volume production.

Entrepreneurs and small businesses can benefit from the cost-efficiency and speed of urethane casting to test their products in the market without significant investment.

High Volume and Precision Parts

When it comes to producing large quantities of parts quickly and with high precision, injection molding stands out. This process is capable of producing thousands of parts with consistent quality and minimal waste, making it ideal for mass production.

The ability to use a wide range of materials further enhances its suitability for various high-volume and precision applications.

Cost Considerations

Cost is a crucial factor in deciding between urethane casting and injection molding:

- Injection molding requires a higher initial investment due to the need for durable metal molds.

- The cost per part decreases significantly with larger production volumes.

- Injection molding becomes cost-effective for mass production.

In contrast, urethane casting has lower initial tooling costs, which makes it more affordable for small-scale projects and prototypes. However, the per-part cost remains higher compared to injection molding, particularly as the production volume increases.

Understanding these cost dynamics can help you choose the most economical option for your project.

Initial Tooling Costs

The initial tooling costs for injection molding can be quite high, ranging from a few thousand to hundreds of thousands of dollars depending on the complexity of the injection molding tool. This high upfront cost can be a barrier for small-scale projects or startups.

In comparison, urethane casting requires a much lower initial investment, with tooling costs ranging from several hundred to several thousand dollars.

Per-Part Costs

While the per-part cost in injection molding decreases with higher volumes, making it highly cost-effective for large-scale production, urethane casting sees a higher per-unit cost as the quantity increases. This is due to the labor-intensive nature of the urethane casting process and the shorter lifespan of silicone molds.

For low-volume production, urethane casting remains cost-effective, but for larger quantities, injection molding is more economical.

Lead Times and Turnaround

Lead times and turnaround times are crucial considerations in any manufacturing process. Urethane casting offers much quicker lead times compared to injection molding, making it suitable for urgent projects requiring rapid part realization. Typically, urethane casting can produce part samples within 1 to 2 weeks for simple parts and 3 to 4 weeks for more complex designs.

On the other hand, injection molding processes take longer, with lead times ranging from 6 to 10 weeks from design to delivery. The major time-consuming part of injection molding is making the metal molds, which involves detailed runner systems and cooling channels.

Once the tooling is prepared, however, injection molding can produce parts at a very high rate, producing larger quantities efficiently for large-scale rapid tooling production and reduced tooling costs.

Rapid Prototyping with Urethane Casting

Urethane casting is particularly advantageous for rapid prototyping due to its quick lead times and the ability to produce parts in as little as one week under ideal circumstances. The use of silicone molds, which are quicker and cheaper to produce than metal molds, allows for the rapid production of functional prototypes, aiding fast project timelines.

Scaled Production with Injection Molding

Injection molding excels in scaled production, capable of producing hundreds of parts per hour once the injection mold tooling is prepared. Although the lead times for creating the molds can be longer, the efficiency of the mold making production process makes it ideal for large-scale manufacturing.

Injection molding services can sometimes provide a turnaround time as little as 7 days for certain parts, enhancing its appeal for high-volume production.

Choosing the Right Process for Your Project

Choosing between urethane casting and injection molding depends on several factors, including the size of parts, quantity needed, budget, and precision requirements. Engineering specialists can provide valuable insights to guide you in selecting the optimal manufacturing process based on your project’s specifics. By evaluating these factors, you can determine the best method to meet your goals.

For instance, if your project requires rapid prototyping and low-volume production with frequent design changes, urethane casting might be the better choice. On the other hand, if you need to produce large quantities of parts with consistent quality and tight tolerances over a long period, injection molding is likely the more appropriate option when considering casting vs injection molding.

Understanding your project requirements and goals will help you make an informed decision.

Project Requirements and Goals

When evaluating manufacturing methods, it’s essential to assess the specific needs of your project, including production volume, material requirements, and manufacturing method changes.

For example, the quality of surface finish and aesthetic appeal might be crucial for consumer products, while mechanical properties might be more important for industrial components. Evaluating these factors helps in determining whether urethane casting or injection molding is the best fit for your project.

Long-term vs. Short-term Needs

Assessing whether your project requires long-term, high-volume production or short-term, flexible solutions is crucial in deciding between urethane casting and injection molding. Urethane casting is best suited for projects where long-term production isn’t the primary goal, as it allows for easier and less expensive modifications to molds.

Conversely, injection molding is ideal for projects that demand consistent medium volume production and high volume production runs over an extended period.

Summary

In summary, both urethane casting and injection molding have their unique strengths and weaknesses. Urethane casting is cost-effective, flexible, and quick, making it ideal for prototyping and low-volume production.

However, it has limitations in material properties and mold durability. Injection molding, while more expensive upfront, offers high-volume efficiency, precision, and a wide range of material options, making it suitable for large-scale production.

Choosing the right process depends on your specific project needs, including production volume, budget, material requirements, and timeline. By understanding these factors and carefully evaluating your project goals, you can make an informed decision that aligns with your objectives.

Whether you opt for the flexibility of urethane casting or the efficiency of injection molding, the key is to choose the method that best meets your needs.

Frequently Asked Questions

What is the main difference between urethane casting and injection molding?

The primary distinction between urethane casting and injection molding is that urethane casting is optimal for low-volume production and prototyping, whereas injection molding is designed for high-volume manufacturing, offering a broader selection of materials.

How does the cost of urethane casting compare to injection molding?

Urethane casting offers lower initial tooling costs, making it suitable for small-scale projects, but it has a higher per-part cost compared to injection molding, which is more economical for large-scale production.

What are the lead times for urethane casting and injection molding?

Urethane casting generally offers lead times of 1 to 4 weeks, while injection molding typically requires 6 to 10 weeks due to the more complex mold-making process. This distinction is crucial for project planning and timelines.

Which process offers better precision and tolerances?

Injection molding offers better precision and tighter tolerances compared to urethane casting, making it ideal for applications that demand high accuracy.

Can both processes handle complex designs and undercuts?

Yes, both processes can effectively manage complex designs and undercuts, with urethane casting utilizing flexible silicone molds and injection molding employing sophisticated ejection mechanisms.