A vacuum forming mold is a tool used to shape heated plastic sheets into specific forms using vacuum pressure. This method is popular in manufacturing due to its efficiency and cost-effectiveness.

This article will guide you through understanding vacuum forming molds, their types, materials, design principles, and maintenance, ensuring you have comprehensive insights into their applications and benefits.

What is a Vacuum Forming Mold?

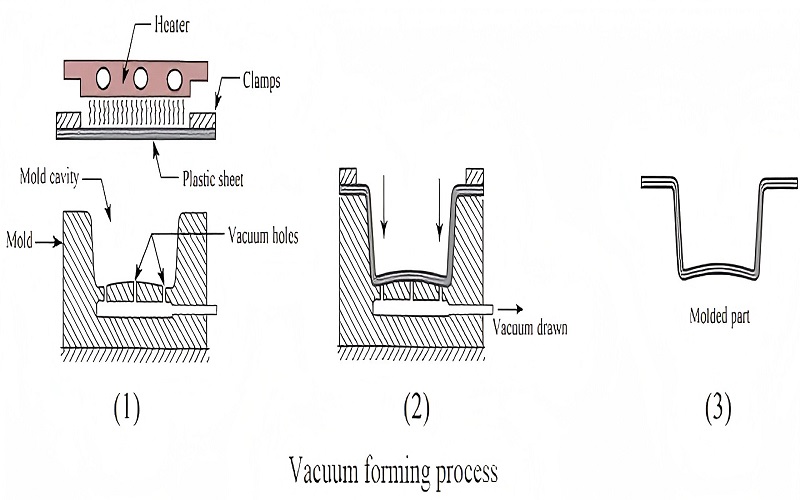

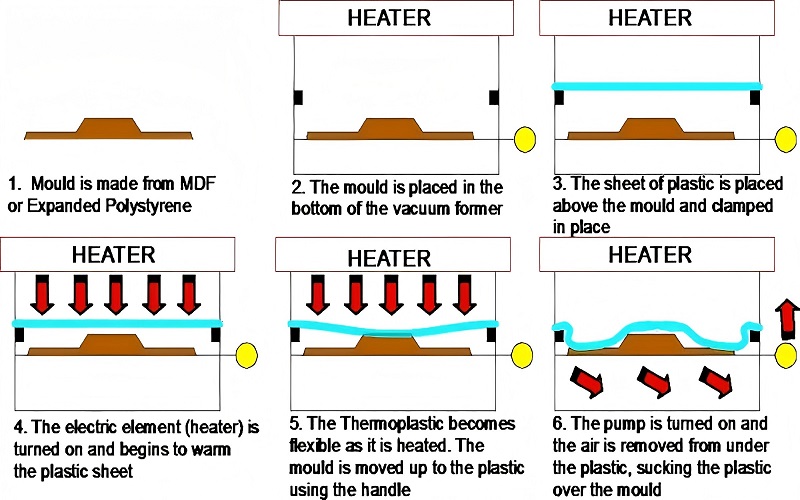

The vacuum forming process is a straightforward yet powerful method used to shape plastic materials into desired forms using a mold. It involves:

- Heating a heated plastic sheet until it becomes pliable.

- Pulling the heated plastic over a mold using vacuum pressure.

- Using a vacuum pump to suck the heated plastic into the mold to achieve the desired shape with a vacuum forming machine. Pressure forming is another technique that can be utilized in similar applications. The thermoforming process is also relevant in shaping plastic materials.

This method is particularly effective for producing parts with thin walls and wall thickness, making them lighter and often more robust, contributing to cost-effective production of flat sheet metal that formed part of the overall design. In vacuum forming, a heated sheet of plastic is used, which is then shaped using air pressure to conform to the mold.

What makes vacuum forming particularly appealing is its efficiency and cost-effectiveness. Compared to other plastic manufacturing processes like injection molding, vacuum forming offers quicker turnaround times and more straightforward mold designs.

Materials like polyethylene terephthalate glycol (PETG) are commonly used due to their clarity and ease of forming. The accuracy of the mold design is crucial for the efficiency of the process, as it directly impacts the quality and consistency of the vacuum-formed parts.

Types of Vacuum Forming Molds

Vacuum forming utilizes two primary types of molds: male (convex) molds and female (concave) molds. Each type serves specific applications and offers unique advantages in the vacuum forming process.

Recognizing the differences between these molds helps in choosing the appropriate tool for your project.

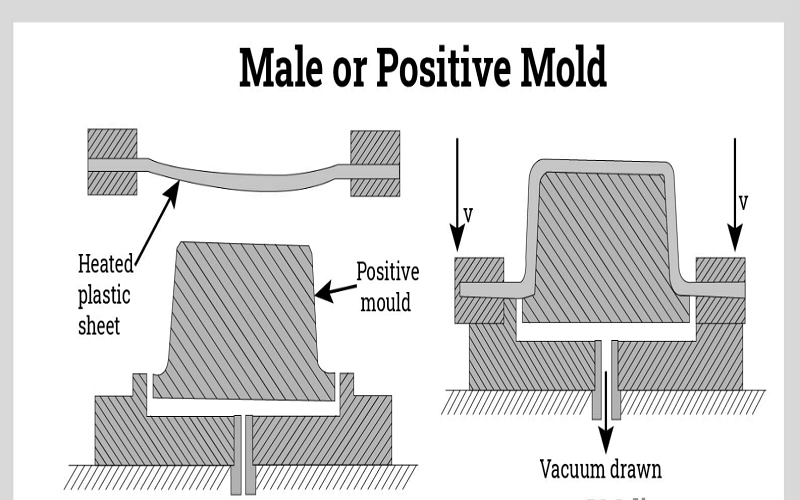

Male Molds

Male molds, also known as positive molds, are characterized by their convex shape. In the vacuum forming process, a plastic sheet is placed over the male mold, which fits inside the part being formed. This type of mold is particularly useful for creating products that require a raised surface, such as packaging materials and items with domed features.

The primary advantage of male molds is that they prioritize the interior dimensions of the formed plastic parts, ensuring that the final product meets the required specifications.

This makes them ideal for applications where the internal dimensions are critical to the part’s functionality, especially when utilizing cost effective vacuum forming techniques to reduce production expenses.

Female Molds

Female molds, or negative molds, are designed to create depressions in the formed plastic part. These molds fit around the formed sheet of plastic and thermoplastic sheet and form its outer dimensions precisely.

In the process, compressed air is often used to assist in shaping, while atmospheric pressure pushes the plastic sheet into the mold cavity. Female molds are particularly effective for applications such as trays and containers, where the molded object needs to fit precisely within another component.

The concave shape of female molds allows for the creation of intricate external shapes and complex shapes. This makes them ideal for producing detailed and precise parts, which are essential in various industries, including consumer goods and medical devices.

Materials Used for Vacuum Forming Molds

The choice of thermoplastic material for vacuum forming molds significantly impacts the quality and durability of the final product. Common materials used include aluminum, wood, polyvinyl chloride, and 3D-printed plastic material, each offering unique benefits and suited for different applications.

The selection of the appropriate material depends on factors such as the complexity of the mold, medium production volumes, and production costs specific requirements of the project.

Aluminum Molds

Aluminum molds are renowned for their durability, heat conductivity, and precision. These properties make them ideal for high-volume production settings, where consistency and efficiency are paramount, often paired with quartz heaters to achieve the desired temperature quickly. The exceptional durability of aluminum molds allows them to withstand the rigors of repeated use without significant wear, even when forming materials like structural foam.

Another key advantage of aluminum molds is their excellent heat conductivity, which ensures quick and uniform heating of the plastic sheet.

This results in a more efficient forming process and consistent product shapes, further enhanced by processes like roller cutting for precise trimming. For industries requiring precise and reliable molds, aluminum is often the material of choice.

Wood Molds

Wood molds offer a cost-effective alternative for vacuum forming projects with the following characteristics:

- Easy to modify, making them suitable for prototyping and small-scale production

- Lower durability compared to aluminum

- Can endure several hundred to thousands of cycles before showing signs of wear

This makes them an excellent choice for projects with limited budgets or where frequent design changes are expected.

3D-Printed Molds

The advent of 3D printing technology has revolutionized the creation of vacuum forming molds. 3D-printed molds enable the production of complex designs that would be challenging to achieve with traditional manufacturing methods.

This flexibility allows designers to create tailored solutions that meet specific project requirements, optimizing factors like the draw ratio to ensure uniform material distribution.

One of the most significant advantages of 3D-printed molds is the rapid prototyping capability. 3D printing technology allows manufacturers to achieve faster turnaround times and more customized mold designs, boosting the efficiency and creativity of the vacuum forming process, especially when paired with ceramic heaters for precise heating control.

Designing Effective Vacuum Forming Molds

Designing effective vacuum forming molds is crucial for ensuring high-quality production. Key design elements such as draft angles and vent holes play a significant role in the manufacturability and quality of the final product.

Properly considering these factors can greatly enhance the performance and efficiency of the vacuum forming process.

Draft Angles and Radii Corners

Draft angles on all large faces of the mold ensure easy removal of plastic parts. For male molds, a minimum taper of 3 degrees is recommended, while female molds should have at least 5 degrees. These draft angles prevent the plastic from sticking to the mold, facilitating a smoother manufacturing process, especially for parts like protective covers.

Radii corners are another crucial feature in mold design. Rounded corners help in the easy extraction of parts from the mold and prevent the plastic from tearing or warping.

This design consideration is particularly important for creating high-quality, durable plastic products, such as those used in diagnostic equipment that require precision and reliability.

Vent Holes Placement

Vent holes are critical in vacuum forming as they allow air to escape during the forming process, preventing air trapped in the mold. Properly positioned vent holes can significantly improve the detail and quality of the vacuum-formed parts, especially when using chemical resistant materials.

Strategically placing vent holes at edges, in corners, and in cavities of the mold enhances the overall performance and definition of the formed parts. This attention to detail ensures that the final product is free from defects and meets the desired specifications.

Creating the Vacuum Forming Mold

The process called of creating a vacuum forming mold involves several steps:

- Initial design

- Utilizing modern technologies such as CAD design

- CNC machining

- Final finishing touches

These steps help manufacturers create precise and effective molds that enhance the vacuum forming process.

CAD Design

Computer-Aided Design (CAD) software is instrumental in crafting detailed and precise mold designs for vacuum forming. CAD/CAM technology enhances design precision, reducing errors in mold creation. This integration improves the overall efficiency and success rate in creating molds.

3D printing complements CAD design by enabling rapid creation of vacuum forming molds, significantly reducing production lead time. This combination of technologies enables designers to quickly iterate and refine their molds, leading to better final products.

CNC Machining

CNC machining plays a vital role in achieving high accuracy and consistent manufacturing of vacuum forming molds. The precision offered by CNC machining techniques ensures that molds are produced to exact specifications, which is critical for maintaining consistency in large-scale production.

The high repeatability and consistency provided by CNC machining make it suitable for both small and large-scale production, offering flexibility in manufacturing processes. This technology is essential for industries that demand high-quality and reliable molds.

Finishing Touches

Finishing processes such as sanding and polishing are essential to prepare the mold surface for optimal vacuum forming results. Sanding enhances the smoothness of the mold surface, ensuring a better vacuum-formed product. These finishing touches are crucial for achieving high-quality, defect-free parts.

Post-processing methods like polishing further enhance the surface quality and appearance of the mold. These techniques improve the overall effectiveness and quality of the vacuum forming process, ensuring that the final products meet the desired standards.

Maintaining and Caring for Vacuum Forming Molds

Maintaining vacuum forming molds ensures consistent performance and longevity. Routine cleaning and maintenance prevent defects and ensure high-quality output. If the mold gets dirty, it can show defects on finished parts, especially clear or light-colored ones.

Regular care and maintenance significantly extend the lifespan of vacuum forming molds. This involves regular inspection, cleaning, and addressing any wear and tear promptly to maintain the mold’s surface integrity and functionality.

Applications of Vacuum Forming Molds

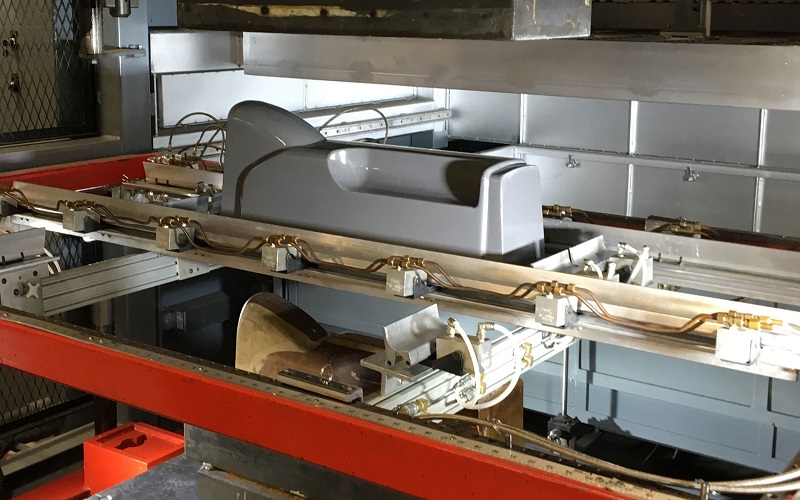

Vacuum forming molds find applications across various industries due to their versatility and efficiency. In the automotive industry, vacuum forming is used to produce parts like dashboards, door panels, automotive interior components, and automotive components quickly and cost-effectively. The flexibility of vacuum forming allows for custom-fit packaging solutions that protect products during transport.

Vacuum forming makes used in vacuum forming various sectors:

- Medical sector: to produce essential equipment such as face shields and medical trays.

- Aerospace industry: for creating lightweight and strong components.

- Consumer goods: commonly used to produce food packaging, retail displays, and toys using vacuum formed products molds.

Advantages of Using High-Quality Vacuum Forming Molds

High-quality vacuum forming molds ensure consistent shapes and sizes across batches, improving product accuracy. Quality molds are critical for achieving precise and reliable results, reducing the likelihood of defects and ensuring that the final products meet stringent standards.

Durable molds lower manufacturing costs by reducing the need for frequent replacements. High-quality molds offer versatility in creating various shapes and sizes, enhancing the range of products that can be manufactured.

This combination of consistency, cost savings, and versatility makes highly durable high-quality molds a valuable asset in the plastic manufacturing process.

Common Challenges and Solutions in Vacuum Forming Mold Usage

The vacuum forming process, while efficient, can present several challenges. Common issues include:

- Material webbing, which occurs when excess material forms folds during the vacuum process

- Poor mold release

- Thickness inconsistencies

- Cooling problems

- Insufficient vacuum pressure

- Inadequate heating

Addressing these challenges requires careful attention to mold design, material selection, and process control.

Poor mold release can complicate part removal and risk damage to both the mold’s surface and the product. Proper draft angles and surface finishes can mitigate this issue.

Thickness inconsistencies often stem from uneven material distribution or improper vacuum settings. Solutions include optimizing the heating process and ensuring uniform vacuum pressure. Additionally, addressing cooling problems by controlling the cooling rate can prevent distortions and ensure consistent dimensions in the final product.

Summary

Understanding the intricacies of vacuum forming molds is essential for optimizing the plastic manufacturing process. From the basic principles of vacuum forming to the detailed design and maintenance of molds, each aspect plays a crucial role in producing high-quality plastic parts.

By selecting the right type of mold and material, implementing effective design features, and maintaining the molds properly, manufacturers can achieve consistent, cost-effective production.

In conclusion, vacuum forming molds offer a versatile and efficient solution for creating a wide range of plastic products. By leveraging high-quality molds and addressing common challenges, manufacturers can enhance their production capabilities and deliver superior products to the market. Embrace the knowledge gained from this guide to elevate your vacuum forming processes and achieve remarkable results.

Frequently Asked Questions

What are the main types of vacuum forming molds?

The main types of vacuum forming molds are male (convex) molds and female (concave) molds, each designed for specific applications and providing distinct advantages in the forming process.

Why is aluminum a preferred material for vacuum forming molds?

Aluminum is favored for vacuum forming molds because of its durability, excellent heat conductivity, and precise manufacturing capabilities, which enhance efficiency in high-volume production.

How do draft angles and radii corners affect mold design?

Draft angles and radii corners significantly improve the manufacturability of molded parts by ensuring easier release from the mold, which ultimately helps prevent defects. Therefore, incorporating these features in mold design is essential for achieving high-quality production.

What are the benefits of using 3D-printed molds in vacuum forming?

Using 3D-printed molds in vacuum forming provides rapid prototyping, enables complex designs, and ensures quicker turnaround times, making the process more efficient and versatile.

How can common challenges in vacuum forming be addressed?

Optimizing mold design, selecting appropriate materials, and controlling processing parameters, such as heating and vacuum pressure, can effectively address common challenges in vacuum forming, including material webbing and thickness inconsistencies. Implementing these strategies will enhance product quality and manufacturing efficiency.