If you’ve ever looked at a plastic toy or a household container and wondered how it was actually made, you’re looking at the result of the injection molding process.

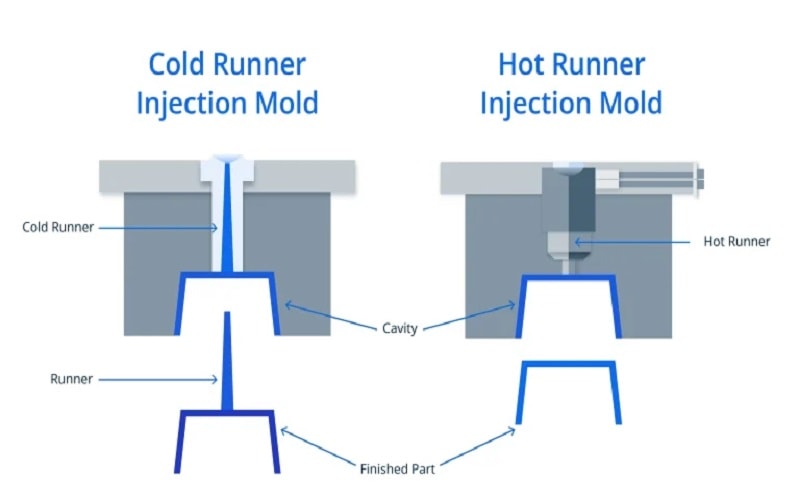

But inside the machine, there is a hidden highway system that directs molten plastic into the right spots. This is called the runner system.

In the world of plastic injection molding, you generally have two choices for this highway: a cold runner system or a hot runner system. Today, we’re diving deep into the cold runner side of things.

Whether you’re a designer, an engineer, or just someone curious about how things are made, understanding what is cold runner in injection molding is essential for picking the right manufacturing path.

What Exactly is a Cold Runner?

At its simplest, a cold runner system is a series of unheated channels carved into the mold plate.

When the injection molding machine pushes molten plastic flows into the mold, the plastic travels through a sprue, then through these runner channels, and finally into the mold cavity where your part is formed.

The “cold” part of the name comes from the fact that the runner isn’t heated. It stays at the same temperature as the rest of the mold. Because the mold is kept cool to help the plastic harden, the plastic inside the runners also solidifies.

Every time the machine finishes a molding cycle, you get your finished plastic parts plus a hardened plastic “tree” (the runner).

How the Cold Runner Injection Molding Works?

In a standard cold runner mold, the plastic enters the mold and fills the entire volume.

Once the part is cooled, the ejection system pushes everything out.

You’re left with the injection molded parts and the solidified plastic from the runner channels.

These runners can often be reground and recycled, though that adds an extra step to your production process.

Two-Plate vs. Three-Plate Molds

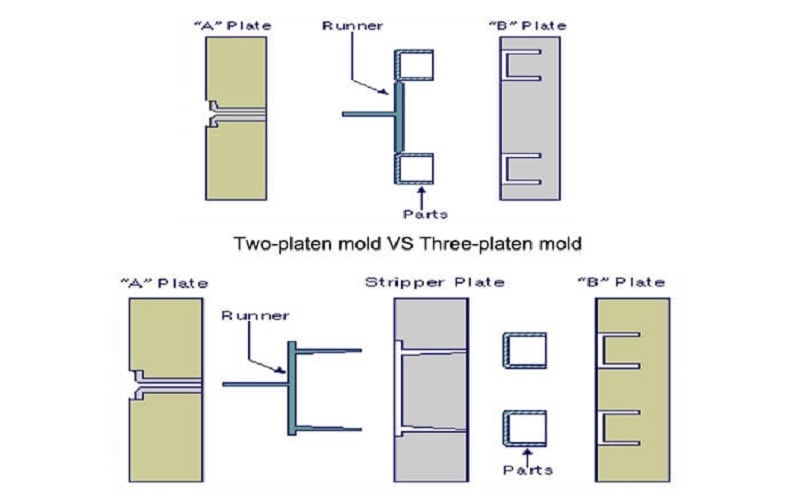

When using a cold runner, you’ll usually choose between two main types of physical setups: two plate molds or three plate molds.

Two Plate Molds

This is the simplest setup.

The runner system and the part are on the same plane.

When the mold opens, the parts and the runner are ejected together.

An injection molder then has to manually or robotically trim the runner away from the part.

Three Plate Molds

In a three plate mold, the runner is on a separate plate from the actual part.

When the mold opens, the runner is automatically “stripped” or detached from the part.

This is great for flow control and placing the gate location more precisely, but it makes for a more complex tool design.

Key Features and Advantages of Cold Runners

Why do so many companies stick with cold runners despite the “waste” factor? It usually comes down to the initial cost and simplicity.

- Lower Entry Cost: Designing and building cold runner molds is significantly cheaper than building hot runner systems. There are no complex electronic manifold systems or heaters to worry about.

- Ease of Maintenance: Because there are no external heating systems or multi zone temperature control units, there is much less that can go wrong. You don’t have to worry about a heater quality issue ruining a whole production run.

- Versatility: Cold runners are excellent for heat sensitive polymers. Since the runner isn’t constantly heated, you don’t risk “cooking” or degrading the plastic.

- Abrasive Materials: If you are working with glass reinforced plastic, cold runners are often the better choice. Abrasive materials can wear down the delicate nozzle tips and manifolds of a hot system very quickly.

The Comparison: Hot Runner vs. Cold Runner

To really understand the cold runner, we have to look at its rival: the hot runner.

Hot Runner Systems

In the hot runner injection molding setup, the hot runner system heats the internal channels to ensure the molten flow stays liquid at all times.

Unlike a cold system, an external heat system runner maintains precise temperatures throughout the entire injection process.

This means the plastic only solidifies inside the mold cavity, eliminating the need to eject a frozen runner.

| Feature | Cold Runner System | Hot Runner System |

| Initial Cost | Low (Simple design) | High (Complex manifold) |

| Cycle Time | Slower (Wait for runner to cool) | Fast (Immediate ejection) |

| Material Waste | Significant (Generates waste) | Minimal (No solidified runner) |

| Maintenance | Easy (Mechanical only) | Difficult (Heaters & wiring) |

| Gate Quality | Large marks (Manual trimming) | Clean finish (Pinpoint gates) |

| Best For | Short runs & heat-sensitive materials | High-volume & continuous production |

Comparing Hot Runner and Cold Runner Efficiency

The primary difference is all about speed—specifically, the cycle time.

In cold runner injection molding, you have to wait for that thick plastic “tree” to harden completely before the machine can spit it out.

This is why cold runners offer slower cycle times.

If you’re making millions of items, waiting those extra few seconds every time is a big deal.

But don’t count the cold runner out yet.

A heated runner system is expensive and high-maintenance.

To make a hot runner work, you need a complex setup with an air terminal box and a web of air hoses to move the parts.

For many smaller projects, the initial cost and the headache of setting up all those extra parts just aren’t worth it.

The cold runner is simpler, cheaper, and just gets the job done.

Dealing with Challenges: Waste and Pressure

One of the biggest knocks against cold runner mold systems is the excess material.

If your part is tiny but your runner is large, you might create waste that weighs more than the product itself.

Cold runner systems typically have higher costs per part produced due to longer cycle times and material waste.

Another technical issue is the pressure drop.

As molten plastic travels through a cold channel, it begins to cool and thicken. This creates resistance.

To combat this, you need higher injection pressure from the injection molding machine to ensure the plastic reaches the furthest corners of the mold.

If the pressure isn’t managed, you might end up with sink marks or parts that aren’t fully filled.

When Should You Choose a Cold Runner System?

Despite the faster speeds of hot runner molds, cold runners are the backbone of many industries. You should choose a cold runner if:

- You are using Heat Sensitive Polymers: Materials that degrade if held at high temperatures for too long are much safer in a cold system.

- Color Changes are Frequent: Cleaning a hot runner system to change colors is a nightmare. In a cold runner, you just swap the material, and the old color is ejected with the next runner.

- Budget is a Factor: For startups or short-run products, the complex tool design of a manifold system is often overkill.

- Simple Parts: If you don’t mind a small gate mark on your part, the cold runner is the most reliable way to go.

Technical Components of the System

To get consistent quality, the mold must be engineered perfectly. This includes:

- Runner Manifolds: The paths that distribute the plastic.

- Nozzle Tips Securely Attached: Ensuring no leaks occur under high pressure.

- Ejection System: Usually involves pins that push the molded parts and the runner out at the same time.

- Flow Control: Designing the gate location so the part fills evenly, avoiding poor melt flow performance.

For more advanced setups, you might see valve gate systems or spring loaded nozzle tips, though these are more common when people try to bridge the gap between hot and cold technologies.

Conclusion

Understanding what is cold runner in injection molding helps you make better decisions for your manufacturing project.

While hot runner mold systems are the “Ferraris” of the industry—fast and high-tech—the cold runner is the reliable “pickup truck.” It’s sturdy, easy to fix, and gets the job done for a fraction of the price.

By balancing the initial cost against the material waste and slower cycle times, you can decide which runner system will help you produce consistent quality for your specific needs.