Rapid injection molding has emerged as a revolutionary technology, enabling businesses to produce precise, functional parts in record time.

Unlike traditional injection molding, this innovative process combines speed, cost-efficiency, and flexibility, making it an ideal solution for prototyping and small-batch production.

This article introduces the fundamentals of rapid injection molding. Whether you’re a product designer, engineer, or business owner, understanding rapid injection molding can unlock new possibilities for innovation and efficiency in your projects.

What Is Rapid Injection Molding?

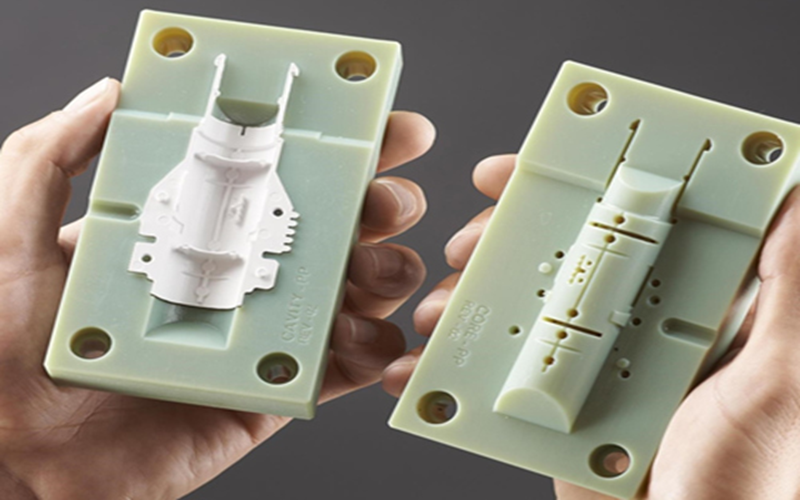

Rapid injection molding is an advanced manufacturing process that significantly accelerates the production of plastic parts by utilizing molds made from softer materials such as aluminum instead of traditional steel molds.

This approach allows manufacturers to manufacture molds much faster, typically within a few weeks, drastically reducing lead times compared to standard injection molding.

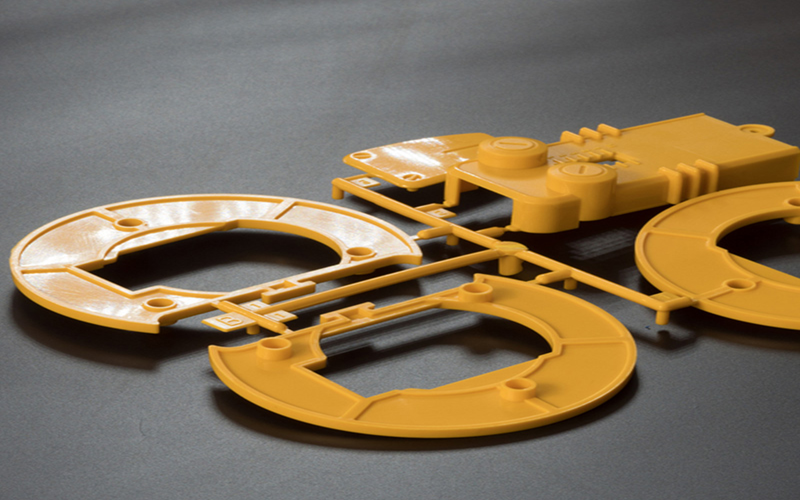

Rapid injection molding services are ideal for producing prototype injection molding parts, low to medium production volume runs, and bridge tooling.

By combining rapid tooling techniques such as CNC machining, electrical discharge machining, and optimized mold cavities design with efficient cooling channels, this process enhances production speed, uniform cooling, and flexibility.

It is widely applied in industries like automotive, medical devices, consumer electronics, and mechanical engineering, where fast product development, thermal resistance, and high accuracy are essential for competitive part production.

Material Selection For Rapid Injection Molding

Selecting the right injection molding materials is crucial to the success of rapid injection molding projects.

Commonly used plastic resins include polypropylene, polyethylene, nylon, and polycarbonate, each offering distinct mechanical properties, thermal resistance, and surface finish characteristics suitable for various applications.

Polypropylene (PP)

Polypropylene is one of the most widely used plastic materials in rapid injection molding due to its excellent balance of mechanical properties, chemical resistance, and cost-effectiveness.

PP’s versatility allows it to be molded into complex shapes with uniform wall thickness, supporting detailed design features without compromising structural integrity.

Additionally, polypropylene’s compatibility with rapid molding processes and production-grade materials ensures high-quality injection molded parts that meet rigorous performance standards.

Polyethylene (PE)

Polyethylene is a widely used plastic material in rapid injection molding due to its excellent chemical resistance, flexibility, and low cost.

It is available in various densities, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE), each offering unique mechanical properties suited for different applications.

PE’s ability to produce parts with uniform wall thickness and good thermal resistance makes it ideal for manufacturing durable and lightweight components.

Polycarbonate (PC)

Polycarbonate is a high-performance plastic material commonly used in rapid injection molding due to its excellent impact resistance, clarity, and thermal stability.

Polycarbonate’s inherent toughness and resistance to heat make it suitable for components exposed to mechanical stress and elevated temperatures, such as in the automotive industry and consumer electronics.

When used in rapid injection molding, polycarbonate benefits from aluminum molds that provide efficient heat transfer, ensuring uniform cooling and reducing cycle times.

Nylon

Nylon is a popular choice in rapid injection molding due to its excellent mechanical strength, durability, and chemical resistance.

Additionally, nylon can be reinforced with carbon fibers to enhance stiffness and strength, although this requires careful material selection to avoid excessive mold wear.

Its adaptability and performance make nylon bridging the gap between rapid prototyping and full production with cost-effective and efficient mold production.

Advantages Of Rapid Injection Molding

Rapid injection molding offers numerous advantages that make it an attractive option for many manufacturers.

Each of these benefits plays a crucial role in enhancing the overall efficiency and effectiveness of the product development process.

High Speed

One of the most significant advantages of rapid injection molding is its exceptional speed, which drastically reduces the time from design to finished parts.

By employing aluminum molds and leveraging advanced rapid tooling methods such as CNC machining and electrical discharge machining, manufacturers can produce molds in just a few weeks, compared to the months often required for traditional steel molds.

Additionally, the integration of detailed CAD data in the rapid injection molding process optimizes mold design and ensures precise, uniform cooling through efficient cooling channels, further enhancing production speed and part quality.

Cost Efficiency

Cost efficiency is a significant advantage of rapid injection molding, making it an attractive choice for many manufacturers.

By using aluminum molds and other softer materials for rapid injection molds, the mold production time and expenses are substantially reduced compared to traditional steel molds used in normal injection molding.

This reduction in mold costs allows companies to invest less upfront, which is especially beneficial for low volume production or prototype tooling.

Moreover, rapid injection molding minimizes material waste and lowers labor costs due to streamlined manufacturing processes and faster production cycles. These savings extend beyond tooling, contributing to a more economical production process overall.

Design Flexibility

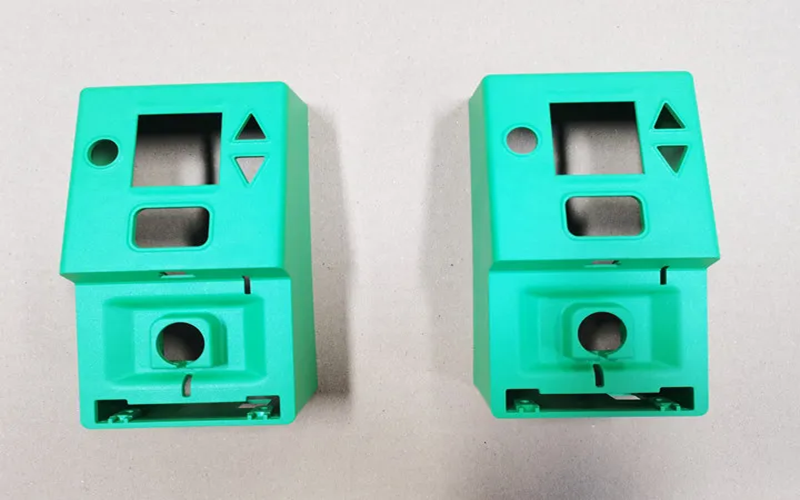

Design flexibility is a standout advantage of rapid injection molding, allowing manufacturers to quickly adapt and refine their products.

The use of rapid injection mold, typically made from aluminum or other softer materials, enables faster mold production and easier modifications compared to traditional steel molds.

This flexibility supports multiple design iterations during the prototype injection molding phase, helping engineers optimize part features, wall thickness.

Moreover, the rapid injection molding work is performed using standard injection molding machine, which ensures high precision and consistent quality throughout the production process.

Disadvantage Of Rapid Injection Molding

While rapid injection molding offers numerous benefits, it also comes with certain limitations that manufacturers should consider to make informed decisions.

Limited Mold Durability

One of the key disadvantages of rapid injection molding lies in the limited durability of molds made from softer materials like aluminum.

Unlike traditional steel molds, which are engineered for high volume production and extended tool life, aluminum molds tend to wear out more quickly.

The shorter mold life can increase costs if used beyond their optimal production capacity, as frequent mold replacement or repairs may be necessary.

Lower Tolerance

One of the limitations of rapid injection molding is the lower tolerance levels compared to traditional steel molds.

Since rapid injection molds are typically made from softer materials like aluminum, they may not achieve the same tight tolerances required for some high-precision applications.

This can result in slight variations in dimensions and surface finish between parts, which might be critical in industries demanding exact specifications.

Potential Surface Finish Limitations

While rapid injection molding offers many advantages, it is important to consider potential surface finish limitations associated with aluminum molds.

Compared to traditional steel molds, aluminum molds may not achieve the same high-gloss or optically clear finishes, which can impact the aesthetic quality of the final parts.

This is particularly relevant for products requiring a premium appearance or intricate surface textures.

Common Applications Of Rapid Injection Molded Parts

Rapid injection molded parts are widely used across various industries due to their versatility and efficiency.

Medical Devices

Rapid injection molding plays a crucial role in the medical devices industry by enabling the production of precise, high-quality parts with tight tolerances essential for medical applications.

This process supports rapid development cycles, allowing manufacturers to quickly produce initial prototypes and low-volume production tooling that meet stringent regulatory standards.

The ability to use production-grade materials ensures that the molded parts exhibit the necessary mechanical strength, thermal resistance, and biocompatibility required for medical environments.

Automotive Industry

The automotive industry greatly benefits from rapid injection molding due to its ability to produce durable, high-quality plastic parts with excellent thermal resistance.

This manufacturing process supports quick design iterations and prototyping, enabling engineers to test and refine components efficiently before moving to full-scale production.

Rapid injection molding also offers competitive pricing and reduces lead times compared to traditional injection molding, making it an ideal solution for producing complex parts such as interior panels, connectors, and under-the-hood components.

Consumer Electronics

Rapid injection molding plays a vital role in the consumer electronics industry by enabling the fast production of complex, high-precision plastic parts that meet stringent quality and aesthetic standards.

The process supports rapid prototyping and low to medium volume production, allowing manufacturers to quickly iterate designs and bring innovative products to market faster.

Additionally, the flexibility of rapid injection molding accommodates the use of various injection molding materials that provide the necessary thermal resistance and durability required in consumer electronics.

Rapid Injection Molding vs Traditional Injection Molding

Rapid injection molding and traditional injection molding are both essential processes in the manufacturing industry, but they serve different purposes and come with distinct advantages.

Traditional injection molding utilizes hardened steel molds designed for high volume production and long-term durability, making it ideal for mass manufacturing with consistent quality and tight tolerances.

However, the mold production process can be time-consuming and costly, often requiring several weeks or months to complete.

In contrast, rapid injection molding focuses on speed and flexibility by using softer materials like aluminum for mold production.

These rapid molds are quicker and less expensive to produce, significantly reducing lead times from design to part production.

While rapid injection molds may not match the durability or surface finish quality of standard molds, they excel in prototype molding, low volume production, and bridge tooling applications.

This allows manufacturers to test complex molds and designs efficiently before committing to full scale production.

Moreover, rapid injection molding supports faster design iterations and secondary operations, enabling quicker adjustments and refinements during the product development process.

Ultimately, choosing between rapid and traditional injection molding depends on production volume, budget, and the complexity of the molded parts required.

| Aspect | Rapid Injection Molding | Traditional Injection Molding |

|---|---|---|

| Mold Material | Softer | Durable |

| Production Time | fast | slow |

| Mold Cost | Lower | Higher |

| Production Volume | Low | High |

| Lead Time | Short | Long |

| Design Flexibility | High | Limited |

Summary

In summary, rapid injection molding offers a versatile, cost-effective, and efficient solution for modern manufacturing needs.

Its ability to produce high-quality parts quickly and at a lower cost makes it an invaluable asset across various industries, including automotive, medical devices, and consumer electronics.

By leveraging advanced rapid tooling techniques such as CNC machining and electrical discharge machining, along with the use of aluminum molds, companies can significantly reduce lead times and mold costs while maintaining tight tolerances and excellent surface finishes.

This process not only accelerates product development timelines but also supports multiple design iterations, prototype tooling, and low to medium volume production runs.

Ultimately, rapid injection molding empowers manufacturers to respond swiftly to changing market demands and stay competitive in the fast-paced manufacturing industry.