Packaging injection molding is a vital manufacturing process that revolutionizes the production of custom plastic packaging.

By injecting molten plastic into precisely engineered molds, this method allows for the fast, efficient creation of high-quality packaging components tailored to meet the diverse needs of various industries.

This introduction will explore the fundamentals of packaging injection molding, highlighting its types, Characteristics and broad applications.

What Is Packaging Injection Molding?

Packaging injection molding is a high-pressure manufacturing process used to produce custom plastic packaging by injecting melted plastic materials into a precisely designed mold cavity.

This process occurs within specialized injection molding machines that apply clamping force to keep the two halves of the mold securely closed during injection.

As the melted plastic is injected under high pressure, it fills the mold cavity completely, ensuring the final product forms with detailed features and consistent quality.

Packaging injection molding offers manufacturers the expertise and system capabilities to produce a vast array of packaging products, from small containers to complex multi-part assemblies.

Types Of Packaging Injection Molding

Packaging injection molding includes several distinct types, each tailored to specific packaging needs and product requirements.

Understanding these types helps manufacturers choose the most suitable method to optimize production efficiency and product quality.

Traditional Injection Molding

Traditional injection molding is a widely used method in packaging injection molding that involves injecting melted plastic material into a mold cavity under high pressure.

This process is highly effective for producing complex, detailed packaging components with consistent quality and precision.

The mold, typically made through CNC machining, consists of two halves that clamp together tightly, ensuring no material leaks during injection.

Once the cavity is filled, holding pressure is applied to compensate for material shrinkage as the plastic cools and solidifies, resulting in a solid, durable final product.

Thin Wall Injection Molding

Thin wall injection molding is a specialized packaging injection molding technique designed to produce lightweight, rigid plastic parts with very thin walls.

This method is particularly advantageous for manufacturing packaging products such as cups, trays, and containers that require reduced material usage without sacrificing strength or durability.

By using thinner walls, manufacturers can achieve faster cycle times and lower production costs, making the process highly cost-effective for producing high volumes of packaging components.

In-Mold Labeling (IML) Injection Molding

In-Mold Labeling (IML) is an advanced packaging injection molding technique that integrates labels directly into the molded plastic parts during the injection process.

This method involves placing a pre-printed label inside the mold cavity before injecting the melted plastic. As the plastic fills the mold, it fuses with the label, creating a single, durable unit that combines both packaging and branding elements.

This technique is widely used for packaging products that require vibrant graphics and long-lasting labels, such as food containers, cosmetic jars, and household goods.

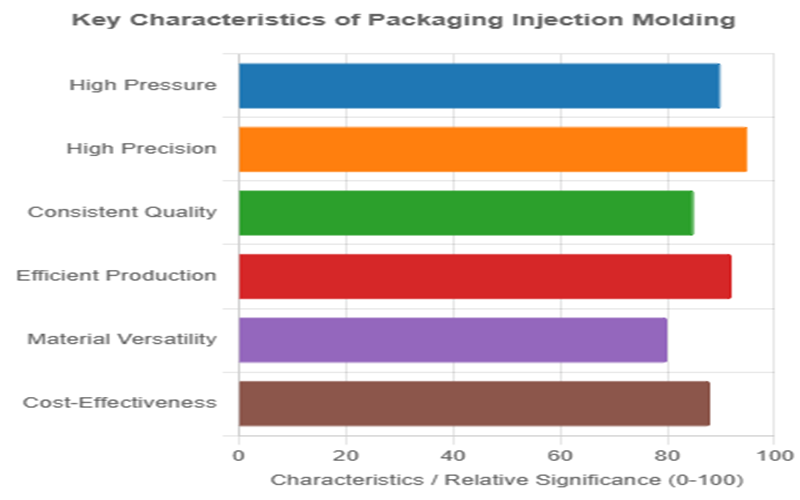

Characteristics Of Packaging Injection Molding

Packaging injection molding is distinguished by several key characteristics that make it an essential process in modern manufacturing.

High Pressure

In packaging injection molding, high pressure plays a crucial role in ensuring that the melted plastic is injected forcefully into every corner of the mold cavity.

This high injection pressure guarantees that the plastic material fills the mold completely, capturing intricate details and complex geometries required for custom packaging components.

High Precision

Packaging injection molding delivers exceptional precision in producing plastic packaging components.

The process utilizes advanced injection molding machines that precisely control injection pressure, temperature, and timing to ensure each part meets exact specifications.

This high precision results in consistent dimensional accuracy and fine detail reproduction, which is critical for packaging applications requiring tight tolerances and complex geometries.

Consistent Quality

One of the key advantages of packaging injection molding is its ability to deliver consistent quality across large production runs.

By precisely controlling critical parameters such as injection pressure, holding pressure, and hold time, manufacturers can ensure that each plastic part meets exact specifications.

This level of control minimizes variations in part weight, dimensions, and surface finish, which is essential for packaging products that require tight tolerances and reliable performance.

Efficient Production

Packaging injection molding is renowned for its efficient production capabilities, enabling manufacturers to achieve fast cycle times and high throughput.

The process allows for the simultaneous production of multiple parts within a single mold cavity, significantly reducing overall production time and costs.

Cost-Effectiveness

Packaging injection molding is renowned for its cost-effectiveness, especially when producing high volumes of plastic packaging components.

The process allows for rapid production cycles and efficient use of materials, significantly reducing per-unit costs.

By optimizing parameters such as injection pressure, hold time, and clamping force, manufacturers can minimize waste and energy consumption, further lowering overall production expenses.

Plastic Options For Packaging Injection Molding

Selecting the appropriate plastic material is essential for successful packaging injection molding.

Polypropylene (PP)

Polypropylene is one of the most widely used plastics in packaging injection molding due to its excellent chemical resistance, durability, and versatility.

PP’s ability to withstand high temperatures and resist contamination makes it ideal for packaging applications in the food, pharmaceutical, and consumer goods industries.

Polyethylene (PE)

Polyethylene is a versatile and widely used plastic in packaging injection molding, available in various densities such as high-density polyethylene and low-density polyethylene.

HDPE is favored for producing rigid packaging products like bottles and containers, offering excellent chemical resistance and durability.

On the other hand, LDPE provides flexibility and is commonly used for films, bags, and squeezable containers.

Polystyrene (PS)

Polystyrene is a popular plastic choice in packaging injection molding due to its lightweight nature and excellent moisture resistance.

It offers clarity and rigidity, making it ideal for packaging applications that require protective qualities and visual appeal.

Acrylic

Acrylic is prized in packaging injection molding for its exceptional optical clarity and resistance to UV light.

This plastic material is ideal for packaging applications where transparency and visual appeal are paramount, such as display cases, cosmetic containers, and high-end product packaging.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene is a popular plastic material used in packaging injection molding due to its excellent toughness, impact resistance, and dimensional stability.

ABS is particularly suitable for durable packaging components that require strength and resilience, such as protective cases, caps, and rigid containers.

Polycarbonate (PC)

Polycarbonate is a highly durable and transparent plastic material widely used in packaging injection molding for applications that require both strength and clarity.

Its excellent impact resistance and heat resistance make it ideal for producing packaging components such as clear containers, protective covers, and display cases.

Applications Of Packaging Injection Molded Products

Packaging injection molded products serve a vast array of industries and applications due to their versatility, precision, and cost-effectiveness.

Pharmaceutical Packaging

Pharmaceutical packaging demands the highest standards of safety, precision, and contamination prevention.

Packaging injection molding plays a crucial role in producing plastic containers, caps, and dispensers that meet stringent regulatory requirements.

These molded components ensure accurate dosing and secure sealing, protecting sensitive medicines and healthcare products from contamination and degradation.

Food Packaging

Food packaging produced through packaging injection molding ensures durability, safety, and hygiene, which are critical for maintaining product freshness and preventing contamination.

This process allows for the creation of diverse packaging products such as bottles, trays, lids, and containers that meet strict regulatory standards.

The precision and consistency of injection molding guarantee that each packaging component is produced with tight tolerances, ensuring a secure fit and reliable sealing.

Beauty Products

In the beauty industry, packaging injection molding plays a crucial role in creating custom containers, jars, and applicators that combine both aesthetic appeal and functional performance.

This process allows manufacturers to produce intricate designs with precise dimensions, ensuring that products like cosmetics, lotions, and personal care items are securely contained and easy to use.

The ability to mold components with consistent quality and tight tolerances helps prevent contamination and product degradation, which is essential for maintaining the integrity of beauty products.

Industrial Goods

Packaging injection molding plays a crucial role in the industrial goods sector by enabling the production of durable, precise, and complex packaging components.

This process supports the manufacturing of protective cases, containers, and multi-part assemblies that safeguard industrial products during storage and transportation.

Specialized Packaging

Specialized packaging injection molding caters to unique product requirements by offering customized solutions that enhance both functionality and aesthetic appeal.

This approach enables manufacturers to produce packaging with intricate designs, multi-part assemblies, and integrated features such as tamper-evident seals or ergonomic shapes.

Sustainability In Packaging Injection Molding

Sustainability is becoming increasingly important in the packaging industry, and injection molding is no exception.

One way to enhance sustainability is through the use of electric injection molding machines, which are more energy-efficient than their hydraulic counterparts.

Using recycled and biodegradable materials in the injection molding process can greatly diminish the ecological impact of packaging products.

Lean manufacturing principles further streamline production processes, reducing waste and enhancing overall efficiency.

Effective waste management practices, such as recycling programs and controls to reduce volatile organic compounds emissions, are essential for minimizing the environmental footprint of injection molding operations.

Conclusion

Packaging injection molding is a highly efficient and versatile method for producing a wide range of packaging products.

By carefully optimizing parameters such as injection pressure, holding pressure, and hold time, manufacturers can achieve gate freeze efficiently, ensuring no more material flows into the mold once the cavity is completely filled.

This precise control helps reduce defects and minimizes waste, making the process less time consuming and more cost effective.

Additionally, offering comprehensive services along the entire production line—from design and prototyping to final manufacturing—ensures smooth operations and high-quality outcomes.

Even a small amount of adjustment in process variables can significantly impact production time and product quality, highlighting the importance of expertise and advanced technology in packaging injection molding.

Looking ahead, the future of injection molding in packaging is promising, with continuous advancements in technology and engineering materials driving innovation.

Frequently Asked Questions

What Is Packaging Plastic Injection Molding?

Packaging injection molding is a process that creates custom packaging materials by injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

What Are The Latest Technological Advancements In Injection Molding Machines?

The latest technological advancements in injection molding machines include improved precision control, faster cycle times, enhanced energy efficiency with electric machines, multi-shot and in-mold labeling capabilities, and integration of smart automation for optimized production.

What Are Some Common Plastics Used In Packaging Injection Molding?

Common plastics used in packaging injection molding are Polypropylene, Polyethylene, Polystyrene, Acrylic, and Polycarbonate, each selected for their specific properties suited to various applications.

What Are The Key Benefits Of Using Injection Molding In Various Packaging Applications?

Injection molding offers key benefits in packaging applications such as high precision, consistent quality, efficient high-volume production, cost-effectiveness.

What Industries Benefit From Packaging Products?

Pharmaceuticals, health and beauty, food and beverages, industrial, and consumer goods industries benefit significantly from the efficient and versatile packaging solutions offered by injection molding.